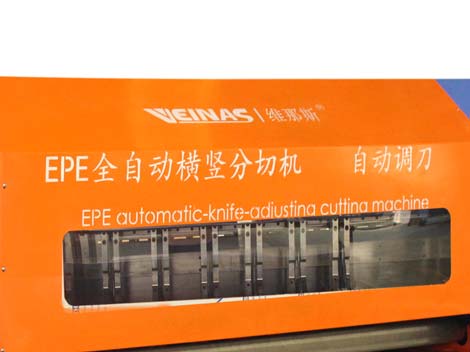

EPE Automatic-knife-adjusting Cutting Machine

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch. Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

HSC-03 | 2405*1050*1550 | 8 | 100-1300 | 5-5.5 | 2.5 |

2.Using Mitsubishi PLC from Japan and Weilun touch screen from Taiwan, which operates steadily with high precision.

3.Controlled by Electromagnetic clutch, the cutting speed is much faster.

4.It could reduce the wastage of the front and tail edging material. The wastage of this machine is about 10mm for both the front and tail edging material, but the wastage of similar machine in the market is about 60-90mm.

About the goods

About feedback

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts