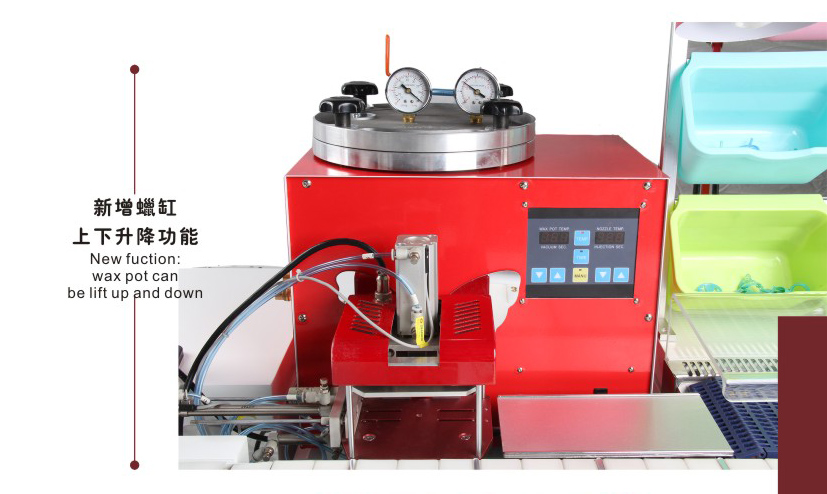

1.Adding wax cylinder up and down automatic lifting function: It can automatically identify and adjust the height of the wax nozzle (nozzle) to make the film accurately aligned.

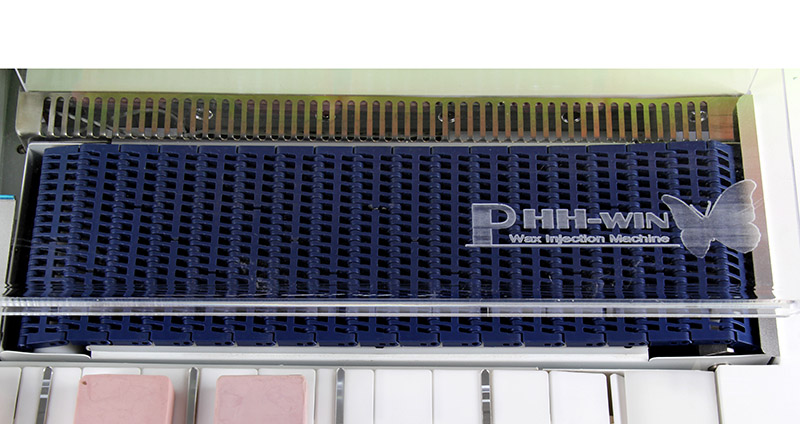

2.Using RFID (wireless communication chip) technology, the computer automatically recognizes the parameters of the film, the chip can be recycled indefinitely.

3.New sectional air pressure function: It can be upgraded from three-stage air pressure to nine-stage air pressure, and can simultaneously inject nine different air pressure adhesive films.

4.Using condensate recovery technology, no drainage, cooling and power saving, is a must-have model for rapid production.

Generation 7 intelligent induction auto wax injection system

❈ Product description

Machine property

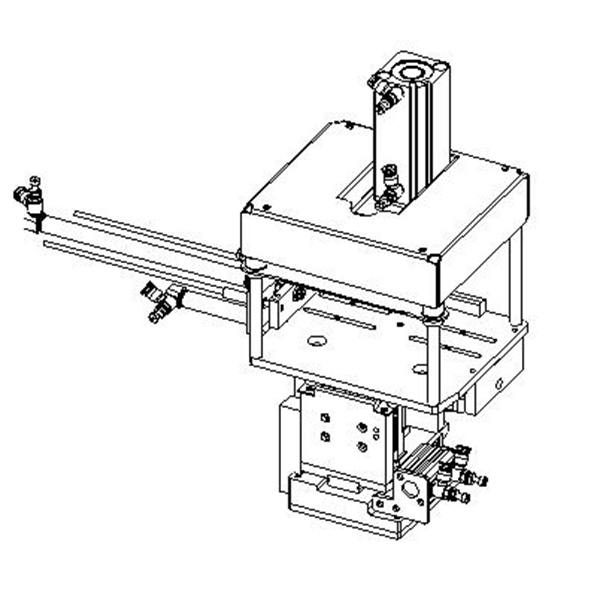

◪1.The sensor can recognize the height of Nozzle and align the rubber mold to the Nozzle precisely.

◪2.The chip-free bar code can also be used to set the parameters of the systemto mix the film with the chip film.

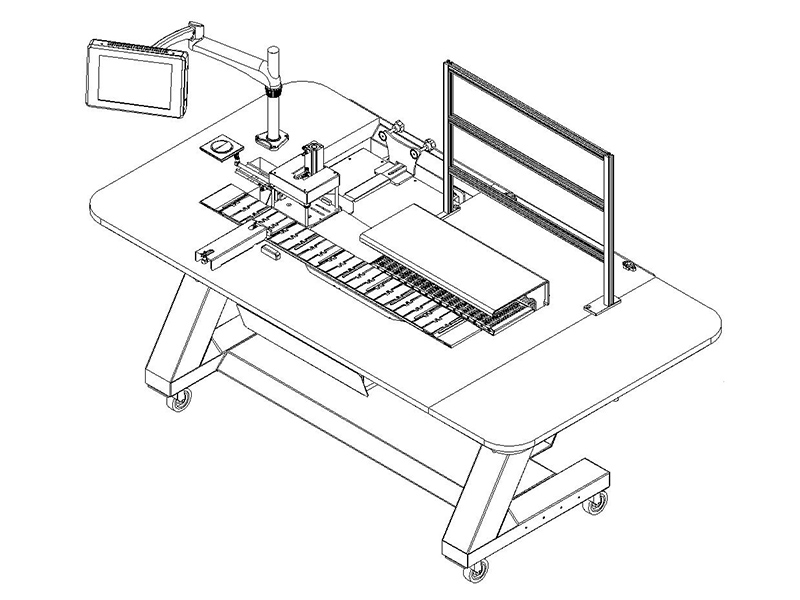

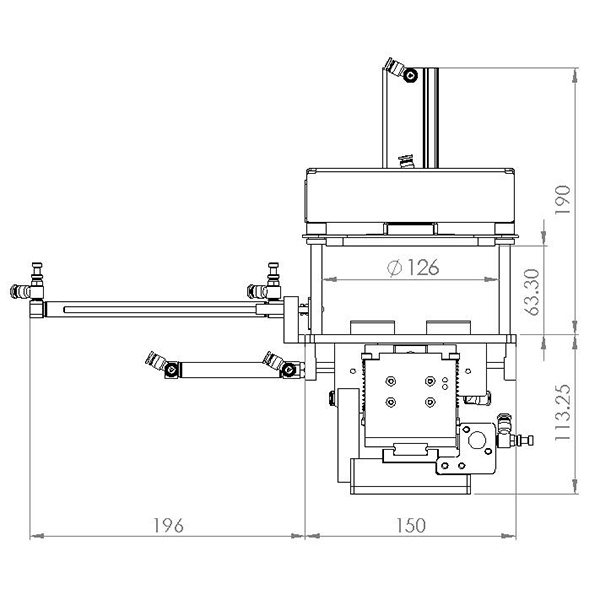

◪3.Manipulator is compatible with rubber mold in size : 11CM*10.5CM*5.5CM.

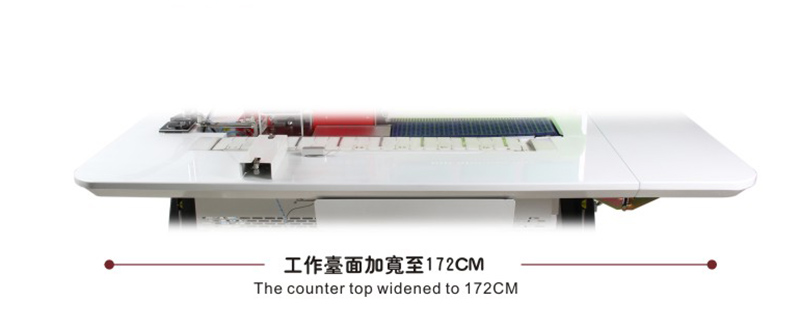

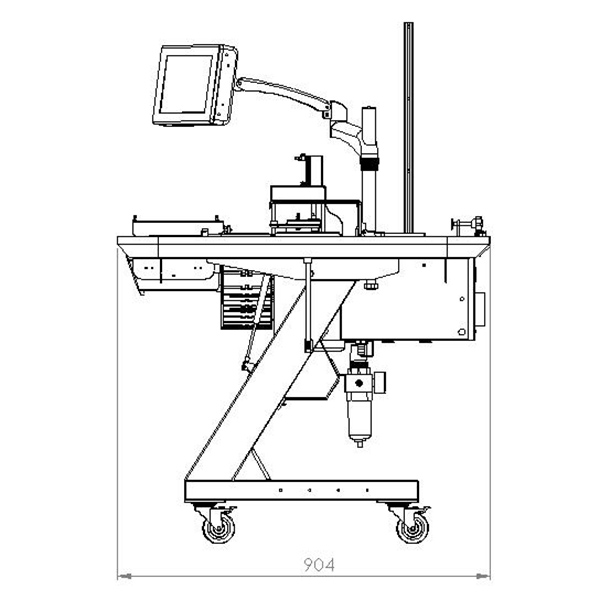

◪4.Counter-top is wider and longer, allowing the operator to have more space, and the leg support can be folded to 65cm high.

◪5.Touch screen is increased to 10 inch wide with LED at the bottom, to make operator easily scrutinize and check the wax mold quality.

◪6.LED on belt conveyor make the counter-top lighter and reduce the eyes fatigue.

◪7.No chip pressure segment number: 3 sets can be set, the three groups according to the color fast switching.( Upgrade 9 stage pressure).

◪8.New manipulator can manually adjust the center pointefore and after the die.

【voltage:】220V

【power:】400W-600W

【frequency:】50HZ

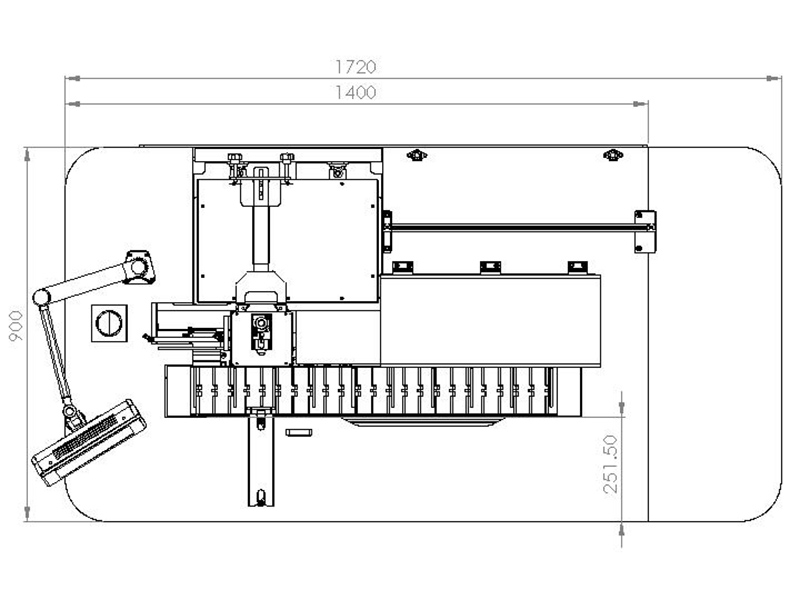

【overall size:】172CM*92CM*116CM

【Rubber mold size range:】Min:6CM*3.5CM*1CM ; Max:11CM*10.5CM*5.5CM

【G.W :】220KG

【wax injection parameters :】A. clamp pressure: 50-400PA ;B. injection pressure: 20-250Pa; C. vacuum time : 0-100S, D. injection time : 0.5-100S ;E. Cooling time

❈ New Configurktion

Rubber mow size max: 11cm*10.5cm*5.5cm

Standard configuration

◪1.1 wax pot.

◪2.One 10 inch wide touch screen( Led light at the bottom),both Chinese and English version available.

◪3.one clamp.

◪4.one computer host( including belt conveyor, high gloss counter-top, foldable leg support).

◪5.one set cooling system with LED.

◪6.2 white fluorescent (with bulbs).

◪7.80pcs chips, 4 nozzle beads, 4 brass mold.

❈ Technical Data

Parameter | Generation 6 | Generation 7 | PHH-MINI |

Equipment size (L*W*H) | 1720*904*1262 mm | 1720*904*1262 mm | 1180*892*1179 mm |

Net weight | 134 kg | 135 kg | 76kg |

Power supply | AC220/50Hz Can be changed according to customer requirements | ||

Power consumption (full load) | 1100 W | 1100 W | 700 W |

Pressure repeatability | ±0.5% | ±0.5% | ±3% |

Air pressure requirement | 6~12 Kg/cm2 | 6~12 Kg/cm2 | 6~12 Kg/cm2 |

❈ Drawing and Size

Contact

Supplier