IRB 1600ID -Automatic Welding Robot Arm for Machine Tending

| Specification | |||

| Variants | Reach | Payload | Armload |

| IRB 1660ID-6/1.55 | 1.55 m | 6 kg | 15 + 15 kg |

| IRB 1660ID-4/1.55 | 1.55 m | 4 kg | 15 + 15 kg |

| Number of axes | 6 | ||

| Protection | IP40 (wrist IP67) | ||

| Mounting | Floor, tilted, wall and inverted | ||

| IRC5 controller variants | Single cabinet, Panel mounted,Compact controller | ||

| Physical | |||

| Robot base size | 484 x 648 mm | ||

| Robot height | 1392 mm | ||

| Robot weight | 260 kg | ||

| Performance | |||

| Position repeatability (RP) | 0.02 mm | ||

| Path repeatability (RT) | 0.05 mm | ||

| TCP re-orientation accuracy, average | 0.30 mm* | ||

| Movement | |||

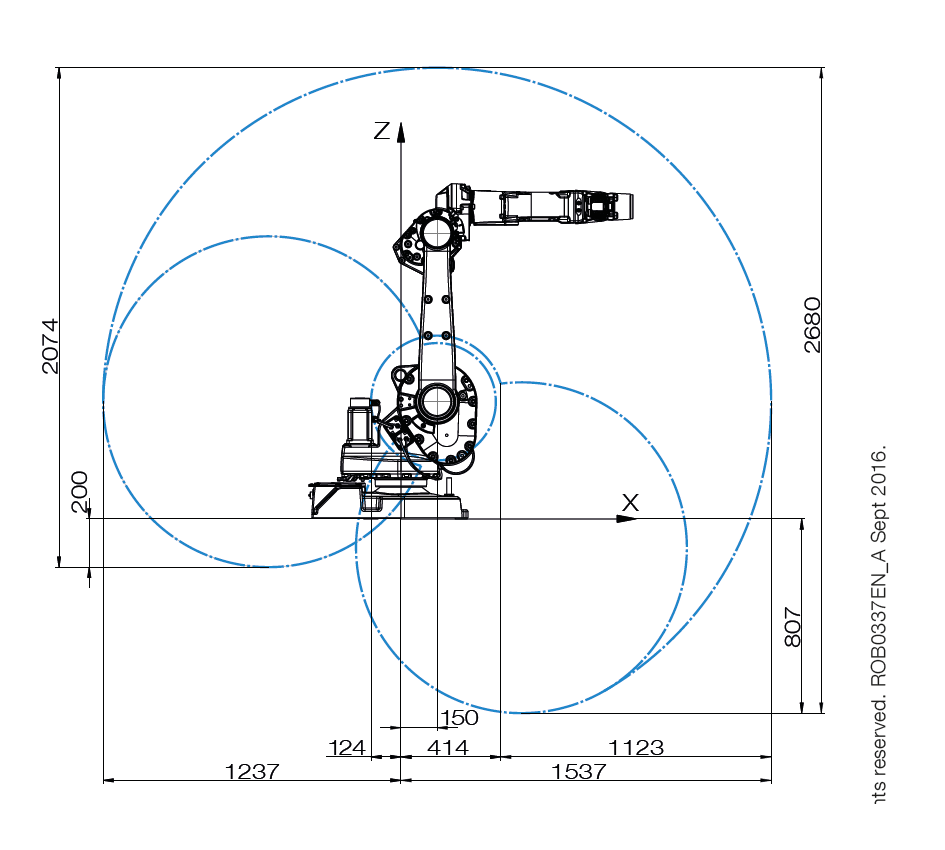

| Axis movement | Working range | Maximum speed | |

| Axis 1 Rotation | +180° to - 180° | 180°/s | |

| Axis 2 Arm | +150° to - 90° | 180°/s | |

| Axis 3 Arm | + 79° to - 238° | 180°/s | |

| Axis 4 Wrist | +175° to - 175° | 320°/s | |

| Axis 5 Bend | +120° to - 120° | 360°/s | |

| Axis 6 Turn | +400° to - 400° | 500°/s | |

| Electrical Connections | |||

| Supply voltage | 200-600 V, 50-60 Hz | ||

| Power consumption | 0,6 kW, ISO-Cube at max load and speed | ||

| Environment | |||

| Ambient temperature for mechanical unit | |||

| During operation | + 5°C (41°F) to + 45°C (113°F) | ||

| During transportation and storage | - 25°C (- 13°F) to + 55°C (131°F) | ||

| For short periods (max 24h) | up to + 70°C (158°F) | ||

| Relative humidity | Max. 95% | ||

| Noise level | < 70 dB (A) | ||

| Safety | Double circuits with supervisions,emergency stops and safety functions, 3-position enable device | ||

| Emission | EMC/EMI shielded | ||

Note

We reserve the right to make technical changes or modify the contents of this

document without prior notice. With regard to purchase orders, the agreed particulars

shall prevail. ABB does not accept any responsibility whatsoever for potential errors

or possible lack of information in this document.

We reserve all rights in this document and in the subject matter and illustrations

contained therein. Any reproduction, disclosure to third parties or utilization of its

contents - in whole or in parts – is forbidden without prior written consent of ABB.

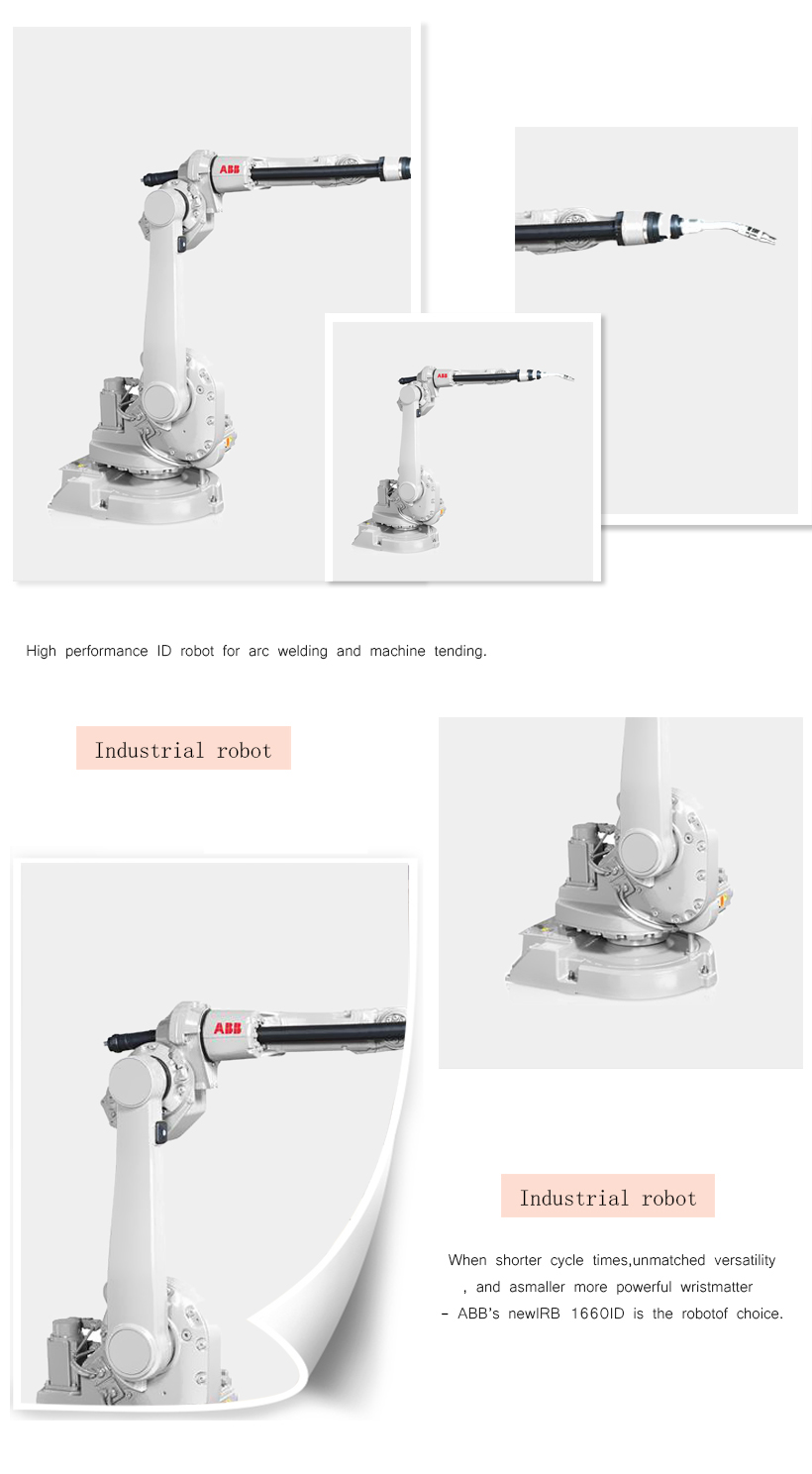

Dedicated arc welding robot

All of the IRB 1600ID's cables and hoses are routed inside the upper arm, making the robot perfectly suitable for Arc Welding. The dress pack carries all the media necessary for arc welding, including power, welding wire, shielding gas and pressurized air.

- Reliable – High production up time

Faulty process cabling is a common cause of unpredicted line stops. With the IRB1600ID, stops can be reduced to a minimum. Because the cables are routed inside the upper arm, their motion is predicted given a certain cycle. When the motion is predicted, so is the lifetime.

- Fast – Short cycle times

Faster then any competing robot in its class.

- Accurate – Consistent part quality

There is always a blind spot when programming a conventional robot. Because of the external routing of the dress pack and its unpredictable motion, programmers have to use their imagination to ensure the dress pack won’t hit anything during operation.

Outstanding position repeatability (+- 0.05 mm) and very good path accuracy.

- Strong – Maximized utilization

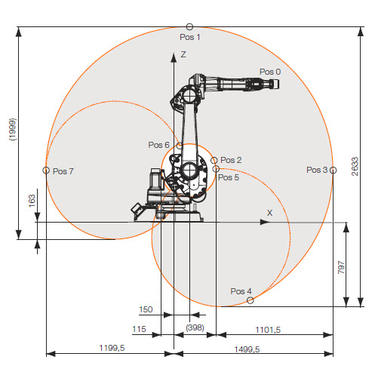

Payload is 4 kg and maximum reach 1.5 m.

- Versatile – Increased accessability

Integrated dressing makes the robot’s outer dimensions smaller. This extends the robot system’s real working range, a crucial factor when welding on fixtures with a complex geometry. It also eliminates the risk of damaging the dress pack in case of collision with the fixture.

Bending backwards concept and different mounting options (floor, inverted and tilted +- 30o of robot base).

High performance ID robot for arc welding and machine tending.

[A smaller more powerful wrist matter - ABB’s new IRB 1660ID is the robot of choice.]

Up to 10% shorter cycle times

IRB 1660ID’s new compact wrist with very powerful motors enables fast and reliable movements that do not impede swinging cables and allow maximum acceleration and speed at all times. This combined with ABB’s QuickMoveTM technology allows the IRB 1660ID to shorten cycle times up to 10% compared to competition.

Outstanding weld quality

The demand for superior and even quality in arc welding applications has increased, requiring improved wire feeding control near the arc to guarantee high volume production.The IRB 1660ID has a stronger more rigid upper arm able to lift up to 6 kg to accommodate heavier torches. This, combined with ABB‘s TrueMoveTM technology and the new motion process “Accuracy mode” provides 0.05 mm path repeatability for excellent welding results.

Safe robot movements enable high density cells

The IRB 1660ID with the aid of RobotStudio®, ABB’s premieroffline robot software programming tool, enables robot programmers to envision high density cells with several robots welding close to each other with a minimum of workpiece heat distortions. RobotStudio simulations help to secure safe robot movements with max speed and accelerations at all times to provide predictable and shortest possible cycle times. Such high density cells can maximize your output, provide top quality parts and operate with unmatched reliability.

Fast, agile and reliable for machine tending

The compact and hollow wrist enables fast and reliable movements since the robot can move at maximum acceleration and speed without damaging the Integrated DressPack. The risk of collision in confined spaces is also eliminated. The combined working range of axes 4, 5 and 6 of 1,390° provides outstanding agility inside CNC machines. The IP67 wrist, the protection of the cablings from water and the controlledmovements provide up to 50 percent lower maintenance costs and a longer life expectancy.

Simplified online programming

Online programming is further simplified thanks to the full control of the hose packages or cablings, the compact 135 mm size wrist for faster re-orientations and the 0.30 mm reorientation accuracy (absolute accuracy option needed) for highly accurate corner re-orientations.

Main applications

− Arc welding

− Machine tending

− Material handling

Contact

Supplier