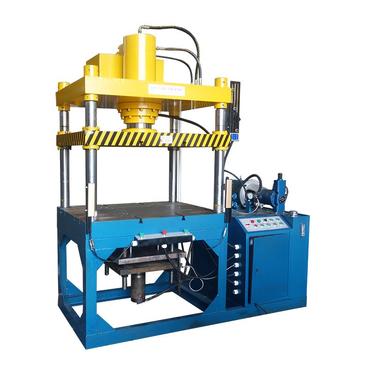

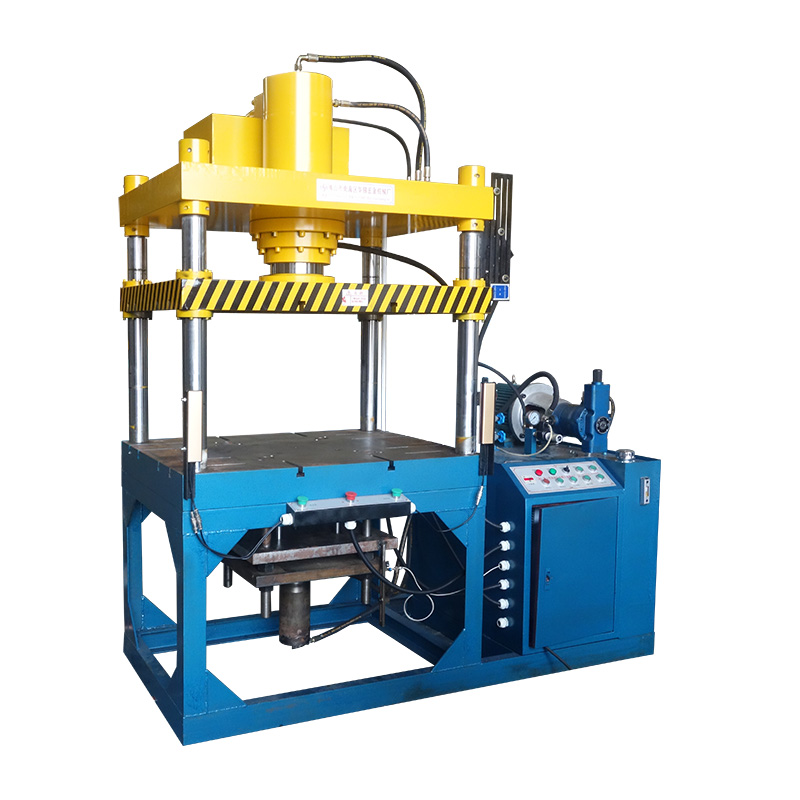

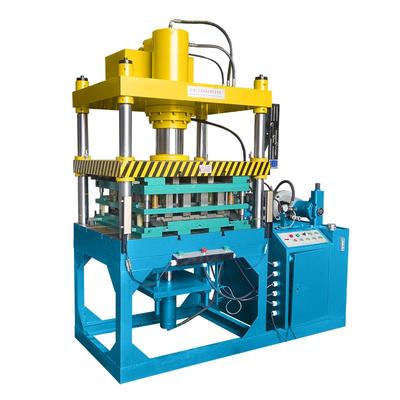

Laminating board production equipment 120T hydraulic machine

Aluminum buckle board production equipment 120T hydraulic machine

Aluminum buckle board production equipment 120T hydraulic machine is mainly aluminum buckle plate (metal ceiling buckle), integrated ceiling panels, engineering ceiling panels, galvanized panels and other metal ceiling materials processing, bending, forming, shallow drawing and other processes Professional processing equipment. Especially the production of 600X600 specifications aluminum gland necessary equipment.

1. Professional custom, rest assured that use

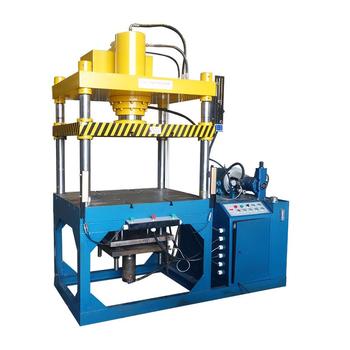

Equipment regardless of length, width, height are based on the market Lvkou Ban (metal) material custom processing, so this device can be used for 600X600, 300X1200, 600X1200, 300X1500 and other specifications of processing, can also be used in the market popular concave convex stamping bending Other processing technology.

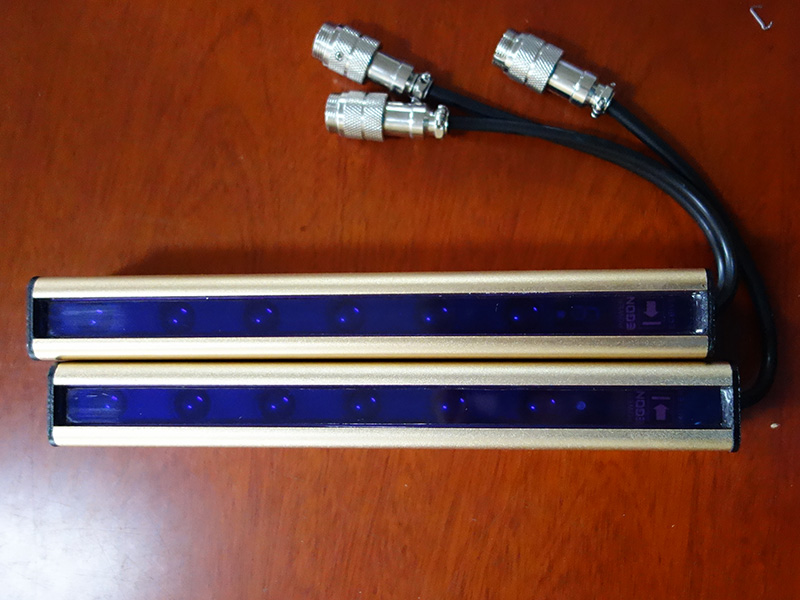

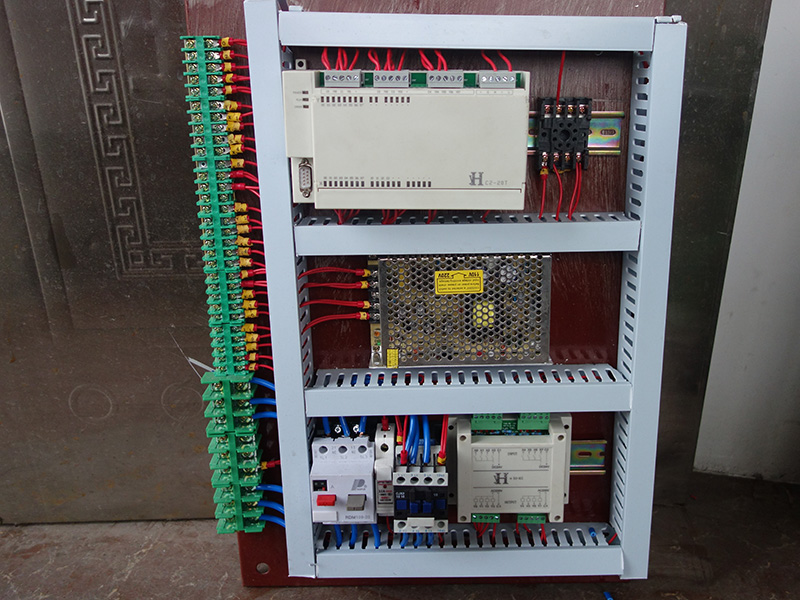

2. High-quality accessories

High-quality accessories, safe and secure Control of raw materials and accessories, a complete package to ensure safe and reliable.

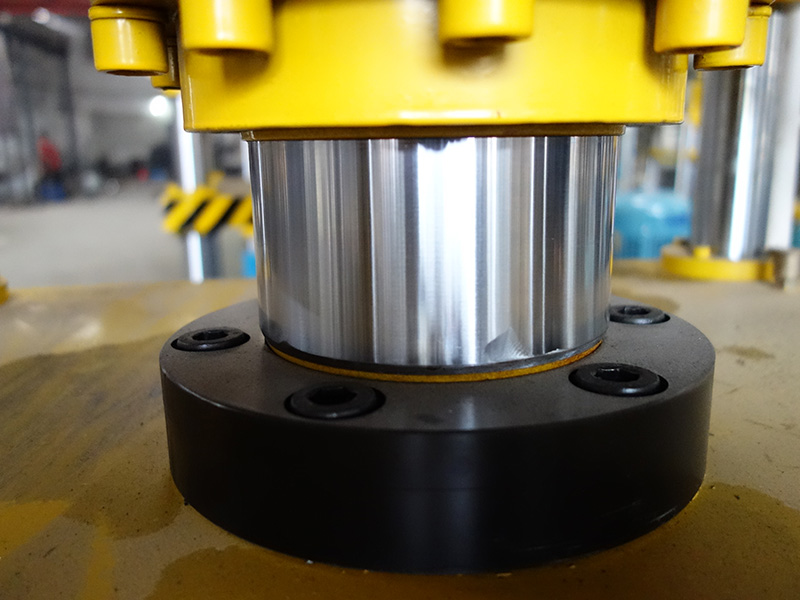

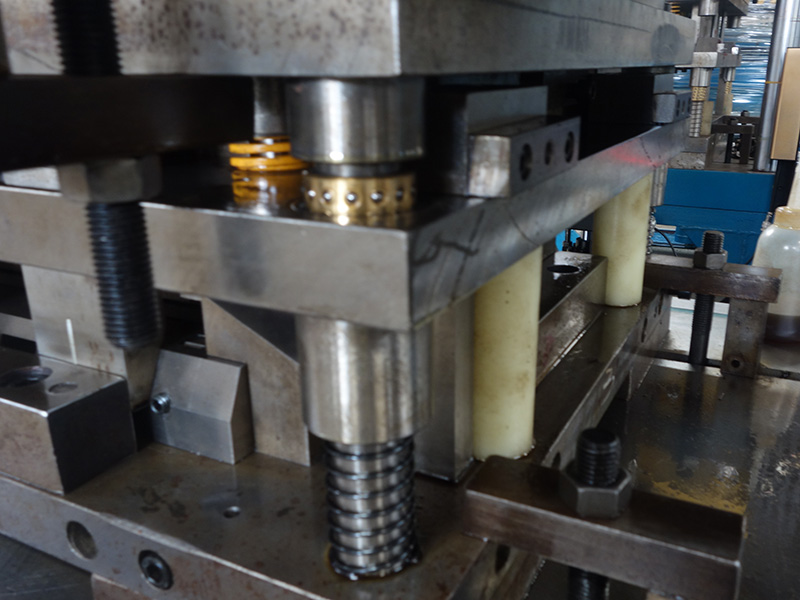

3. Beam board

Beam board using the national standard A3 strength board material, the processing flow: buy back the raw material → flash → milling face → CNC milling → CNC boring → CNC grinding plane → assembly.

4. Equipment support frame, fuel tank

A、 Professional cutting, custom size you need:

Professional steel cutting equipment, your machine every bracket and tank size are professional design professional cutting welding, professional technical assurance of the size of precision.

B、 Welding, using two-oxygen welding:

HuaQiang machinery are used oxygen welding technology, the welding of good quality, good weld cracking, beautiful appearance, small welding deformation, after welding without slag.

C、 Paint treatment, exquisite appearance:

Through the degreasing, rust, table transfer, painting and other processes after treatment.

5. Simple installation, ease of use (home debugging installation, 100% rest assured)

Huaqiang machinery factory is assembled, debugging good. On-site installation is particularly fast, no need to buy other auxiliary equipment such as pump, just put the machine on a horizontal position, the wiring can be directly into the production and processing fuel.

You can also choose to install, save installation costs, Huaqiang has

also been to provide you with professional and technical support.

Technical Project | Work table size | Power | Hydraulic oil | Machine weight | Motor power |

120T large mesa | 1300*900mm | 380V (Three boxes of electricity) | 46 # anti-wear hydraulic oil 300L (Great Wall brand) | 6000KG | 11KW |

60T large mesa | 1100*900 mm | 380V (Three boxes of electricity) | 46 # anti-wear hydraulic oil 300L (Great Wall brand) | 4500KG | 7.5KW |

Contact

Supplier