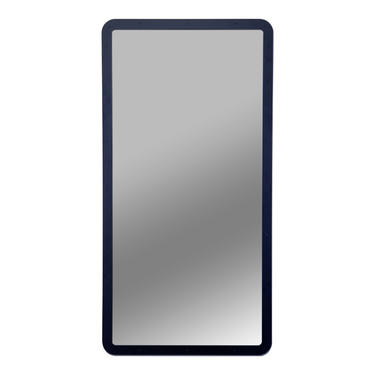

Export high-end round corner flat metal frame

Product description

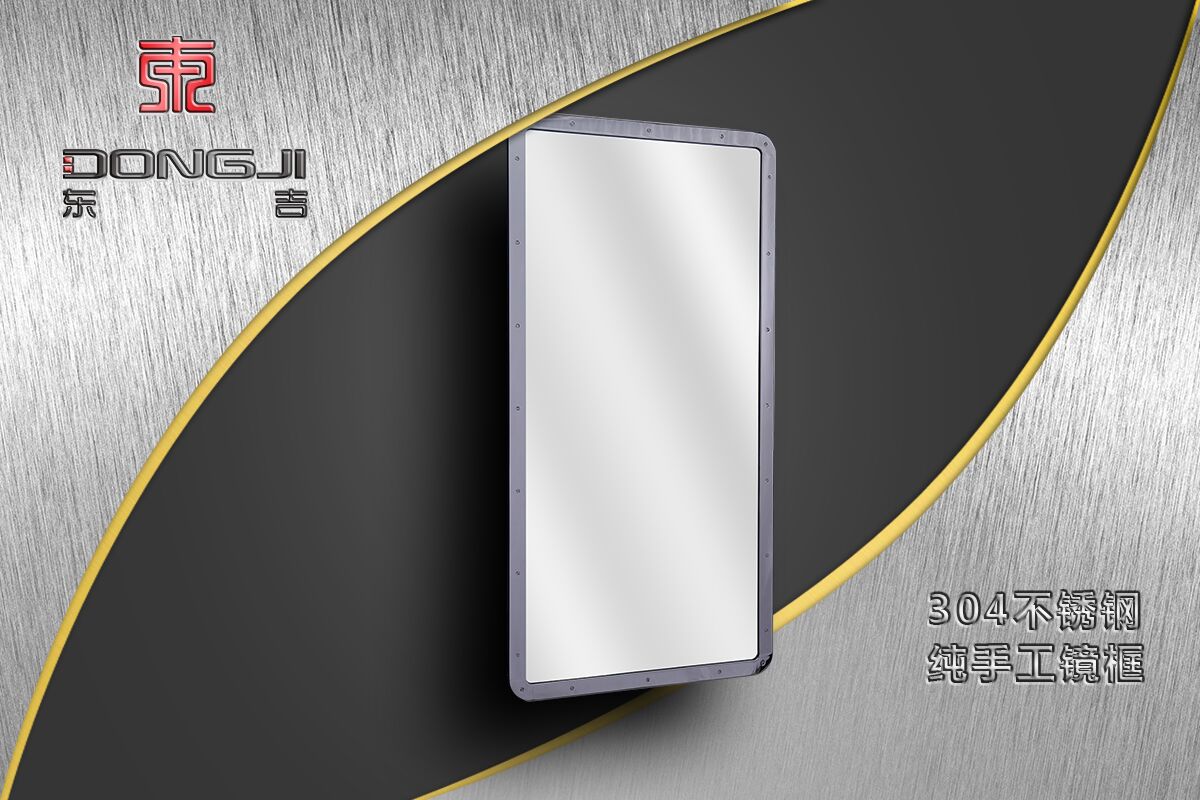

◪Titanium-plated metal material is 304 stainless steel, plate thickness is 4mm, plate width is 35mm, laser blanking, first single wire drawing and then whole frame welding, after the whole frame welding, grinding wire drawing, and then titanium plating.

◪The mirror is made of toughened glass. The mirror is chamfered around and 5 mm thick. The explosion-proof film is affixed on the back.

◪The backplane structure is the outer frame and the middle board. The outer frame thickness is 35 mm and the width is 26 mm. The middle board is composed of 5 to 7 wooden sideboards with a width of 60 mm and a thickness of 15 mm and a thickness of 10 mm.

◪The outer frame and the metal frame are fixed by screw, then the mirror is installed, and then the middle plate is installed. The middle plate and the outer frame are fixed by pulling nails, and the aluminum hanging bar is fixed behind the back plate. After the frame is assembled, it is inspected and corrected. After qualified, the surface is cleaned with alcohol and covered with transparent plastic bags. The frame is clamped with 6 to 8 plastic pads around the frame. It is placed flat in the carton. The lid of the carton is covered and fixed with packing tape.

Product process

Application

certificate

Business license

CE certificate

sira certificate

High-tech enterprise certificate (guangdong dongji intelligence)

A-level taxpayer certificate

Guangdong dongji intelligent equipment co., LTD. (science and technology award)

Contact

Supplier