HM706B ice cream maker

Table top ice cream machine

Table top ice cream machine|Product Features|Soft Serve Freezer and Frozen Yogurt Freezer|Product Specification

Product Features

Hommy has a professional team to do product design. There are professional refrigeration engineers, software engineers, and structural engineers to ensure that the product quality is stable and durable. At the same time, the personalized design is added to facilitate future after-sales service. Hommy ice cream machine is worthy of trust.

Soft Serve Freezer and Frozen Yogurt Freezer

Twin Twist, Pre-cooling, Mixer, Counter, Heat Treatment, Defrosting, Disinfection, Remote monitoring system

Features

•Product offering: Offer all popular soft serve variations from ice cream to low or non-fat frozen yogurt.

•Flavor: Serve two separate and one twist flavors.

•Mix hopper: Two 13 litter capacity (13.7quart, 3.43gallons)

•Freezing Cylinder: Two 2.8 litter capacity (3.0quart, 0.74gallons)

•15`` color touch screen tablet controllor with Android system.

- Safety ensure: After setting all the parameters as required, lock the control board and the settings can not be changed by others.

Functions:

•Pre-cooling system maintains mix below 5℃ during auto & standby modes.

•Mixer keeps mix uniformity in the hoppers.

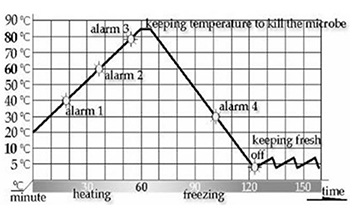

•Heat-treatment provides a daily cleaning routine to maintains product according to quality and safety standards up to two weeks before complete cleaning with disassembly.

•Defrosting

- Production defrosting rapidly melts the product in both cylinders and then goes back to production mode to reproduce.

- Washing defrosting rapidly melts the product in the cylinders that significantly reduces leftovers before cleaning.

•Disinfection

- Special function that makes sanitizing process semi-automatic and easy.

- No disassemble the machine to clean the throat block unit, air-pump unit, beater and cylinder.

•Counter allows the operator to view number of servings dispensed.

•Remote monitoring system:

- Connect with wifi, which allows you to check the date online.

- To timely discover the machine failure and directly send working diagnosis message to the facotry mnitoring center in order to solve the problem more quickly.

- To monitor the real-time sales volume as well as liquid level in the hoppers, which alerts to add material.

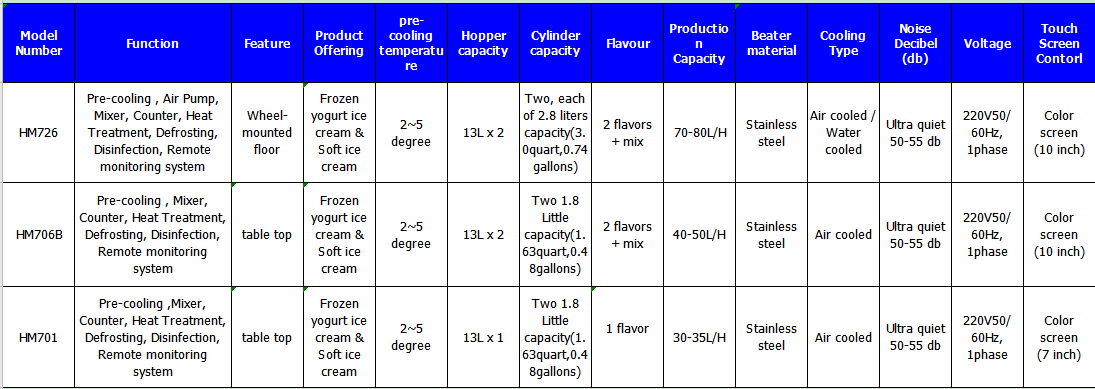

Product Specification

Hommy has a professional team to do product design. There are professional refrigeration engineers, software engineers, and structural engineers to ensure that the product quality is stable and durable. At the same time, the personalized design is added to facilitate future after-sales service. Hommy ice cream machine is worthy of trust.

1. Expansion tube

The function of the expansion tube is to blow air into the cylinder and mix with the ice cream to increase the expansion rate of the ice cream, which is softer and more delicious when you eat it. The expansion rate of the expansion tube is 30%-45%, and it has three different holes for customers to adjust the amount of air intake, which is convenient to clean and simple to operate.

2. Leave sensor

Leave sensor have Second stage, the first stage of missing material level alarm, the second stage of automatic shutdown. When you receive the first message, you have some time for you to add material no need let the machine stop to work it.

If you sell out ice cream at night the system automatic setup Pasteurization : Can kill the bacteria that produce inside the machine from -5℃ → 65℃→ -5℃process ( disinfect the loading cylinder and raw material inside,then refrigerate to booking status ). so you can keep the machine each 14 days one time.

The control panel clearly shows the internal functions of the machine. At the same time, the machine also reminds the cleaning function, adding more humanized functions, we are also welcome to do OEM.

Mix uniformly. High-speed mixer in hooper keeps the material flowing in hopper in case of frosting. The ice cream will be more smooth after mix completely with air.

Install the ice cream machine correctly. The distance between the exhaust port behind the machine and the wall is 1 meter for ventilation, but in fact, it is impossible to achieve this situation in our storage place. Hommy designed a new exhaust duct for daily use to exhaust hot air. To the top, it can satisfy more places without occupying space.

Document:![]() 16027509944616.pdf

16027509944616.pdf

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Air-Compressors & Parts