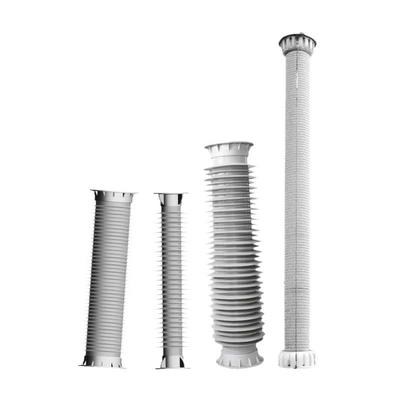

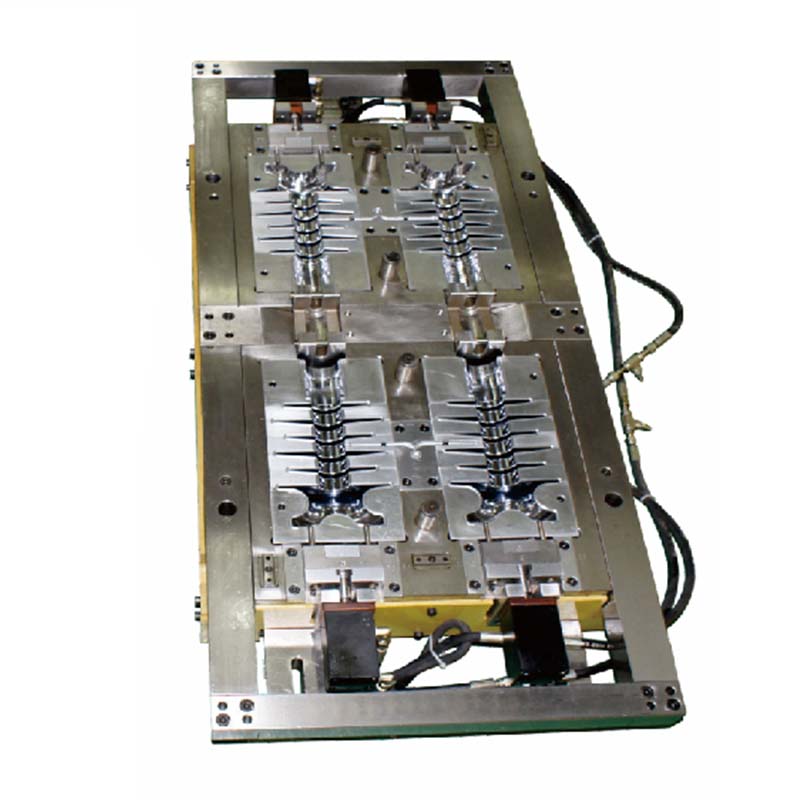

Hollow Core Insulator Mould used in conventional substation

Hollow Core Insulator Mould

This kind of mould can produce Hollow Core Insulator used in conventional substation, whose volatge can reach 500 kv.

We can provide mould according to following requirements:

According to the mechanical strength of product, the diameter of core rod ranges from φ80 mm to φ4600 mm.

According to the electrical performance of product, the cavity length ranges from 300 mm to 2300 mm.

Long product can be injected step by step.

SUCCESSFUL CASE

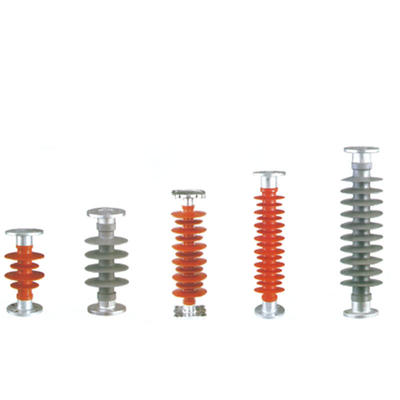

110kv-150kv Hollow Core Insulator

220kv-330kv Hollow Core Insulator

500kv Hollow Core Insulator

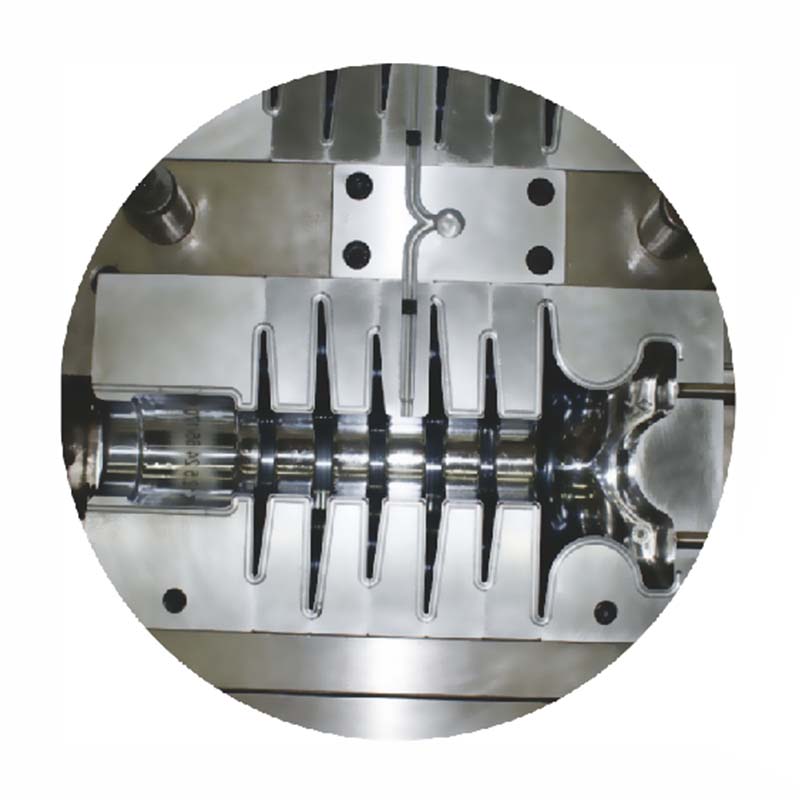

MOULD CHARACTERISTICS

The shed block of mould cavity is made of S136H, the material of high-strength stainless steel, which can makethe service life of the mould up to 100,000 cycles.

After heat treatment, electroplating and polishing for shed block, the surface of produced composite insulator is very smooth and beautiful.

Unique design of vent can easily tear off the edge fin of produed composite insulator to reduce the appearance treatment process.

Provide the best number of mould cavity and automatic demoulding device according to customers'needs to maximize the production efficiency.

Provide cold runner block device according to customer needs to increase output and reduce waste of raw material.

In order to facilitate the users using and maintaining mould, we will equip each set of moulds with operating manual. The manual contains information on the structure of moulds, disassembly and assembly of moulds,maintenance of common faults, etc.

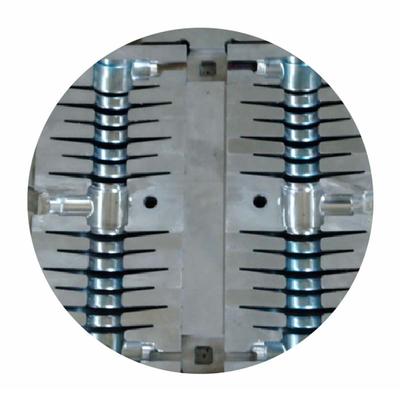

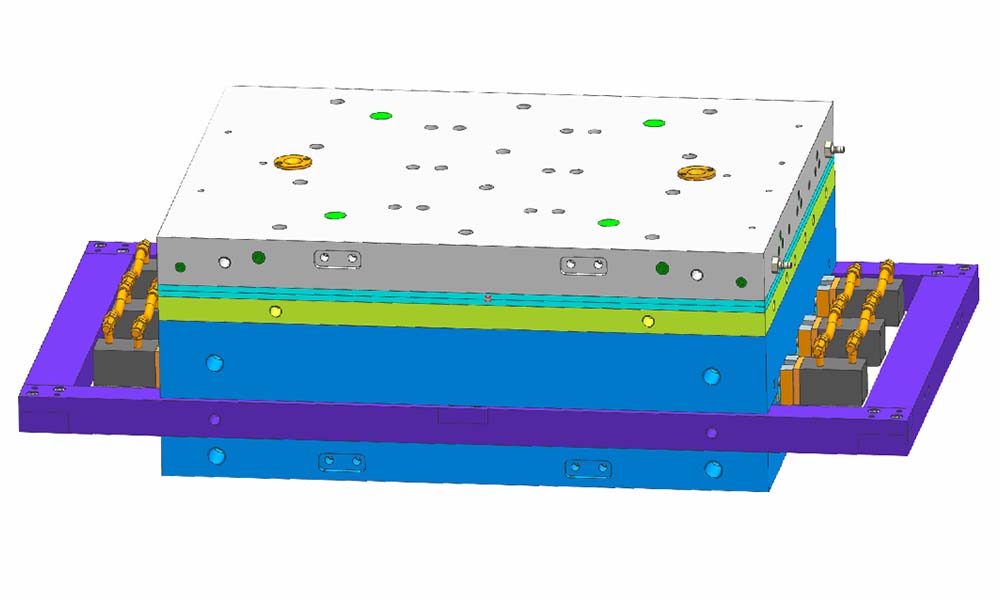

INTRODUCTION OF COLD RUNNER BLOCK DEVICE

Characteristics

By changing the position and number of injection nozzle of injection molding machine, one mould with multi-cavity can be realized to increase output.

By changing the position of injection nozzle, the distance between injection nozzle and product cavity can be reduced to reduce the waste of raw material.

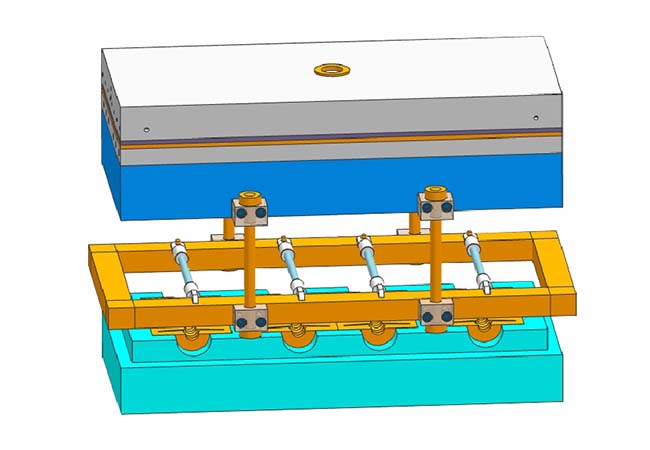

STRUCTURE

The cold runner block device consists of three parts.

1.Runner plate:

It has a circulating water pipe inside , which can keep the temperature down while working . so , it is always in a low temperature working state to ensure that rubber will not vulcanize and thus cause blockage.

Through scientific design, it can change the position and quantity of injection nozzle and ensure the balance of injection at each injecton nozzle.

2.Heat insulation plate:

It is composed of asbestos insulation plate and resin insulation plate, which can minimize heat transferring from heating plate to runner plate, and it has high strength so that it is not easy to break.

3.Heating plate:

It is used to provide heat for mould, so that the temperature of mould can reach and stabilize at the vulcanization temperature of rubber.

MOULD PRODUCTION PROCESS

1-Product analysis

2-Mould design

3-Incoming inspection

4-CNC processing

5-Heat treatment

6-Shed block finishing

7-Fine grinding

8-Electroplating and polishing

9-Assembling

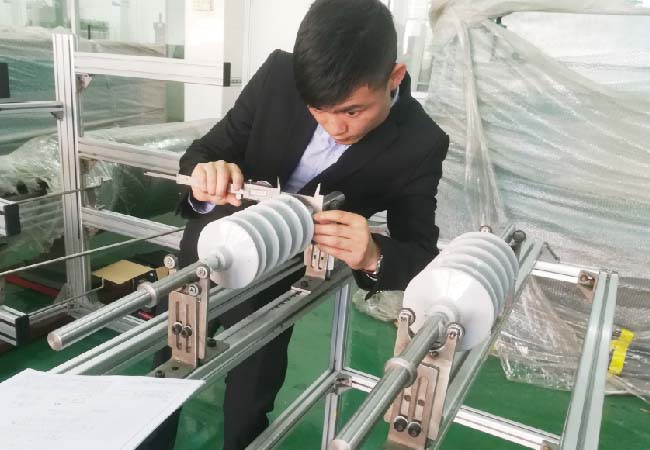

10-Mould test

11-Sample inspection

12-Package

Contact

Supplier