High Precision Machining CNC Copper Machined Parts

High Precision Machining CNC Copper Machined Parts

Applicable Material: copper, brass, aluminum/zinc alloy, iron, steel alloy, steel, and stainless steel

Surface Treatment: polishing, zinc plating, nickel plating, chrome plating, anodizing, Black, Nitrogenation.

Packaging: Standard package/ Pallet or container/ as per customized specifications.

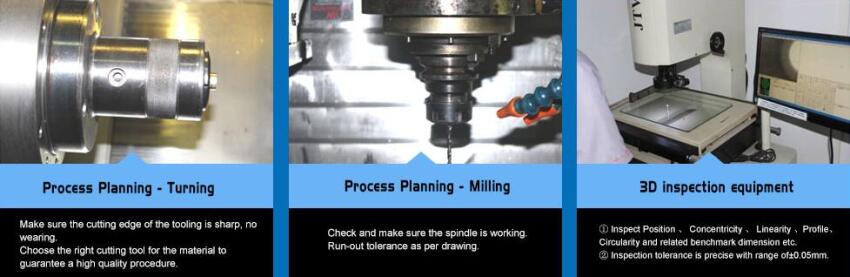

Factory Equipment: 4-axis CNC Machining Center, CNC Lathe, High Speed Electric Spark Puncher, Milling Machine ,Grinding Machine, CNC Lathes , Wire-cuts, Laser Cuts , CNC Shearing Machines ,CNC Bending Machines, etc.

Quality Control and Detection:

Our QC department work is inspection and final inspection. We promise you as below:

1. Check the raw material before the production.

2. Have inspection during the production.

3. Make 100% inspection before the shipment.

Coordinate Measuring Machine, Calipers, Microscope, Micrometer, DEM, Height Meter and 00 level

Equipment: Marbel Panel, Ring Gauge, Three Pin, Thread Gauge.

Usage: Heavy machinery, Marine equipment parts, Vehicles, Printing machines, Food, Processing machines, Textile machines, Electronic machines, etc.

Production Output: Based on customer's drawing or samples. Usually 300.000 pieces/ month

Experience: Over 10 years of professional; OEM service

Lead Time: usually based on customer's drawing or samples.

File Formats: Pro/Engineer, AutoCAD(DXF,DWG), PDF, TIF , UG, Mastercam , Caxa, Pullmill, etc.

Our advantage:

1. We are factory providing CNC service for more than 10years, specialized in stainless steel components

2. Handling components of very tight tolerance and very complex geometry

3. Low MOQ (1pcs is even acceptable in some special conditions)

4. Offering free and quick prototyping ( normally 1 week)

5. Sharp on time delivery

6. Top quality guaranteed by skilled workers, managing system and status of facilities.

7. A series of secondary service available, like casting; forging; welding; heat treatment etc.

8. Offering consultancy service on components machining

9. Customized size and spec /OEM available

10. Guangzhou, Foshan, convenient transportation.

Our Product List:

Contact

Supplier