The full cover is called straight bending and straight arms.

KT-165° Clip-on special angle hydraulic hinge

No matter how your door overlay are,AOSITE hinges series always can provides reasonable solutions for each application.

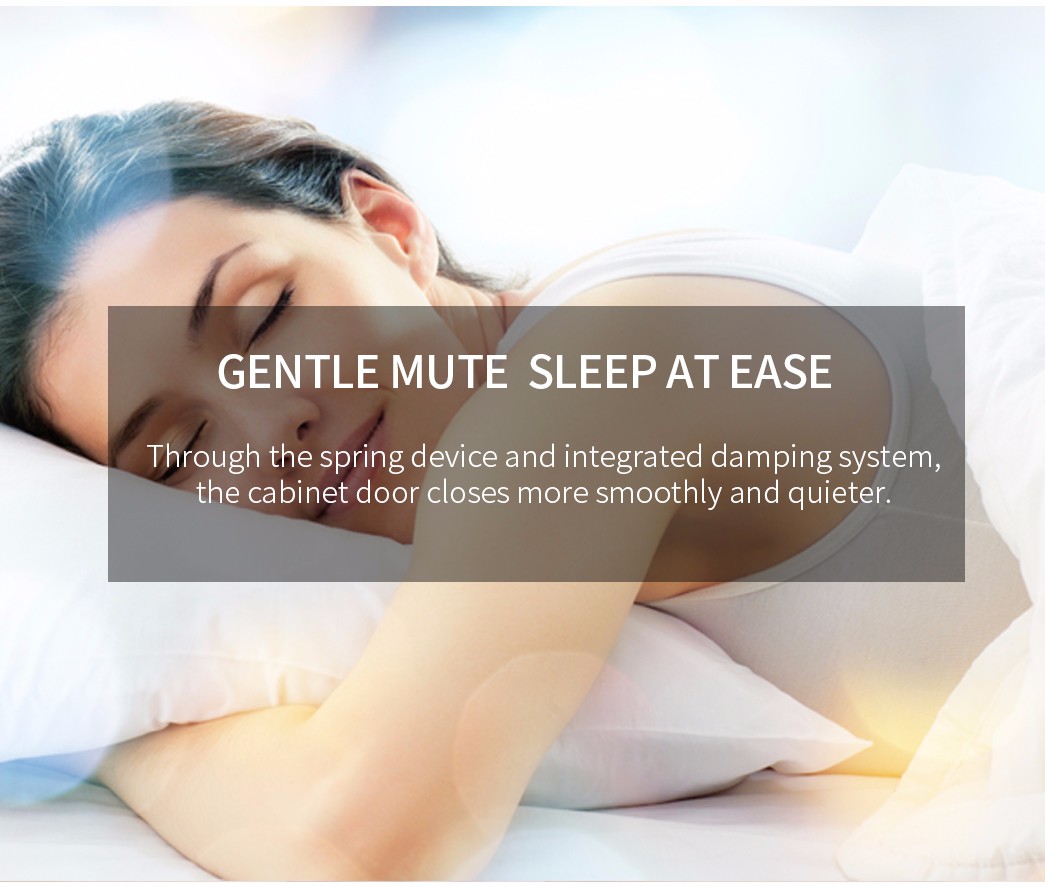

Model KT165,we call clip on special angle hydraulic damping hinge .This hinge with ii’s special fecture,can open angle up to 165 degree,wchich also is hydraulic damping hinge having the soft close mechanism integrated in the hinge cup.Our standars Includes hinges, two holes mounting plates,.Screws and decorative cover caps are sold separately.

0-10db

Sound wave passing through

20db

Hinged sound

30db

Whispering

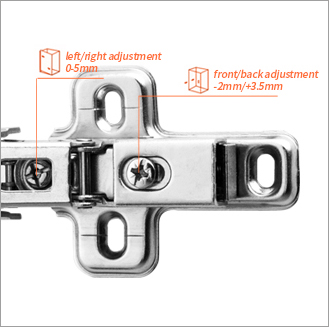

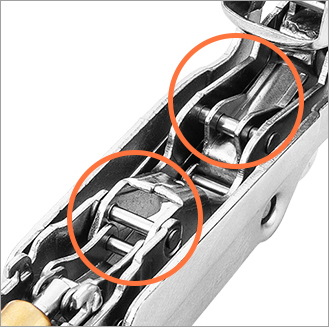

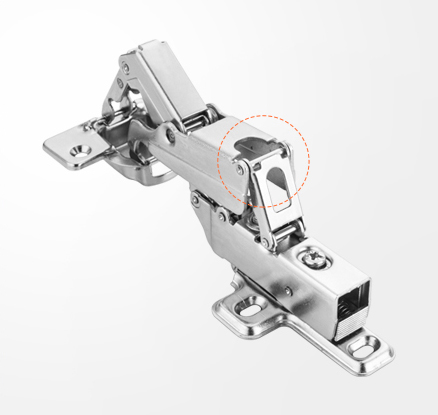

TWO-DIMENSIONAL SCREW

The adjustable screw is used for distance adjustment, so that both sides of the cabinet door are more suitable.

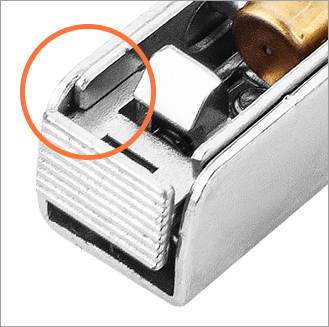

CLIP-ON HINGE

Pressing the button can remove,avoiding damage the cabinet door by multiple installation and remove.

EXTRA THICK STEEL SHEET

The thickness of hinge from us is double than current marke,which can strengthen the servivelife of hinge

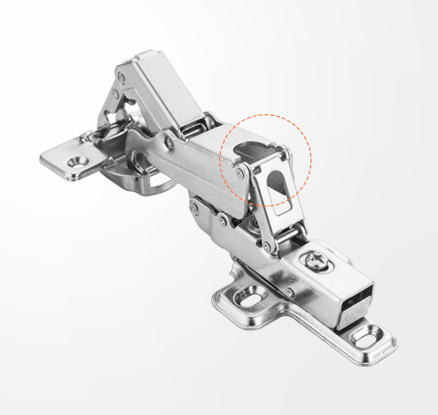

HYDRAULIC CYLINDER

Hydraulic buffer makes a better effect of a quiet enviornment.

STRONG BOOSTER ARM

Increasing buffer pressure of the hige,use well.

PRODUCTION DATE

High quality promision,rejection any quanlity problems.

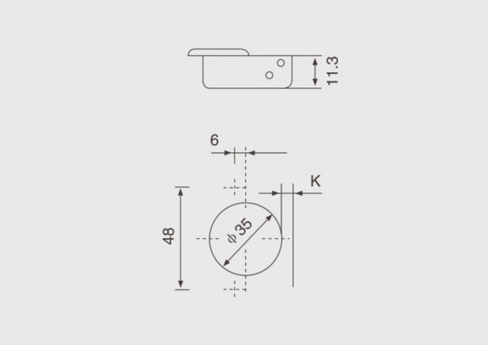

Model:KT-165A

Full overlay

Model:KT-165B

Half overlay

Model:KT-165C

Embed

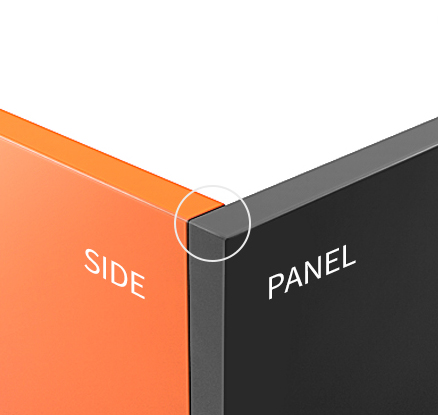

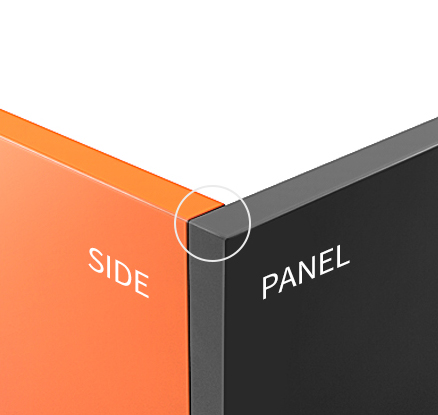

The cover is suitable for the cabinet body ,

which covers the side panels.

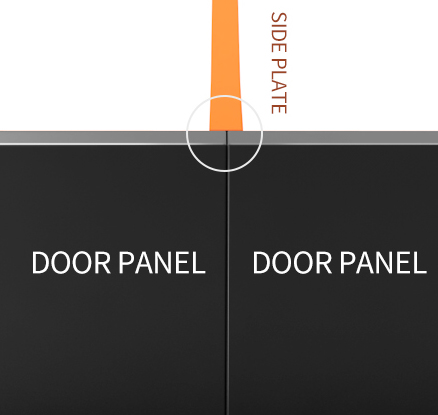

Half cover is also called middle bend and small arm.

The cupboard door covers the side plate,

half of which has doors on both sides of the cabinet.

The door is not covered by the cabinet door,

and the cabinet door is inside the cabinet.

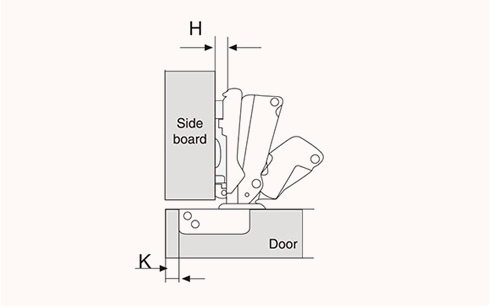

Full Overlay

This is the most common construction technique for cabinet doors.

You will be able to identify if your hinge is Full Overlay:

The Hinge Arm is relatively straight with no "hump" or "crank"

The Cabinet Door overlaps close to 100% on the cabinet side panel

The Cabinet Door does not share a side panel with any other cabinet door

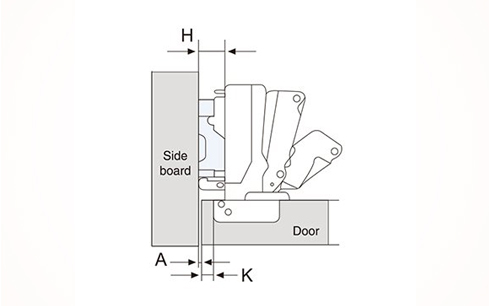

H=15+K-D

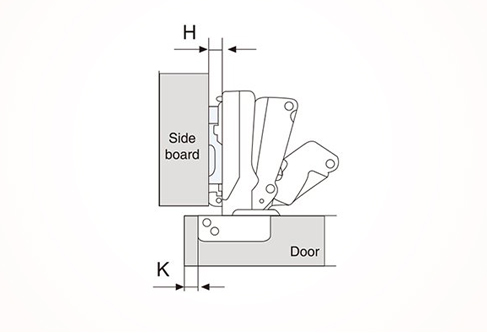

Half Overlay

Much less common but used where space saving or material cost concerns are most important.

This technique uses the same side panel for two cabinets. To achieve this

you would need a hinge that provides these features:

The Hinge Arm starts to bend inwards with a "crank" that offsets the door

The Cabinet Door only overlaps a bit less than 50% of the cabinet side panel

The Cabinet Door does not share a side panel with any other cabinet door

H=5+K-D

Inset/Embed

This is a technique of cabinet door production that allows the door to sit inside the cabinet box.

You will be able to identify that your hinges are Inset if:

The Hinge Arm is quite noticeably bent inwards or highly "cranked"

The Cabinet Door does not overlap with the side panel but sits inside

H=A+K-4

H=Height of mounting plate

D=Required overlay on the side pane

K=Distance between door edge and dritlling holes on

hinge cup

A=Gap between door and side panel

X=Gap between mounting plate and side panel

Refer to the following formula to choose the arm of hinge,if you want to solve the problem,we must kno w “K” value ,that’s the distance drilling holes on the door and “H”value which is the height of mou nting plate.

as

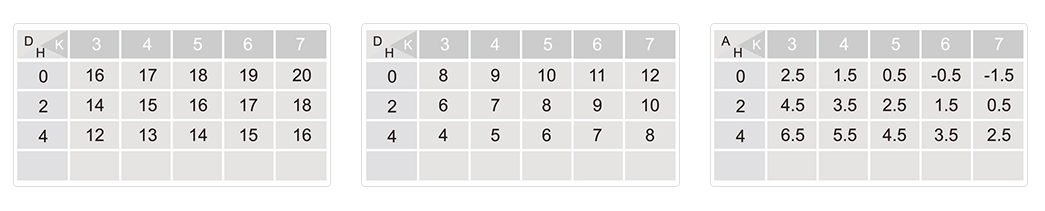

45mm Hole distance

45mm Hole distance is the most common hinge cup pattern for European style

hinges.Almost all of the major Hinge manufacturers selling European

style hinges including Blum, Salice, and Grass are with this hinge cup pattern.

Diameter of the hinge cup or "boss" that inserts into the cabinet door is 35mm.

Distance between screw holes (or dowels) is 45mm.

Center of screws (dowels) is 9.5mm offset from the hinge cup center.

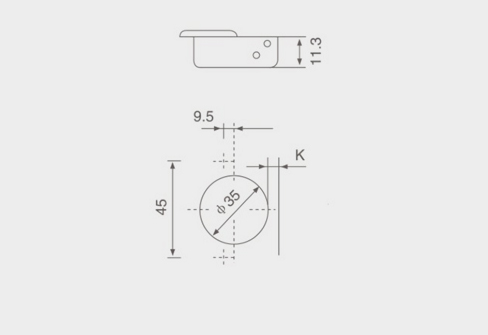

48mm Hole distance

48mm Hole distance is the most common hinge cup pattern used by Chinese (imported) cabinet makers. This is also a common universal standard for other major Hinge manufacturers in areas outside North America, including Blum, Salice, and Grass. These will be very difficult to source as replacements in North America. It is recommended to switch to a more commonly available cup type in that case.Diameter of the hinge cup or "boss" that inserts into the cabinet door is 35mm.Distance between screw holes (or dowels) is 48mm.Center of screws (dowels) is 6mm offset from the hinge cup center.

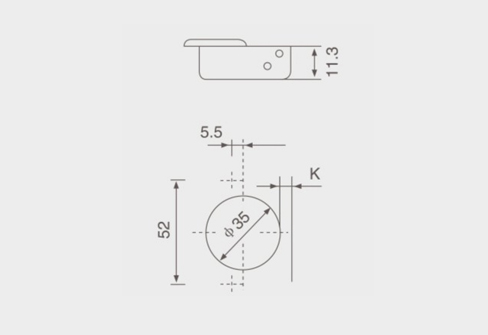

52mm Hole distance

52mm Hole distance is a less common hinge cup pattern used by some cabinet makers,but it’s most popular in Korea market.This pattern is mainly for compatibility with some European hinge brands like Hettich and Mepla. Diameter of the hinge cup or "boss" that inserts into the cabinet door is 35mm.

Distance between screw holes (or dowels) is 52mm.

Center of screws (dowels) is 5.5mm offset from the hinge cup center

M8 dowel

Specification:8x10mm

M10 dowel

Specification:10x10mm

Euro screw

Specification:6.3x14mm

Wood screw

Specification:4x16mm

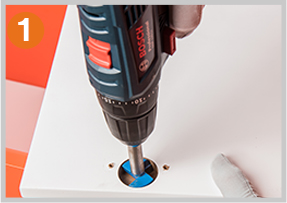

According to the installation data,

drilling at the proper position of door panel.

Install the hinge cup

Aoocrding to the installation data,

mounting base to connect the cabinet door.

Adjust back screw to

adapt door gap

Check opening and closing

Single package Packing in a box

Contact

Supplier