/ Product description

EPDM is with excellent allround properties. It is of many advantages, for example, outstanding anti-ozone, excellent weather resistance, outstanding chemical resistance, resistent to polar reagent like brake fluid,strong acid and alkali,alcohol and so on.

The disadvantage is expanding too much in the ordinary mineral oil and second ester lubricating oil.

Temperature range:-60℃~+150℃.

/ Car tape real picture

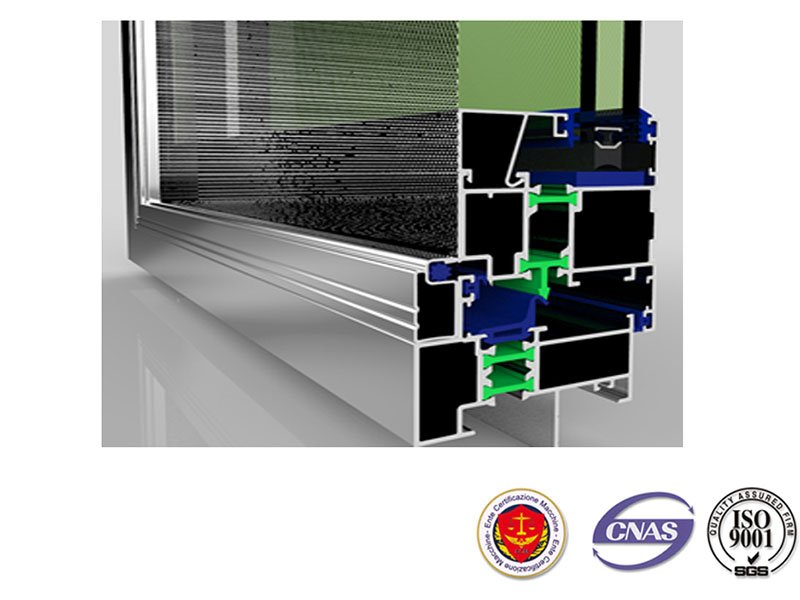

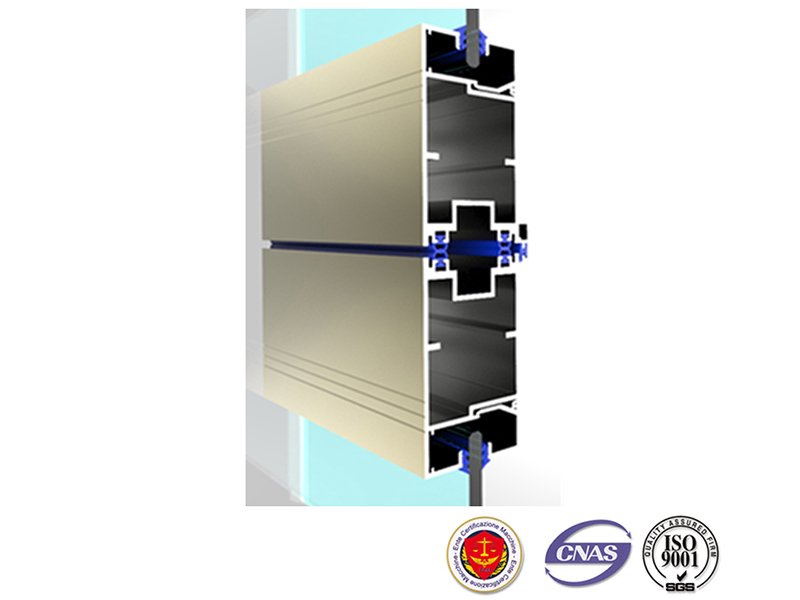

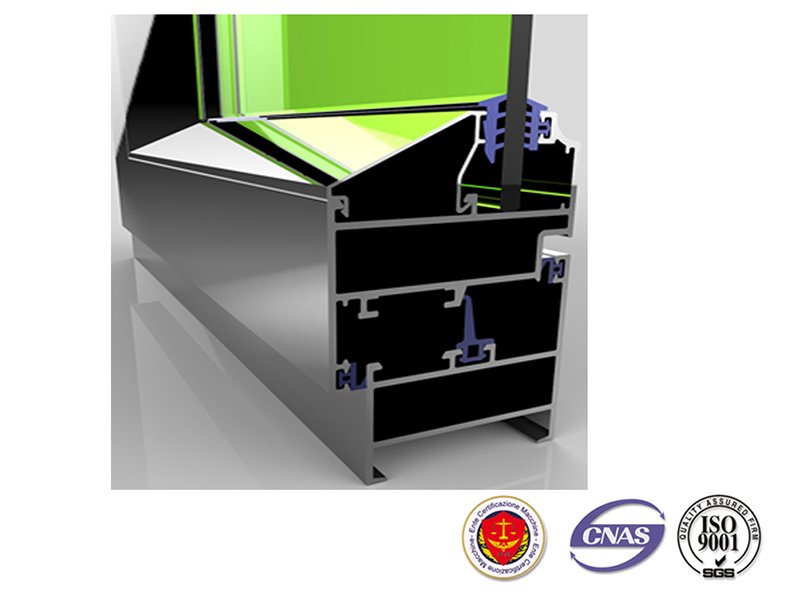

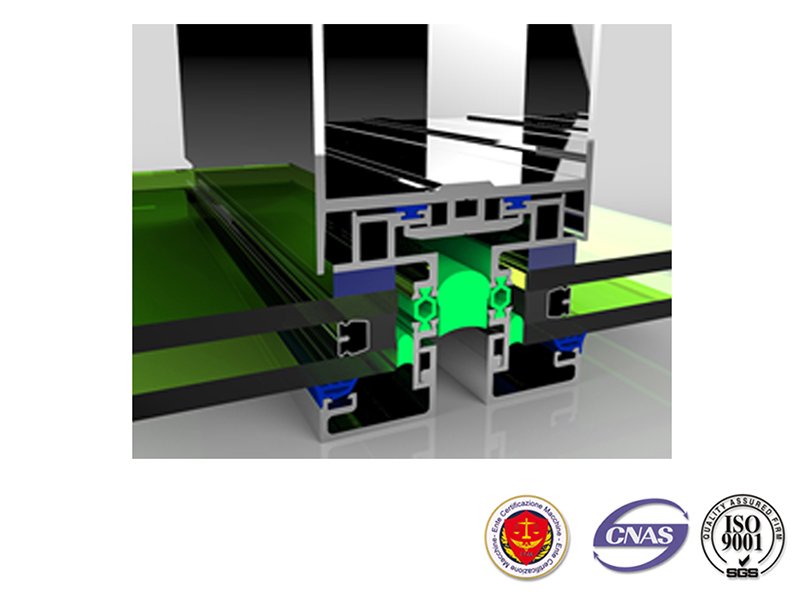

/ Product application

/ Product Material

Sealing Rubber Strip Specification

| Characteristics | EPDM | PVC |

| Basic Characteristics | Shore A Hardness | 70±5,60±5 | 65±5,70±5,75±5,80±5 |

| Tensile-strength (Mpa) | ≥5.0 | ≥5.0 |

| Tensile elongation (%) | ≥250 | ≥250 |

| Compression Set (100℃*22h)(%) | ≤35 | — — |

| Heat Aging(100℃*72h) (Tensile-strength and Tensile Elongation Variation (%)) | — — | <15,<30 |

| Heat Aging(100℃*168h) (Tensile-strength and Tensile Elongation Variation(%) ) | <25,<40 | — — |

| Weight Loss on Heating(%) | ≤3.0 | ≤3.0 |

| Low Temperature Brittleness(-20℃) | — — | Pass |

| Low Temperature Brittleness(-40℃) | Pass | — — |

| Product Performance | Usage Temperature(℃) | -50℃~120℃ | -20℃~100℃ |

| Flame Retardant | N/A | N/A |

| Ozone Proof | Excellant | Normal |

| Storage Life(Year) | 10-15 | 5-7 |

| Product Technics | Forming Method | Microwave Vulcanization | Extrusion Molding |

| Corner Joint Menthods | Vulcanized | Heat Weld |

| Color | Black | Multi-color |

/ production process

1. Mixing

Weighting-Mixing-Oping mill-Cooling

2.Extrusion

High-temperature setting-Micro vulcanization-Hot vulcanization-Cooling

/ Product design