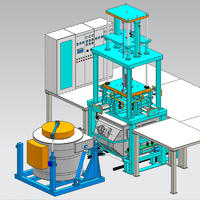

Faucets Sand Inner Core Molding

1. Basic information:

Model NO.: JD600

Customized: Customized

Automatic Grade: Automatic

Package: Wood Package

Origin: China

Control Type: PLC

Condition: New

Certification: CE, ISO 9001:2008,

Trademark: Jingda

HS Code: 8474809090

2.ADVANTAGES:

1)Over 20 years experience in brass casting equipment.

2) Competitive price and quality.

3) Auto working, easy operation, save labor cost.

4) Short delivery time.

5) Instant after sale service on line.

6)Machine components

1. Stability of equipment

The equipment is supported by a low center of gravity arc welded steel frame with sufficient span to ensure good stability of the equipment.

The mass inertia of equipment motion will affect the stability of equipment. In order to avoid the movement of the equipment caused by the unexpected vibration, the equipment is provided with bolt holes for fixing the equipment.

2.Design criteria for equipment dimensions

All components and fittings are dimensioned to allow for erosion and wear, providing sufficient strength for normal operation of the equipment.

3. Electrical safety

The three-phase power line drawn by the power grid leads to the switch through the special channel in the electric control cabinet, and the terminal of the power line is equipped with a special plastic protective cover . Any live wires and terminals carry a clear warning sign. All components in the electronic control cabinet adopt the protection standard of IP20.There are a series of special grounding terminals near all the group wires in the electric control cabinet. Each grounding terminal is connected to the same ground wire. The color of all the connecting wires in the electric control cabinet conforms to the provisions of current laws. All terminals are the same standard and the same

Fixed mode. All motors are designed with special elements for over-current and overload protection. The main coil of transformer is also overload protected by special magnetic heating element. Internal electronic components with self - overload protection measures. Electrical hazards can be completely eliminated if routine maintenance and use are carried out in strict accordance with the instructions.

7)APPLICATION:

Widely used in Brass, Copper //Aluminum alloy casting for Plumbing Hardware, Faucets, Valves, Car Spares, etc.

3. Main specifications and technical parameters:

| Greatest weight of sand cores | 32 KG |

| Biggest size of core box(L*W*H) | 530*480*280 |

| Left and right Itinerary of plunger | 125mm |

| The longest Itinerary of clamping when vertucal clamoping | 400mm |

| Equipment net weight | 650KG |

| Heating power | 13KW |

| Size of apperance of machine(L*W*H) | 1600*860*2000mm |

4. About the after- sale services

In the meantime, we own strong administrant and technical teams to ensure that our innovation and improvement ability can keep up with changeable market requirements. In order to satisfy our customers better, we can also make machines according to our customers' specific needs.

Our after-sale service is prompt and patient. Once you place an order, we are willing to give you support in installment and labor training. During the production period, if you meet any problems that you are not able to deal with, you could contact us. We will try our best to help.

5. Working Process:

Core box clamping---Compressed core box----Shooting sand---Shooting head back----heating-----Core –pulling return----Open core box----Ejection Mold

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts