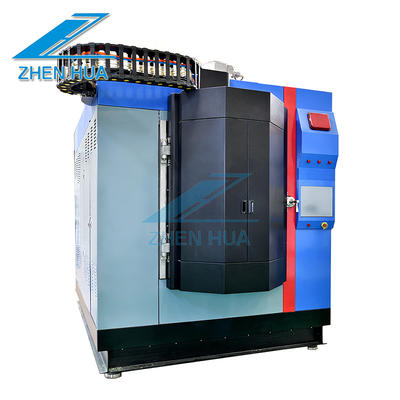

High-End Plastic Part Decorative Film Coating Machine FM1819

FM1819 vertical double doors evaporation decorative film coating equipment is a special equipment for evaporating aluminium, indium or indium tin oxide. The structure is vertical double doors, which with fast coating speed, make bright color coating, the coating is difficult to be contaminated.

Question 1: What products does this coating equipment apply to?

Answer: Evaporation coating equipment is mostly suitable forplastic products and glass products, such as plastic parts ofmobile phones (NCVM process), cosmetics packaging, winebottle caps, plastic toys, resin drills, plastic decorations, glasscup bottles, etc.

Question 2: What kind of coating process does this equipment use?

Answer: Evaporative coating equipment through aluminium or indium metal coating on the surface of the product,coating restriction 150-200 nanometer thickness of metal film, and then with the spraying process to make the product surface effect more beautiful and more effective.

Question 3: What effect can this coating equipment achieve?

Answer: Evaporative coating equipment can make white silver (aluminium), gray black (indium/indium tin alloy) or rainbow colorful effect on the surface of the product, or realize any paint color and pattern on the surface of the product through spraying process.

Question 4: How long is the production cycle time of this coating equipment?

Answer: Zhenhua evaporation coating equipment is a double-door design, to achieve synchronous production and loading of products, improve production efficiency. The coating equipment is equipped with superior performance vacuum pump pumping system and evaporation system. The production time of a single furnace is about 8 minutes. It is very efficient and the rate of good products is very high.

Question 5: How long will the delivery time of this coating equipment be? What's the price?

Answer: The delivery time of evaporative coating equipment is about 40 days(Time is for reference only, depending on the actual situation when purchasing the equipment). The price of the equipment is very affordable and the quality of the equipment is very superior. Welcome to consult our salesman for detailed discussion.

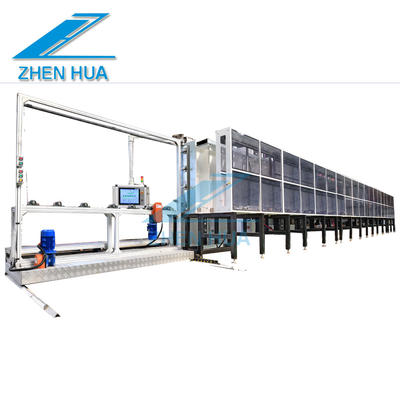

Normal Evaporation Coating process

Detailed product parameters

| Model | FM1819 |

| Inner size of vacuum room | Ф1800*1950mm |

| Equipment Data | Weight:12 Tons,Power:55KW, Voltage:380V |

| Film Forming | Metal film, raindrops film, dumb film, alluminium film, drawing film, colorful film, wrinkle film, bright film. |

| Coating Technology | Vacuum Evaporation Coating |

| Substrate | ABS, PS, PP, PC, PVC,Nylon, plastic, Metel, Ceramics,etc. |

| The material of chamber | Stainless steel |

| Coating Feature | Decorative film,bright color, not easy polluted, good uniformity |

| Control system | Manual,Semi-automatic, Fully automatic |

| Operation system | Touch screen+PLC |

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts