Factory price Ionpure EDI Module for Ultrapure Water for Lab Use

Auto Electric Cell Automatic EDI Module Deionized Water

Ionpure EDI Module for Ultrapure Water for Lab Use

Electrodeionization (EDI) is a process that uses ion exchange resins to absorb ions from a dilute water stream and then transports the absorbed ions through ion-exchange membranes into a concentrate water stream under the influence of an applied electro field. In the process,ion exchange resins do not need to regeneration via acid or alkali. This new technology could replace traditional Electrode ionization (DI) equipment, product ultrapure water whose resistance up to 18 MΩ·cm.

Advantages of EDI technology

A mixed bed ion exchange unit has to be regenerated by using acid and alkali, but an EDI system does not need such a process.

This is the fundamental advantage of EDI technology over the conventional ion exchange technology. However,

this advantage can be expressed into other aspects as listed below.

1. EDI process does not consume regeneration chemicals.

2. EDI process does not create waste water and much more environmental.

3. EDI systems do not require shutdown for regeneration.

4. EDI systems are smaller than mix bed ion exchange units.

5. EDI process provides water of consistent quality.

6. Operating expenses are lower than ion exchange units.

Applications of EDI technology

EDI typically may be used in any applications that require ultrapure water at a resistivity above 1 MΩ·cm. The typical industries that use ultrapure water include:

1. Microelectronic and semiconductor production.

2. Pharmaceutical and biomedical industries.

3. Chemical production.

4. High pressure boiler such as the ones in power plants

1. Dilute chamber is the space for the dilute stream (product water) to pass through. It is formed by a frame, one piece of

anionic ion exchange membrane on one side of the frame and a piece of cationic ion exchange membrane on the other side of

the frame. Inside the frame there is tightly packed with mixed ion exchange resins.

2. Concentrate chamber is the space for the concentrate to pass through. It is created by layers of two dilute chambers.

It is also formed by anionic ion exchange membrane, cationic ion exchange membrane and ion exchange resins.

3. Anolyte chamber is next to an anode and a catholyte chamber next to a cathode.

4. Electrodes, reinforcing plates, gaskets, bolts, and other necessary parts.

5. Power and connections.

Advantages of EDI module

Super EDI has the different advantages from other EDI modules as following:

1. EDI does not consume salts in operating and need much lower operating expenses.

2. EDI broadens the feed water limit adequately.

3. EDI does not need to recycle the concentrate, which makes the system much simpler.

4. EDI systems require little energy

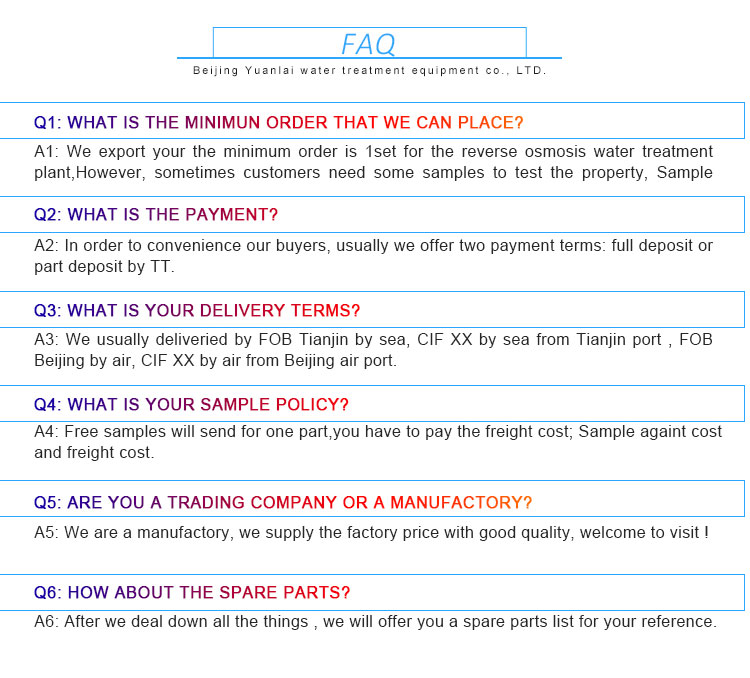

Operation conditions and specifications

The quality of feed water and other operation conditions greatly affect the success of EDI systems,

and may result in unrecoverable damages to the modules. Because of this, the quality of feed water has to be strictly controlled.

Each of the following requirements has to be met with normal operations and for the validation of its warranty.

Membrane specification

Table 3-1 EDI series and main operating conditions

Models | CP-500S | CP-1000S | CP-2000S | CP-3600S | CP-4500S | CP-5800S |

Operation Voltage (V) | 20-80 | 20-100 | 50-120 | 50-180 | 80-240 | 100-250 |

Operation Current (A) | 0.5-5.5 | |||||

Product Flow (m3/h) | 0.4-0.7 | 0.9-1.2 | 1.0-2.0 | 2.0-3.5 | 3.0-4.5 | 4.2-5.8 |

Concentrate Flow(m3/h) | 0.06-0.10 | 0.13-0.18 | 0.15-0.30 | 0.24-0.41 | 0.35-0.54 | 0.50-0.82 |

Electrolyte Flow(m3/h) | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

Contact

Supplier