Cordierite mullite extruded batts bearing weight increase. For example, ordinary Cordierite mullite plate welght and 23mm 38mm thick extruded batts unit area thick quite, but the extruded batts bearing 5 times the mass of the latter is

Cordierite Mullite extruded batts

The raw material of extruded batts are cordierite and mullite. Cordierite can provide excellent thermal shock resistance. Rapid cooling and heat will not break. Mullite can provide excellent high temperature strength.Our cordierite mullite kiln has a working temperature of 1300℃ and a service life of more than 500 times (2-3 years according to customer feedback).

In addition, there are the following advantages:

1.weight lose of about 35%0-50%

2.the energy saving effect is very obvious.

The use results show that, using extruded batts in the shuttle kiln firing ceramic and glass can reduce the consumption of at least 30% to70%.

3.high temperature is not easy to bend and deform

1200mm long extruded batts With silicon carbide beam support, the use of almost no deformation, absolutely can ensure smoothness of high specification microcrystalline stone

4.the surface of the heat radiating area Is more than 2 times.

so the better thermal shock resistance, long Service life. and can rapidly adapt to the Chi ceramic firing products

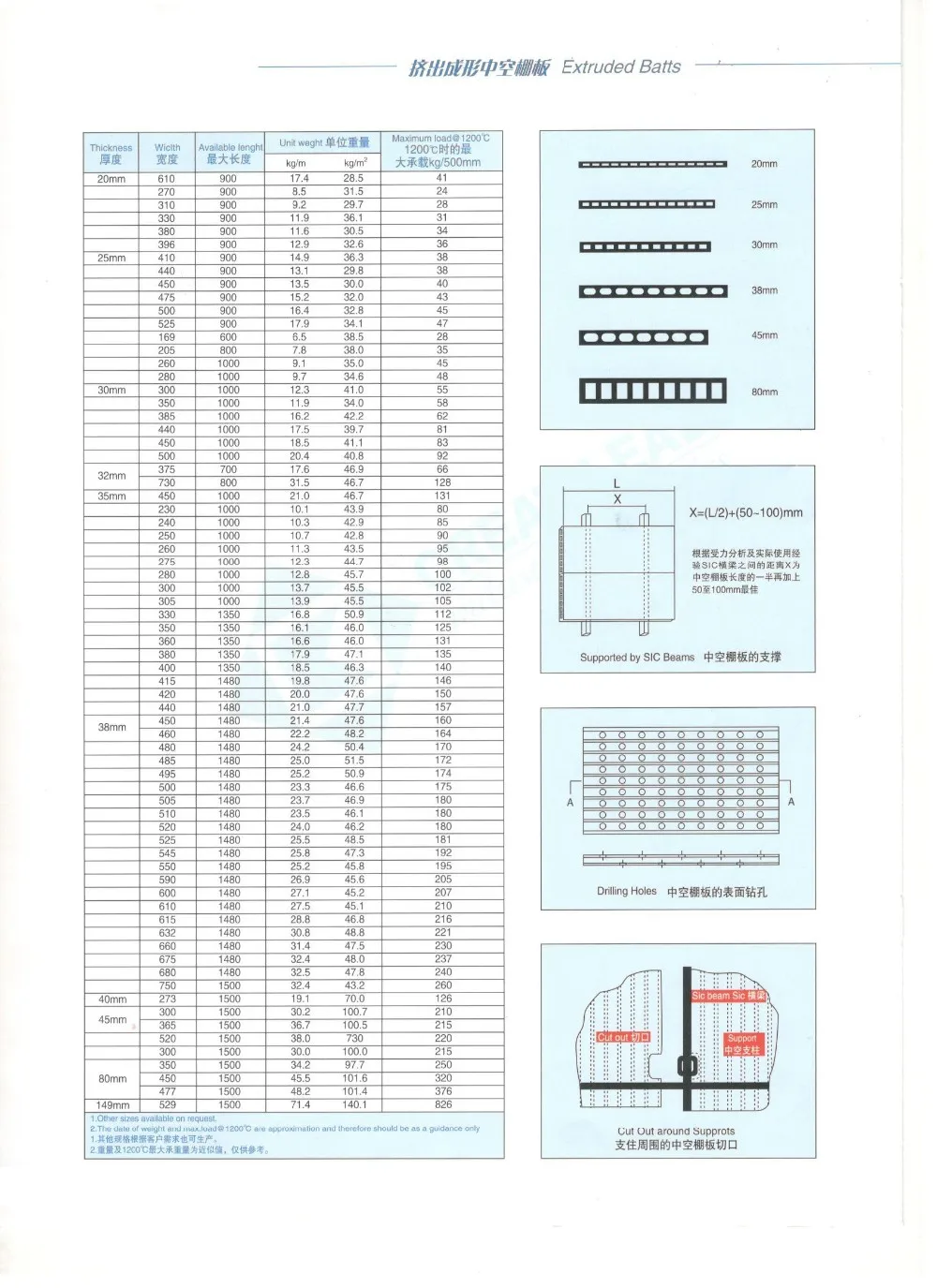

1.Other size available on request. Please contact us for more sizes.

2. The date of weight and max load @ 1200c are approximation and therefore should be as a guidance only.

Properites | Units | Cordierite mullite | |||||||||||||

Mineralogy | C-Cate Gory | R-Cate gory | E-Cate gory | A-Cate gory | T-Cate gory | ||||||||||

Chemical composition | Al2O3 % | 40 | 41 | 36 | 39 | 41 | 43 | 46 | |||||||

SiO2 % | 49 | 48 | 52 | 49 | 47 | 46 | 44 | ||||||||

MgO % | 6.5 | 7.0 | 7.0 | 8.0 | 7.0 | 7.0 | 6.0 | ||||||||

Bulk Desity | g/cm3 | 1.95 | 1.90 | 1.85 | 1.82 | 1.95 | 1.82 | 2.00 | |||||||

Apparent porosity | % | 26 | 28 | 28 | 29 | 26 | 33 | 25 | |||||||

M.O.R.@20℃ | MPa | 14 | 13 | 16 | 10 | 13 | 15 | 18 | |||||||

M.O.R.@1250℃ | MPa | 14 | 13 | 10 | 11 | 15 | 15 | 17 | |||||||

C.T.E.@20℃-1000℃ | 10-6K-1 | 2.3 | 2.3 | 2.6 | 2.2 | 2.2 | 2.5 | 3.1 | |||||||

Specificheat@20℃ | KJ/KG·K | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.1 | |||||||

Thermal shock resistance | ★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★ | |||||||

Max working temperature | ℃ | 1300 | 1250 | 1300 | 1320 | 1280 | 1280 | 1350 | |||||||

application | Used in ceramic shuttle kiln, tunnel kiln and roller kiln,Kiln furniture. | ||||||||||||||

Package details

1.50 pieces in a wooden box (fully enclosed, safe and secure)

2.800kg~1000kg /wooden box.

3.Anti-collision protection such as foam board

4.3-layer wood composite panel, sturdy, impact resistant, drop resistant

Shipping details

1.Professional car transport to various ports in China, then loaded by a professional shipping company.

2.Both FOB and CIF can be operated flexibly.

3. Competitive sea freight and short transit time

Sanitary ware industry application

Industrial electric ceramics

Placement of extruded batts

Placement of extruded batts

Matching pillars and slabs

Prop pillar

splicer

Air Barrier hanger

Collar

Small pillars

Henan Lite Refractory Material Co., Ltd is a high-tech company specializing in the production of cordierite mullite Material.Founded in 2002, the company covers an area of 40,000 square meters.With refractory research and development department (become zhengzhou university doctoral research site), production department, sales department, drawing design department.It is an advanced cordierite mullite kiln manufacturing company with an annual output of 5000 tons.

Our equipment and technology imported from Europe, our production process and quality standards are completely in line with European standards.At present, the company has 3 sets of high-pressure vacuum extrusion systems, and 4 shuttle-type kiln with 20 meters cubed automatic 1450℃.

OUR Products are mainly exported to India, Germany, Australia, Vietnam, South Korea, Japan, Britain, Iran, Spain and other countries.

Henan Lite Refractory Material Co., Ltd obtained the ISO9001:2000 international quality management system certification and ISO 14001:2004 environmental management system in 2008.Is a production, research and development, export, sales as one of the comprehensive company

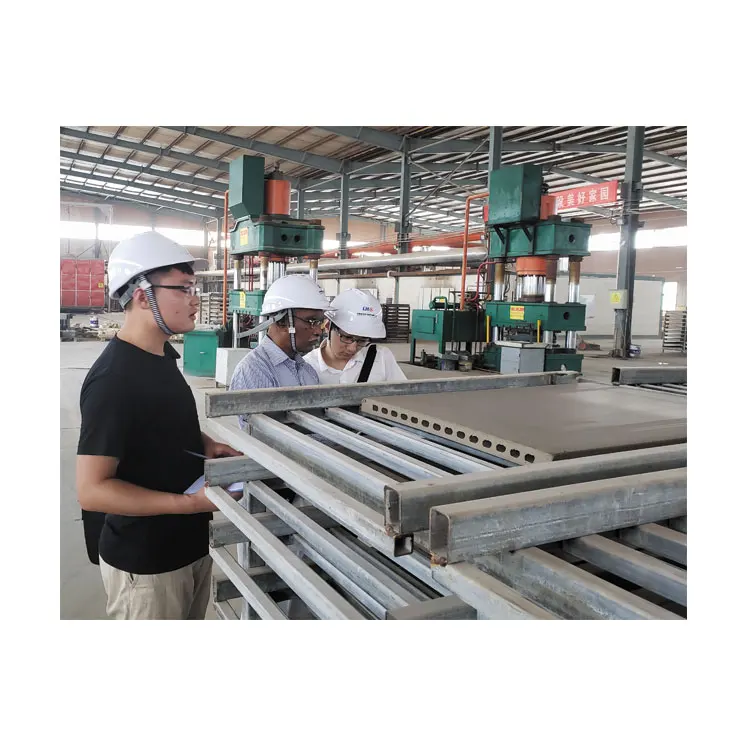

A factory in India to visit and learn our technology

Marvel at the quality and precision of our products

Want to be our distributor

Contact

Supplier