1. Single nest is a special algorithm for nesting several single parts at the same time. It's more or less impossible to find this layout in a manual way .

2. Rectangle nest is a special algorithm developed for nesting of rectangular parts (it don't have to be rectangles).

3. Circle nest is another special algorithm developed for nesting of circular parts. (It don't' have to be circles).

4.Automatic nesting are the most flexible nesting tool.

5.Quick nest can be used if you prefer to do the nesting in a manual way.

6.Glide nest is similar to Quick nest but have another user interface.

IGEMS Water Jet CAD CAM

IGEMS is a CAD/CAM software design for Abrasive WaterJet Cutting.Beware of that TEENKING machines support all features described in this document.In the software you can do everything from design of geometry’s,to generate the toolpath and all the steps between.It’s available in many languaged,in metric and imperial measurements.

First thing is the geometry:

To be able to generate a code for the machine to cut something you must have a geometry that describe the final product and the movements in the machine. The geometry must be drawn in exact size and tolerance. In IGEMS the geometry can be generated in many ways:

◪ 1. You can generate the geometry in the powerful CAD-system.

◪ 2.You can import data from other 2D-CAD system.

◪ 3.Select parametric shapes in our library of 53 different shape types.

◪ 4.Unfolding of tubes,IGEMS have many parts for duct mannufacturing,right now without any K-factor.

◪ 5.Make spur gears by the spur gear generator.

◪ 6.If you working with signs then you may will be a winner.

◪ 7.If you have a camera or a scanner.Take a picture and generate the geometry automatically.

◪ 8.The nozzle generator.

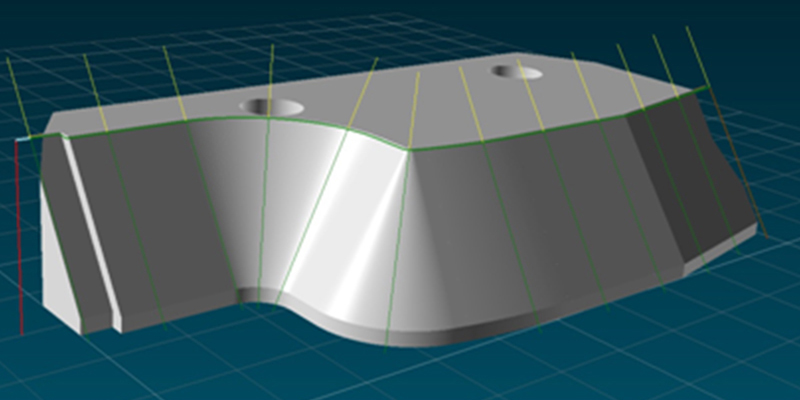

◪ 9.If you have a 5-axis cutting machine,then you need 3D information,In IGEMS you can import this information from a professional 3D systems by using STEP,IGES or STL files format.

◪ 10.Reverse engineering.

◪ 11.IGEMS have an inbuilt application language this can be used for generating geometries from various thing.

◪ As we know VOC is a very strong support for the vertical compensation for different thickness and quality cut,I wonder if IGEMS already count the VOC also by bigger degree cut?Example I want to cut with 30 degrees,as you know if only consider 30 degrees,it is not precisely,we must put VOC as well to compensate the un-vertical cut by the jet.

A part is a group of objects(for example:lines,arcs, circles)that describe the geometry profile.The part have also information about the quantity of parts to produce,and some other properties,To creat parts from geometries is very simple.

The most important property in the part is the cutting quality.It can be up to 400 percent difference in speed between the most rough and most fine quality.Do never use a better quality than the requirements.The initial cutting quality is set when you define the part,but you can easily change the quality by using the quality command.

Third thing is the nesting:

The nesting is only needed if you should cut several parts. The nesting is about to use as less material as possible by placing the parts in a clever way on the material. In IGEMS we have six different nesting commands, made for saving material. The most of them are using the quantity properties stored in the part to nest the correct numbers. Here comes some example:

First thing is the geometry:

A part is a group of objects(for example:lines,arcs, circles)that describe the geometry profile.The part have also information about the quantity of parts to produce,and some other properties,To creat parts from geometries is very simple.

The most important property in the part is the cutting quality. There are several ways to add the toolpath to the parts.

◪ 1.When using the option single,you need one click with the mouse for each geometry to cut.Use this option when you need to control the exact start position.

◪ 2.The most automatic way is to use the option Multiple.

◪ 3.If you want to cut only some side of a part or a slit inside a part then you can use the command Quick.

◪ 4.By using the command marking you can easily add infromation to various king of marking devises.

◪ 5.If your machine is equipped with a drilling unit,then this can be used for making start holes in material,but it can be used to drill holed that not should be used for cutting.

◪ 6.If the parts have long straight sides then you can save a lots of time by using Common Cut lines.IGEMS support two methods of common cutline.

Final stage,creat the CNC-file:

When you have all the parts located on cleaver locations on the sheet and the toolpath is added then just press the process button and select the parts. All the information are collected and processed, with this you can do several things:

1. Create the CNC-file is the most used option.

2. The same information can also be used to make estimations for cutting cost and material cost. This is very important function in the sales stages .

3. You can make reports. The reports can be generated in Word or PDF format.

4. You can also use the information for simulations. Two different types of simulations is possible 2D and 3D.D

5-Axis Cutting:

The 5-axis cutting machine can be used for two major purposes. To obtain a straight cut onnormal 2D parts or to make a cut in a special angle on 2D or 3D parts.

Taper control

When you are cutting with a fast speed the edge of the part become more conical compare with cutting with a slower speed.The angle will be laeger in thin hard material then in soft thick material.IGEMS can automatically adjust the nozzle tilt for actual speed so the the final result will be a straight angle.

1.Some machines need longer time to cut with taper control than without.Of this reason we have a command to turn the TAC On/Off for each geometry on the part.In this case use only TAC on that geometries that are needed.

Chamfering for welding

A lot of parts are produced that later should be welded together.Of this reason IGEMS have developed an easy way to make this king of chamfers.We call this command Quick Bevel.Chamfering with different angles,you can make more complicated 5-axis part by using the standard bevel command.In this case we first define the bevel and then cut the bevel.

Ruled Bevel

You can define a complicated part from two geometry’s with this option.One geometry specify upper profile and the other specify lower profile.

3D to 5X

It is also possible to load a STEP,IGS or STL file made in a 3D-system and add the toolpath in 3D.

Special about Z handling on 5-axis cutting

When cutting with a straight vertical jet the exact Z-position of the nozzle is not that important as it is when cutting with a tilted nozzle. IGEMS have a method called measuring in advance. This method can be used if your machine have a laser or some other measurement tool that can be used on non-flat surfaces. The method only measure a few points on the surface and do an interpolation between this points in the CNC-controller during the cutting. The Z-coordinate are interpolated from the measurements, all other information are generated in the postprocessor.

Cutting in stone and ceramics:

We have covered the most general part of the software ,and we will take a look at some special areas of waterjet cutting now. The first we will cover is the stone cutting.

Tile cutting

IGEMS have a special command for cutting tiles.

If you have a pattern of the inlay, then you can create the production information on a couple of minutes .

Special handling of the piercing

The most kind of stone material need a special handling of the piercing (the start hole). It is a risk that the material get dammed specially on the bottom side. If you cut in glass then the class easily can get broken. If this case IGEMS can make all the start holes in a much lower pressure. To speed up the process all start holes can be done as a special stage before the real cutting start.

Tube cutting

IGEMS support tube cutting on tubes in optional convex profiles. In this example will show cutting on a rectangular tube.

Camera

IGEMS have a camera function that have an advance scaling function. By mounting the camera above the machine. You can import a scaled image of the actual table layout. You can place the parts on the image. You never have to search for zero points, it will make the job very easy for the operator when using rest sheets.

Contact

Supplier