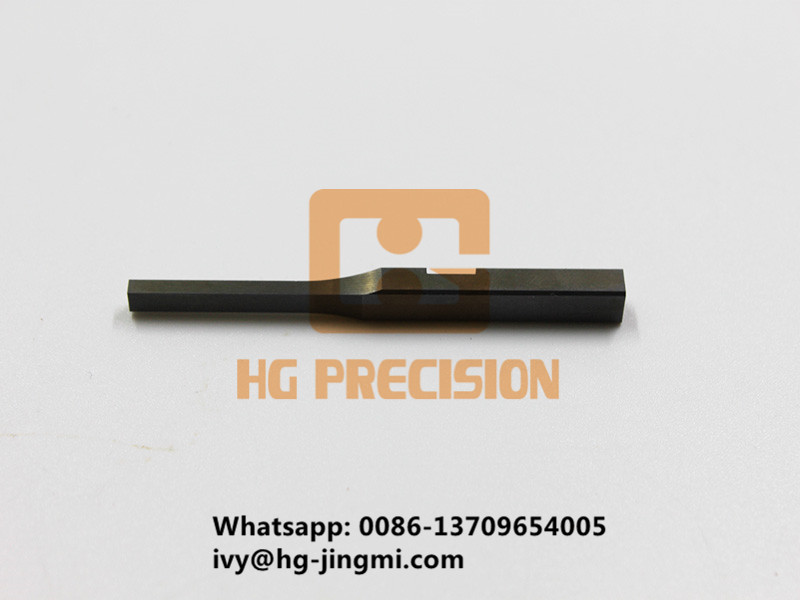

K20 Carbide Punch With Ticn-HG Precision

K20 Carbide Punch With Ticn

The increased tool life from using coatings varies. Primarily, coatings extends lubricity to the sides of the punch reducing galling. Further, coatings create a harder surface which extends hits between sharpening. Extended life will be directly related to the rigidity and alignment of the press and the material type and thickness being punched.

On a rigid press punching 16 gauge mild steel, we believe TiN (Gold) may extend 3-6 times more hits before the first sharpening. TiCN (Grey) may extend 5-10 times more hits before the first sharpening. After the first sharpening, the extended life between sharpenings probably cuts in half. The argument against coatings is that there may be a better value in simply utilizing punches with higher quality substrates like High Speed Steel and place more attention to continued lubrication of the moving components of the tool.

A High Speed Punch will in general outperform say a D2, A2 or A8 punch coated with TiN (gold) at a much lesser tool cost. On the other hand, although having an initial higher cost, the TiCN coated D2,A2 or A8 punch in ideal conditions may out perform the un-coated High Speed Steel tool.

Which coatings to use?

TiN is good in applications like punching soft material such as an aluminum. Your concerns here will be the adhering (galling) of the material to the sides of the tool placing wear on the punch tip and greatly increases required stripping force.

TiCN seems best suited for harder materials as it is a harder coating and adheres (meshes) to the steel better than TiN. There is less tendency for this TiCN to chip or flake

Contact

Supplier