Super thick heat insulation layer box body + double sealing treatment door, good thermal insulation performance

Laptop, IPad, Mobile Phone LCD Frozen Separator Machine LXPB-880*550

Frozen separator machine

PRODUCT PARAMETERS | |

Product description | Laptop, IPad, Mobile phone LCD Frozen separator machine |

Model | LXPB-880*550 |

Appearance overall size(MM) | 1380*750*945 |

Actual size of frozen(MM) | 880*550 |

Working voltage/frequency | 380V/50HZ, 220V/60HZ |

Power(KW) | 6Kw |

Cooling performance | -160°C |

No-load pre-cooling time | ≤1.5H |

Refrigerant | Environmental mixed refrigerants |

Cooling way | Air cooling |

Environment temperature | ≤25℃ |

Product net weight(kg) | 310Kg |

Place of origin | Shenzhen, Guangdong, China |

Packaging | Standard export wooden case |

Payment terms | PAYPAL or T/T |

Lead time | Within 3 days |

Brand | Li Xiang Refrigeration |

Warranty period | 12 Months |

PRODUCT FEATURES

This machine is a style of medium-sized ultra–low temperature frozen separator machine, independently developed based on the small-sized

ultra–low temperature frozen separator machine according to users’ actual requests. The lowest temperature of the unit can reach up to -160℃

without using liquid Nitrogen as refrigerant. It is widely used to separate out glass, TP, backlight, OCA, LOCA, bracket from various damaged

LCD modules (including mobile phone, laptop, Ipad, TV, etc). It is really a good helper for the LCD screen reparation, rework, refurbishment,

recycling industry. Our machines have the following characteristics:

1.) Separate out glass from the damaged Laptop, IPad, Mobile phone LCD module.

2.) Separate out OCA glue from the damaged Laptop, IPad, Mobile phone LCD module.

3.) Separate out TP from the damaged Laptop, IPad, Mobile phone LCD module.

4.) Separate out backlight for IPhone, for Samsung, for LG, for IPAD Pro, for IPAD 6, etc.

5.) Separate out frame from the damaged Laptop, IPad, Mobile phone LCD module.

6.) No need to change the polarizer film.

7.) Can keep the backlight (be careful, easily damaged), also can take off the backlight.

8.) High efficiency. No components damage during the LCD module separating process.

Operation Instructions

1.) Before using, it will take the machine around 30~40 minutes to cool to the set working temperature.

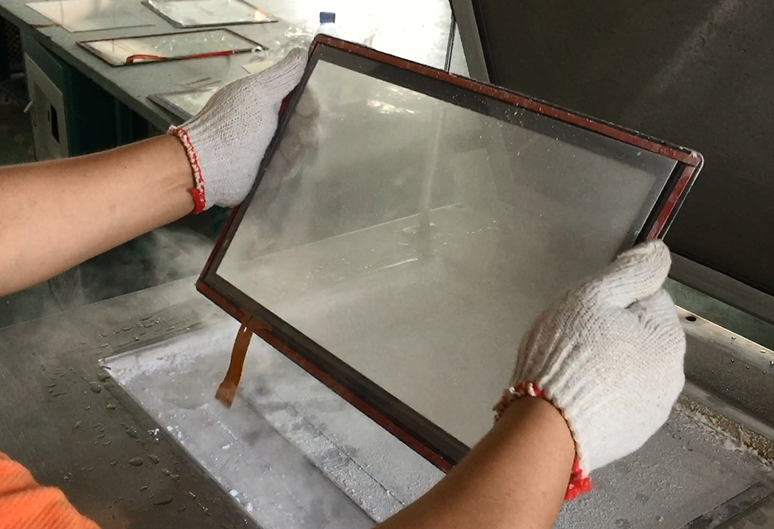

2.) Place the LCD screen on the frozen plate.

3.) Freezing time from 30 seconds to 1 minute depends on different LCD screens.

4.) Take out LCD screen and separate it.

Below is the URL of youtube video link for your reference:

https://www.youtube.com/channel/UCpXgF19dgOMtxk4wz49-yBw

Tips:

1. For serious crushed glass, please stick a tape on glass for safety and good for machine

2. Please make sure the operator wears gloves in case of danger.

3. It is much easier to separate out the bracket and other components after freezing processing. Please pay attention to the backlight water inlet.

4. After separating the LCD screen, pay attention to the water treatment and temperature recovery.

5. When separating the curved screen, the separation risk caused by the temperature difference between 2 sides of the curved surface screen. Please pay more attention to this point.

6. After LCD separation, please put the glue side upward to avoid sticking on the article surface after the temperature return to the normal.

PRODUCT APPLICATION

|

|

Suitable for Photoelectric manufacturer, LCD production enterprises, Mobile phone steel film production enterprises, Mobile maintenance industry.

PRODUCT DETAILS

Imported high precision microcomputer temperature controller, precise temperature control

Imported advanced dual-frequency compressor, more stable refrigeration performance

MAINTENANCE

◆ Do not place heavy objects on the door or cover of cryogenic refrigerator to avoid compression deformation

◆ When receiving the machine, leave it for 2-5 hours before power on and start up. When using, just press the switch after power on

◆ After starting up, the first three minutes are the compression protection time, and the compressor will start after three minutes

◆ Every once in a while, the cryogenic refrigerator should be cleaned and maintained and dust cleaned

CERTIFICATE

Contact

Supplier