LED bulb lamp adhesive sealant SD911

our product

Feature

◪ no fog, release alcohol substances when curing.

◪ Using in polycarbonate (PC), copper and other materials, non-corrosive, non-irritating gas release; fully in accordance with the requirements of the European Union ROHS Directive.

◪ It has good adhesion and aging resistance to many kinds of materials. The properties are stable at -50 ℃ and 250 ℃.

Application

1.This silicone sealant is used for bonding and waterproof sealing of barrier pipe in optoelectronic industry.

2.used for bonding and sealing LED bulb lamp, automobile lamp, underwater lamp, washing lamp, hard lamp bar, engineering plastic, metal, glass and ceramics

3.used for bonding ,strengthening and moisture-proof sealing of electronic components on electronic circuit board.

LED bulb bonding

Heat lamp bonding

Hard light bar bonding

Underwater lamp bonding

Glass bonding

Car light bonding

product Performance

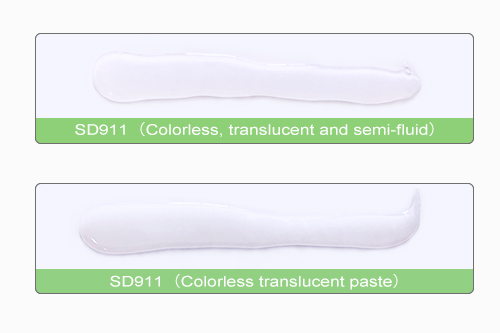

| Item | SD911 | SD911 |

| Appearance | Colorless, translucent and semi-fluid | Colorless translucent paste |

| Density (g/cm3) | 1.0~1.1 | 1.0~1.1 |

| Tack-free time(25℃,min) | 3~10 | 3~10 |

| Tensile strength(MPa) | ≥2.0 | ≥2.0 |

| Elongation(%) | 200~300 | 200~300 |

| Shear strength(MPa) | ≥2.0 | ≥2.0 |

| Hardness (shore A) | 25~30 | 25~30 |

| Temperature range(℃) | -50~250 | -50~250 |

| Dielectric constant(@60Hz) | 3.0 | 3.0 |

| Dielectric strength(kV/mm) | ≥20 | ≥20 |

| Volume resistivity(Ω.cm) | 2.0×1015 | 2.0×1015 |

Product details

Use instructions

Clean the surface of objects which to be sticky or coated, remove rust, dust and oil.

First prick the rubber pipe with the cap tip, put the tip on, squeeze the glue into the cleaned surface, distribute it evenly, and fasten the adhesive surface together.

The coated parts are placed in air and solidified at room temperature for 24 hours.

Caution

After the operation is completed, the silicone sealant should tighten the cap immediately and seal and save. When reusing, if there is a little skin seal, remove it,this will not affect the normal use.

Packaging and preservation

Packing specification: 45g/pcs, 300ml/ pcs or as required by customer.

Storage: stored in a cool and dry place for 12 months.

Note: The above data are based on our extensive experiments and the results are reliable. However, due to the diversity of practical applications, the application conditions are not within our control, so users need to conduct tests before using to confirm whether this product is applicable or not. We do not warrant any problems arising from the use of our products under specified conditions and are not liable for any direct, indirect or accidental loss. If any problems in usage, you can contact our technical services department, we will do what we can to help you.

Contact

Supplier