1) High efficiency and good surface finish.The machine has 2 cutters: the rough turning cutter and the finish turning cutter, which work synchronously with layered process, and therefore highly improve working efficiency and workpiece surface quality.

2) High precision and accuracy:Heavy-duty structure with good stability, avoid shaking during the spindle rotating fast or the big sizes workpiece processing; furthermore, the spindle speed is adjustable through the inverter. High accuracy stepper motor, through program calculating, guarantees the exact processing size.

3)Easy and safe operation and low maintenance cost:Humanized and updatable operation system and USB interface, easy and convenient to change the working pattern without live programming.

4) Good Compatibility:Freely design and engrave all kinds of patterns and text, which are designed by Coredraw, Artcam, AutoCAD and other software.

5) Smooth and High-Precision Transmission:Germany ball screw and Taiwan PMI linear square rail with high transmitting precision and long working time.

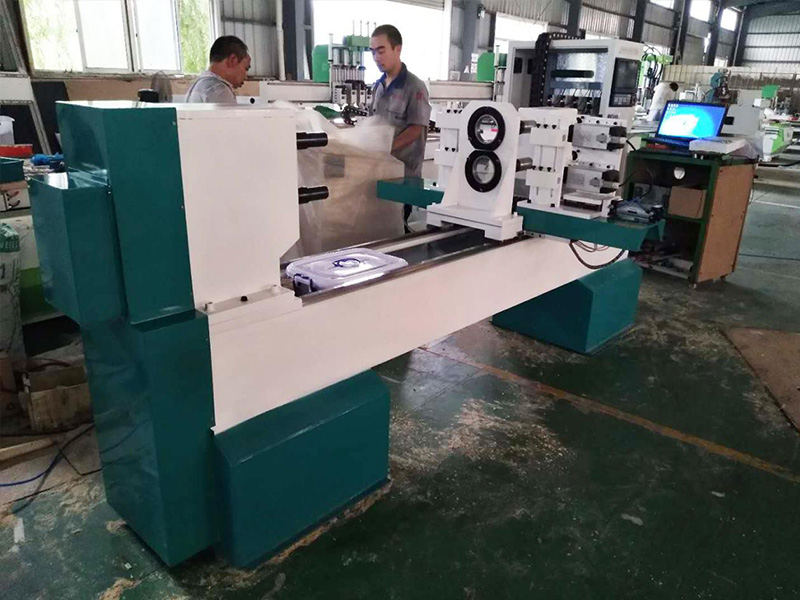

6) Perfect details processing technology:Every detail is treated and inspected very seriously so that perfect machine could be made.

7) Matured and perfect after-sales service system around the clock .

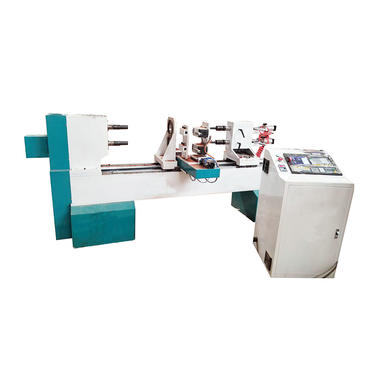

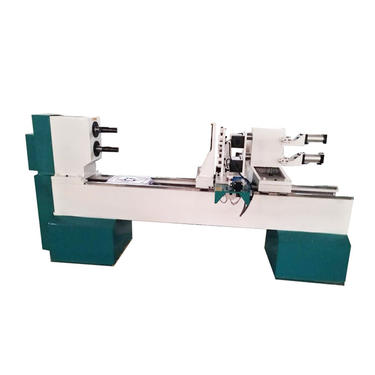

LD-3015 Doule Axis CNC Wood Lathe Machine

CNC wood lathe ( CNC Lathe for making wooden stairs handrails / stairs column / stair wood balusters) According the requirement and characteristics of woodworking industry, CNC woodworking lathe combining CNC and other mechanical technology, could process the complex shape of the wood rotary products or semi-finished wood products. , such as staircase column,cylindrical, conical, curved, spherical etc. It is especially suitable for the mass production of small or medium-scale wood enterprises, set shape flexibly and changing processing style rapidly.

1. operating system: DSP control handle, easy to operate, easy to learn.

2. auxiliary parts: thick steel plate welding, 2.9 meters long, small vibration, deformation, stability.

3. part: the use of frequency conversion speed control system, can adjust the speed of rotation speed to solve the problem of wood flutter.

4. transmission parts: the use of the Taiwan on the silver straight track (square rail, ball screw, ball screw), high precision, stable operation.

5. Control part: Using mature CNC controller, it works steadily and is easy to install and debug. Adopt international standard NC language G code. Support a variety of software, support technical function expansion.

6. Motion part: high-precision stepping motor and yako servo drive, ensure the accuracy of processing size, using Taiwan Guideway, combined with ball screw transmission, strong environmental adaptability, not afraid of dust. Ensure processing.Accuracy. Frequency conversion speed regulation, spindle automatic operation, high degree of processing automation.

7. Bed part: Foundry moulding, stable structure, high frequency quenching grinding imported linear square rail, small vibration, can ensure high precision processing.

Machine structure | Heavy duty,whole body weld, machine gross weight more than2000kg |

Working diameter: | Single axis working max diameter can be 30cm |

Max.length | 200mm—1500mm |

Driver motor | bigger power Stepper motor and Yako 2D811 driver |

Guide | Taiwan Hiwin square guide rail |

Spindle | 3.5KW air cooling |

Spindle rotating speed | 24000rpm/min |

Cable | Imported German cable line, high soft, anti-interference |

Control system | China local famour brand Beijing DSP control system. support in English |

Typeset software | CAD. Jadpint |

Support commend | G code, DXF. |

Voltage supply | 3Phase 380V |

Carving knife | 4 pics on machine, 2 pic for free, ( alloy &steel knife) |

Overall size | 2950*1650*1300mm |

Package | Wooden case |

Packing size | 3.4*2.05*1.7m |

N W | 1800kg |

GW | 2000KG |

Warranty | One year |

Staircase column, vases, furniture legs, European style furniture, Roman column, wooden hangers and washbasin, cylindrical, conical, arc, spherical complex shaped revolving body wood or wood semi-finished products, etc.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts