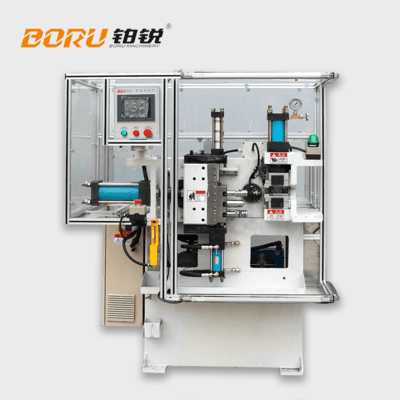

KDW-216-2X2 pipe nonchip cutting machine

● The chip cutting machine has the advantages of beautiful appearance, no CNC double double reasonable structure, stable operation, convenient conversion specification, the pipe necking rate is small, and the work efficiency is high. The 4 reel material tube can be in this machine, the active or passive feeding, school circle, straightening, fixed length feeding, no dust cutting, cutting pre tension, the final break, aggregate process, in addition to artificial plate and artificial material outside the fixed length cutting work.

● This machine is composed of three parts, which are main machine (straightening, feeding, cutting), discharging rack and receiving rack

● This machine has the functions including: plate material straightening, feeding, clamping, chipless cutting, residual tensile, automatic counting, enough shutdown without alarm alarm, shutdown, automatic blanking and so on.

● The machine can be opened at the same time two different lengths, different diameter pipe material, each batch of 2 tons of raw materials, according to the set automatically completed

project | Technical parameters and specifications | Note appended | |

Processing materials | Texture of material | copper pipe | |

| Outer diameter and wall thickness of pipe | φ6~φ16 | ||

Processing capacity | Primary opening number | 4: φ (diameter) × 2 + φ (diameter) × 2 | Two groups of materials of different lengths and diameters can be cut at the same time |

| Single feed stroke | 1000 mm | ||

Cutting length | 70~3000mm | <120mm material length, no pre drawing process, necking rate is also explained | |

production efficiency | The number of times of opening per minute is greater than 9 times (L = 500 mm) | ||

Precision | Straightness tolerance | ≤ 2 ‰; 0.5mm / 1000mm; Shrinkage rate ≤ 20% unilateral ≤ 0.15 mm | Do = actual wall thickness |

Surface appearance | The pipe surface has no obvious pulling, pulling, pressing, scoring and knurling scratches, and the pipe head has no burrs | ||

| Power Supply | Three-phase380V | ||

| Gas pressure | 0.5-0.7Mpa | ||

| Equipment cooling mode | Air cooling | ||

Contact

Supplier