hydraulic Spring loaded Energized PTFE Seal rotary shaft seal/V type

Supplier Info.

Company Name: Dms Seals Technology Co.,limited

Registration Date:

2006

Country / Region:

guangdong / China

City:

foshan

Main Products:

O-ring Seal,Oil Seal Manufacturer

Product Detail

Specifications

| Materials | PTFE,PTFE+Bronze,PTFE+MoS2,PTFE+Glass Fiber,PTFE+Carbon/Graphite,PCTFE/UPE/PEEK |

| Properties | Low friction, Free of stick slip, High abrasion resistance, Wide temperature Range, Good thermal conductivity, Low wear and high extrusion resistance, Wide fluid application range, Resistance against cold flow. |

| Temperature | -40~+316°C |

| Color | brown,green,black,white,blue etc. |

| Size | various |

| Delivery time | 7-15 days by express after payment or 10-20 days by ship |

| Payment | L/C, T/T, Western Union, Money Gram, paypal |

| Shipping | By airplane, ship. |

| Express | Fedex,TNT,UPS,DHL |

| Customized | OEM & ODM are welcomed |

| Application | 1.Mobile Hydraulics.

Air compressor,Excavtors,hydraulic cylinders,pneumatic cylinders,earth moving equipments... |

Product Display

Certificate

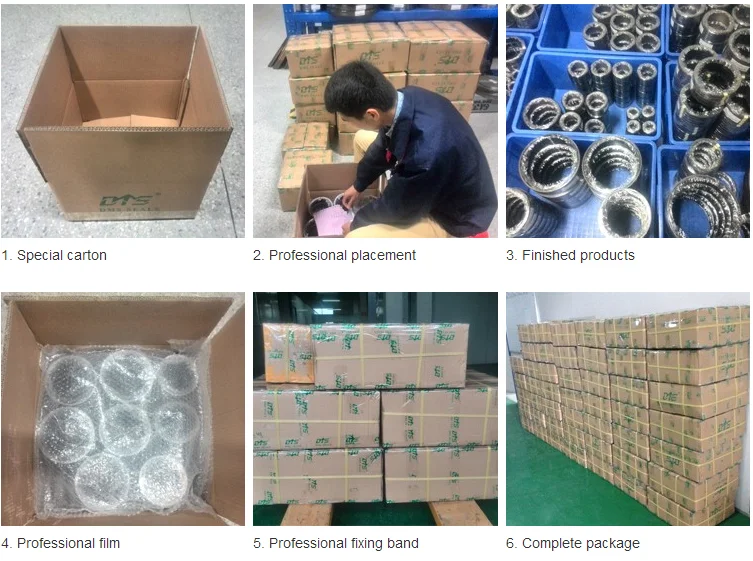

Packaging & Shipping

Company Information

Related Products

With its strong elasticity, the product can be flexibly used in a variety of fields no matter in production or life. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system.

The product can work for up to 20+ years while surviving thousands of recharge cycles and operating across a wide temperature range. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system.

Contact

Supplier

Contact us

Tell us your Buying Requirements

You Might Also Like