GreenLatrine Composting Toilets in North America

Talk about the products

The main material is ABS, the designer said the toilet walls are 3/16 of an inch. Very thin. Can machining do that? Or maybe they don't need to be that thin? He was suggesting a 3D print, with webbing to reinforce certain areas for strength. Of course the customer were interested in the most economical solution that works, comparing to SLA 3d printing, for these big and heavry parts, and beeter for structure, CNC machining is recommended.

Talk about the Client

One of the world's leading R & D and production of GreenLatrine Composting Toilets company, the manufacturers need to test a model of the product function and appearance, because of the unique function, it does not allow the air and flies into, and good internal circulation, under certain conditions, is not a small convenience to people's life this makes the products. The market response has been good.

What's the Challenges

There are still details being worked out. A round rubber gasket seal will be placed between the lid and the seat, and a nitrile gasket ring will be installed between the other parts, to make it all airtight. Is it a problem to cut a notch (or maybe called a channel) on the underside of the lid, to hold a gasket? We will have this in the drawings of course. But they asked me if you could accomplish this. Let’s look at how we did it.

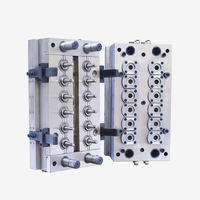

CNC Machining

We made amost the model parts using CNC Machining, For some of the large parts, no way to shape, our engineers will be cleverly split, after forming sticky together, after painting, completely invisible.

Contact

Supplier