Factory directly superior fireclay insulation lightweight bricks for furnace kiln

Provide me more informations you can ,I try to advice you detailed solutations for you !

Factory directly superior fireclay insulation lightweight bricks for furnace kiln

1. fireclay insulation lightweight bricks Details:

1.Made by high purity fire clay, by adding combustible, gas evolution method, or foam method.

2.Al2O3 content 30-46%.

3.Bulk density is 0.6-1.5g/cm3, crushing strength is 1.5-5.9MPa, thermal conductivity is 0.221-0.70W/(m.K) (1350°C)

4.Working temperature:less than 1300°C,Max working temperature:1200°C - 1400°C.

2. fireclay insulation lightweight bricks Technique data:

Item | insulation fireclay brick | |||

0. 6 | 0.8 | 1.0 | 1.3 | |

Al2O3 (%) | 40 | 40 | 40 | 40 |

Fe2O3 (%) | 1.5 | 1.5 | 1.2 | 2 |

SiO2 | 55 | 55 | 55 | 55 |

Bulk Density (g/cm3) | 0.6 | 0.8 | 1.0 | 1.3 |

Apparent Porosity % | 70 | 60 | 55 | 50 |

Cold Crushing Strength(Mpa) ≥ | 2.0 | 2.5 | 3.0 | 4.0 |

Reheating Linear Change (%)°C X 12H ≤ | 1300℃ -0.5 | 1350℃ -0.5 | 1350℃ -0.9 | 1350℃ -0.9 |

Thermal Conductivity(W/m.k)(1000°C) | 0.33 | 0.60 | 0.45 | 0.8 |

Max Service Temperature (°C) | 1200 | 1280 | 1300 | 1350 |

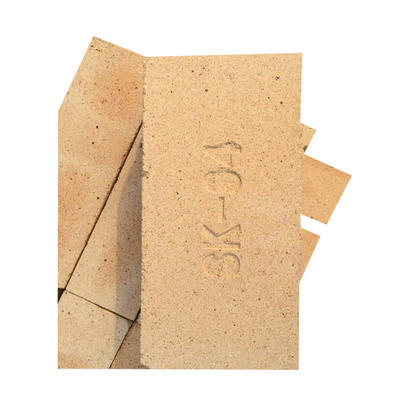

3.fireclay insulation lightweight bricks Product photoes:

4. fireclay insulation lightweight bricks Feature :

1.Low levels of iron and other impurities;

2.High refractoriness,but can not contact with the flame directly;

3.High porosity, low volume density, low thermal conductivity;

4.Good heat insulating effect and energy-efficient;

5.Good thermal shock stability;

6.Corrosion and erosion resistance;

7.Long service life.

5. fireclay insulation lightweight bricks Applications :

insulation fire brick can not be in direct contact with the flame.

It can be used as inner lining brick of industry kilns wall and industry furnance.such as blast furnace, hot blast stoves ,electric arc furnace,cement kiln,melting furnace,ignition furnace,flue,refining equipment,heating equipment and piping, regeneration device, gas furnace,soaking furnace,annealing furnace,heat reaction chamber and other thermal industrial equipment.

6. fireclay insulation lightweight bricks Shapes &Sizes:

Straight | Split | Arch | Wedge | Tile |

L×W×H(mm) 230×114×65 230×114×75 | L×W×H (mm) 230×114×25 230×114×32 230×114×37 230×114×50 | L×W×H/h(mm) 230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65 | L×W×H/h (mm) 230×114×65/45 230×114×65/55 220×114×75/45 220×114×75/55 220×114×75/65 | L×W×H (mm) 230×230×38 230×230×50 230×230×65 230×230×75

|

| We also can make brick according to customers’ drawing and requirements. | ||||

1.fireclay insulation lightweight bricks Process

2.Quality Assurance

Lite Refractory is committed to high quality standards for all its products and services. With its thirst on State of the art technology at every level and a wide range of products, Lite Refractory can provide ideal solutions for the stringent requirement of the customer. Backed by decade of experience in different industries, and close association with customers,Lite Refractory will always bring new products which will give better life and value to the user.

The quality assurance system consists of the following steps:

a.Inspection and Control of incoming raw materials:According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.Inspection and control of the process:During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Inspection of product Standardization of quality of each product by process control and experimentation.

d.Taking corrective measures whenever deviations are noted.

e.Quality audit by quality management.Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

By Following the above steps we maintain the quality within specification so that the materials perform as per expected norms.Qualified and experienced engineers back our quality assurance system. We have the most modern test facilities for precise testing at each stage. Further, regular quality audit carried out ensures product quality within required norms.ltd has been awarded ISO 9001 Certification.

By Following the above steps we maintain the quality within specification so that the materials perform as per expected norms.Qualified and experienced engineers back our quality assurance system. We have the most modern test facilities for precise testing at each stage. Further, regular quality audit carried out ensures product quality within required norms.ltd has been awarded ISO 9001 Certification.

fireclay insulation lightweight bricks Packaging

1.For size 230*114*65mm bricks ,10pcs/carton and 48 cartons/pallet,24pallets/20 feet container.

2.For size 230*114*65/55mm bricks ,12pcs/carton and 48 cartons/pallet,24pallets/20 feet container.

Shipping

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:3 days for common shape samples;15 days for special shape samples.Within 30 days for batch goods.

Payment Terms

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance before delivery or negotiations to solve.

2. MOQ: Usually 1Tons,Customers can order certain PCS for special brick.

3. Quality Warranty: 1 years,

4. Package Informations:1.On wooden pallets with plastic cover, 2.According to customer's requirements.

(1)Wooden pallet size:930*90mm,Load weight of each pallet:1.5-2.0 Tons.

(2)20 Foot Container can be loaded 25Tons,40 Foot Container can be loaded 28Tons.

Factory View

Henan Lite Refractory Material Co., Ltd is located in Zhengzhou Henan province,which is one of the main refractory production bases in China.

Pengfei Zhang the manager of our company,has been engaged in refractory material industry for more than 15 years.In the technological team there are more than 10 senior designers and engineers,more than 20 technicians.

The main equipments are:respectively two pieces of friction presses of 630T and 315T,two hydraulic vibration forming machines,three pieces of 1750℃high temperature gas shuttle kilns.

Product manufacture and supply:

(1)Different refractory bricks:Clay brick,High alumina brick,Light weight insulating brick,Corundum brick,mullite brick,Zirconia brick,Silica brick,Sillimanite brick,Magnesia brick,Magnesite carbon brick,Silicon carbide brick etc.

(2)Unshaped refractory:Castable,Ramming mass,Gunning mix,Mortar, calcium aluminate cement,Mouldable refractory,Refractory raw material etc

(3)Ceramic Fiber Product:Ceramic fiber board,fibre blanket,fiber paper,fiber cloth,fiber tape,fiber module etc.

(4)Refractory balls:High alumina ball,Alumina ceramic ball,Ceramic regenerative ball etc.

They are widely used in Iron and Steel, Nonferrous Metals, Building materials(Cement,Glass,Ceramic), Petrochemical, Energy & Incineration etc industries. Our products have been exported to India,Turkey,Vietnam,Malaysia and Kazakhstan etc.

Our Certificates

Customer visiting

Now customers from Pakistan,Russia,Saudi Arabia,Kazakhstan etc have visit company and factory!

Why Choose Us?

1.We are Alibaba Assessed 1 years Gold Supplier,but we have exported some years and our manager is engaged in refractory materials more than 15 years. He can supervise raw material,production,quality control,package,delivery easily to ensure the products are quality.

2.Large production capacity(3000-5000tons per month) ensure the fast production cycle after confirmed the order.

3.ISO9001 Certificate,100% QC inspection Before Shippment,and 1 year Quality Assurance.

4.Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

5.Free samples.Produce the products according to clients' requirements. To meet the refractory solutions, also can arrange technicians to customers’ plant if needed.

6.Quick reply.Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

Q1.What is the difference between Refractoriness and Working temperature ?

A1:Refractoriness:the refractory material withstands high temperature without melting and softening performance in the absence of load resistance.Usually working temperature is less than refractoriness about 350-400°C.

Q2.How are the products’ quality?

A2:The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q3:What is the Warranty for the fire brick?

A3:For all the brick,we have 1 years warranty.If any quality problems on our side occured in this period ,we will take on the shipping cost and replacement.

Q4.What is the service life of the bricks?

A4:The service life of different bricks is unlike.It also depends on your using condition and method.

Q5:Are you a manufacture or trader?

A5:To be honest we are a trader,but we have stable cooperation factories.And we can supply good pre-sale service, after-sales service.

Q6.Can we visit your company?

A6:Sure,welcome at any time,seeing is believing.

Q7. Do you provide samples?

A7:Yes, samples are available.

Q8. Do you accept OEM?

A8:Yes, we can do OEM.

Q9.What's the MOQ of trial order?

A9:No limit,We can offer the best suggestions and solutions according to your condition.

Q10.What are the payment terms?

A10:Usually T/T,but L/C,Western Union etc are available for us.

Q11. How long is delivery time?

A11:The delivery time will be determined according to the quantity of the order.

Q12.How about your company's certification?

A12:ISO9001 and Test Report,also we could apply other necessary certification.

Q13:Can we get support if we have our own market position?

A13:Please inform us your detailed mind on your market demand,we will discuss and propose helpful suggestion for you,to find the best solution for you.

How to Contact Us?

If you are interested in our products or have any doubts,Please

Send your Inquiry Details in the Below for free sample , Click "Send" Now!

Contact

Supplier