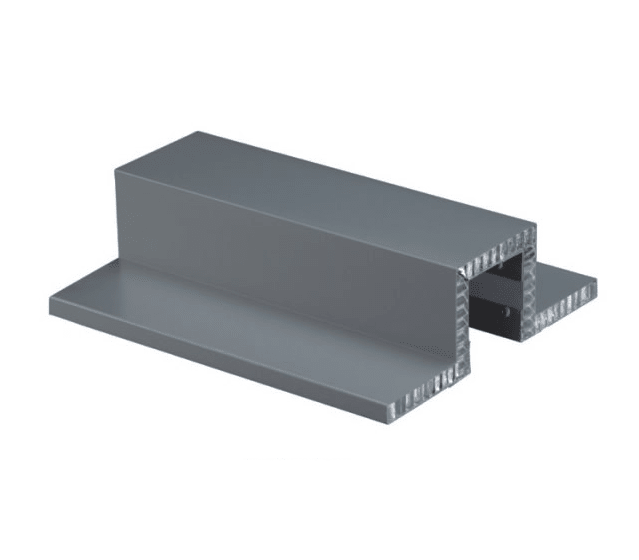

Honeycomb panels

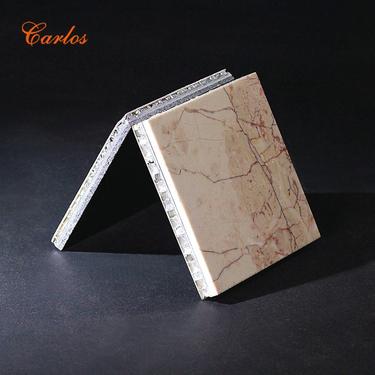

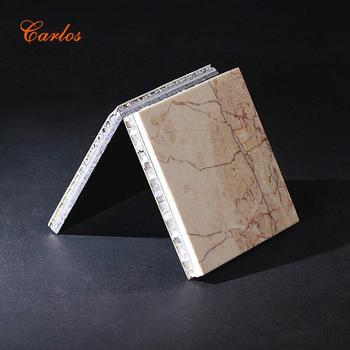

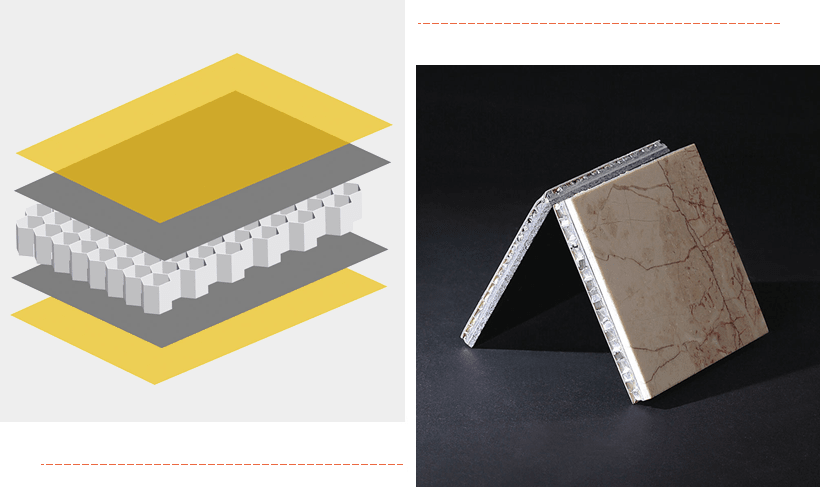

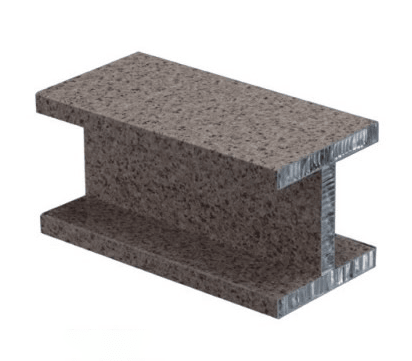

Aluminum Honeycomb plate structure

Aluminum honeycomb panels using composite honeycomb structure, hot-pressed composite molding from the front and back panels of the box-shaped preforms with aluminum honeycomb core . Selection of high-quality 3003H24 aluminum alloy 5052AH14 of high manganese alloy aluminum as base material; panel thickness of 0.5 ~ 1.5mm fluorocarbon roll coating board, floor thickness of 0.5 ~ 1.0mm;core material using aluminum hexagonal 3003 aluminum honeycomb core material, thickness of the aluminum foil 0.04 ~ 0.06 mm, side length of 5 ~ 6mm.

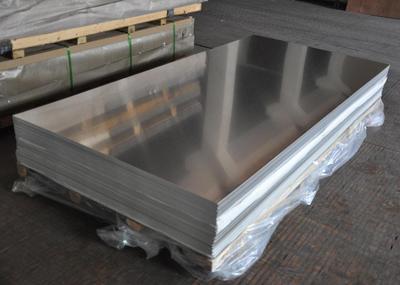

Aluminum honeycomb surface coating

Pre-roll coating:Curtain wall aluminum honeycomb panel surface coating is a one-time completion of the pre-coated fluorocarbon polymer coatings, aluminum panels can effectively control the surface paint color and flatness, the successful elimination of the traditional spray process particles rough problems, uniform color and delicate, soft and beautiful. The main component of fluorocarbon polymer coating contains not less than 70% of Kynar S00 or Hylar 5000 fluorocarbon resin, which is the most stable durable molecular structure with the combination of paint and gas-carbon coating products, it can resist ultraviolet rays in the sun, industrial waste gas, acid rain and chemical erosion for a long time, keep the color stable and smooth for a long time,not cracked, not powder and so on.

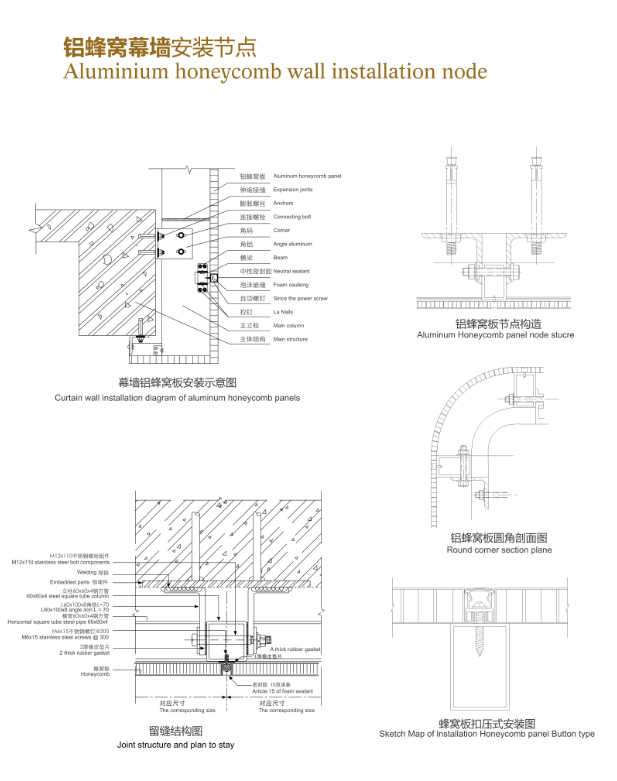

Honeycomb board details and installation drawings

| Technologic Function Of Aluminum Honeycomb Planking Target | |||

Thickness | 20 | 25mm | |

Front aI-planking | 1.00mm | ||

Back aI-planking | 1.00mm | ||

Weight(kg/m²) | 7.4 | 7.8 | |

Mechanics function of complex planking and surface planking | |||

Incrtia rectangle 1(cm⁴/m) | 19.85 | 31.67 | |

Measurement of cuting W(cm³/m) | 19 | 24 | |

Hardness of compiex planking E.I(KN CM²/m) | 139000 | 2217000 | |

Aluminum profile surtace planking | AA 5754A(ALMg3) | ||

Changeable measurement (N/mm²) | 70000 | ||

Pul-pectecting strenght of surface planking(N/mm²) | Rm≥220 | ||

0.2%power of bencing (N/mm²) | Rp0.2≥130 | ||

Extanding rate (EN485-2:1994) | A50≥8 | ||

Hot expanding of aluminum materials | 2.4mm/m 100℃ | when the | |

Surface decoration layer | Pvdf spray and bake pant | ||

Luminsity (original data) | 30-40% | ||

Hardness of pencil | HB-F | ||

Honeycomb core | |||

Size of honeycomb | 1/4(6.3mm) | ||

Weight standing of aluminum mateials | it is about 80kg/m³ | ||

Strenght of pressure-reslstabt(MIL-STD-401) | 4 N/mm | ||

Function of acoustics | |||

Data of sound sucking As | 0.05 | ||

Indicatcr od sound aepaeating According to iso707-rw | 23 | 25 | |

Function od heating | |||

Data of heating guiding λ (w/m²k) | 2.25 | 2.7 | |

Data of heating preverting R (1/m)(m²k/w) | 0.0089 | 0.0093 | |

Data of heating passing U(K)(wmk²) | 5.59 | 5.575 | |

| to complex planking, the data of heat passing "λ" depends on the thickness of planking | |||

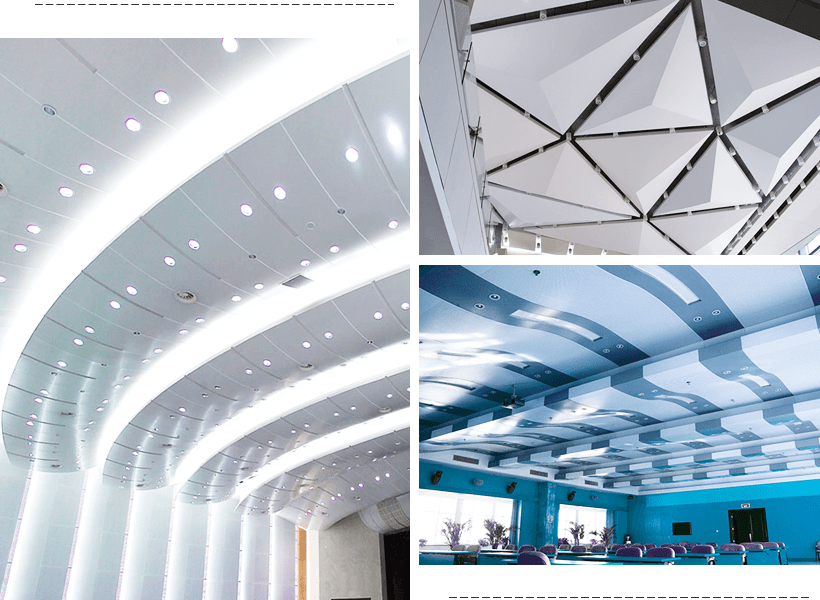

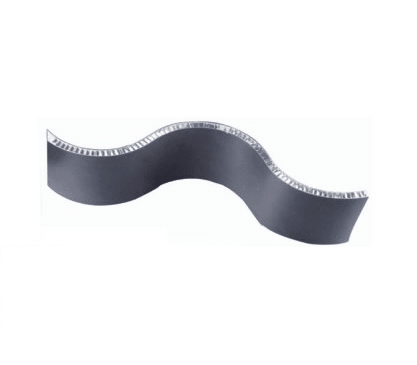

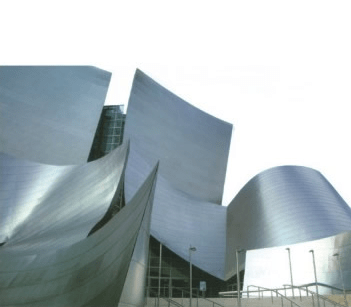

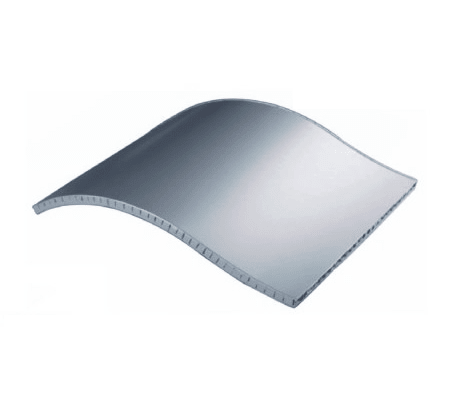

Aluminum honeycomb board opposite ceiling

Heterosexual ceiling products do not use the standard molding die, the product does not have the standard shape and size. Heterosexual ceiling through the use of shears, bending machines, arc bending machines and other equipment to the processing of the panel into the curved plate, nook, trapezoidal plate and other shapes of products. Non-standard board ceiling system break the conventional standard ceiling modeling concept, unique design innovation, modeling imaginative, to meet the special needs of the construction site design needs. Regardless of where it is applied, the simple, atmospheric block, the changing shapes, colorful colors and shimmering texture bring every designer and owner the ideal pride and style of architecture Features. Profiled board ceiling system is specially customized according to customer needs, shaped products, used in some areas of design and function of the special needs of the building.

1、Explanation on the installation node of the product.

2、Explanation on the installation process explained of the product.

3、Explanation on the after-sales problem of the product.

4、Contact us: KLS315@163.com, we will reply to you within 48 hours.

Project Material Shipping Method: Shipping

Contact

Supplier

Balustrades & Handrails

Bathroom

Boards

Building Glass

Ceilings

Countertops,Vanity Tops & Table Tops

Curtain Walls & Accessories

Decorative Films

Door & Window Accessories

Doors & Windows

Faucets, Mixers & Taps

Flooring & Accessories

Formwork

HVAC Systems & Parts

Kitchen

Ladders & Scaffoldings

Masonry Materials

Metal Building Materials

Mosaics

Plastic Building Materials

Quarry Stone & Slabs

Real Estate

Stairs & Stair Parts

Tiles & Accessories

Door, Window & Accessories

Stone