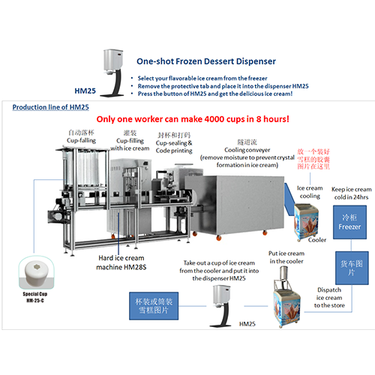

HM25APL one shot automatic Filling production line

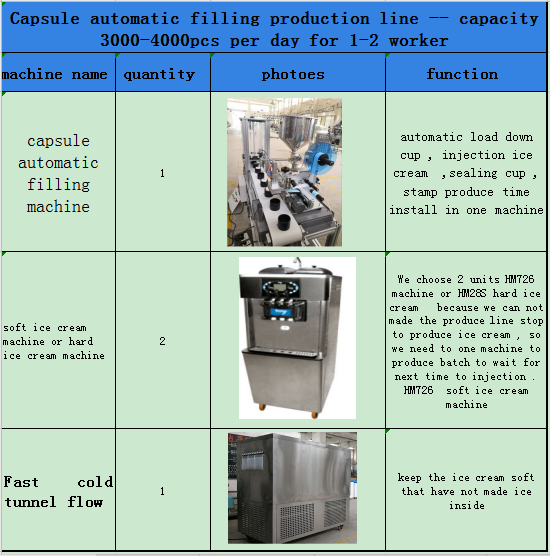

Capsule Automatic Filling Production Line

Capsule Automatic Filling Production Line|Product specification|Product Features

Product specification:

The One-Shot machine has changed all the rules for dispensing frozen desserts including ice cream, frozen yogurt ...... One-Shot machine is the real game changer. There is no need to be locked into the legacy of soft serve technology , and you also can reduce the complications of the ice cream factory. The associated sanitizing nightmare, soaring energy costs, variable quality and product integrity and substantial waste will not be a question.

Product Features:

A: automatic filling capsule machine

1. This produce line we design base on 3000-4000pcs every day base on 8-10 hours working time ,

Use one guy to work it . produce one cup about 6 second .

2. Cup volume each time can keep 72pcs ( 9pcs X 8 line )

3. Produce line that keep 18pcs cup holder .

4. Injection machine connect with soft ice cream machine direct inject ice cream into the cup and made ice cream not easy melt.

5. sealing paper each roller about 1500pcs

6. Add one stamp produce day .

B: soft ice cream machine & hard ice cream machine

We choose 2 units HM726 machine because we can not made the produce line stop to produce ice cream , so we need to one machine to

produce batch to wait for next time to injection .

C: Fast cold tunnel flow

1. The machine inside choose stainless steel conveyor that is Secondary transport , the first send ice cream inside chiller , second Freezing while conveying ice cream.

2. The compressor is 5 ph bigger company , it can pass temperature about -18C .

3. Add two windows to observe whether the internal operation of the machine is normal.

4. The conveyor speed can adjust it , Can complete a circle in 5-20 minutes , base on your quantity adjust it .

5. Machine size :1.3 X1.6X0.8m

Document:![]() 16025788495560.pdf

16025788495560.pdf

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Air-Compressors & Parts