Light Weight Mullite Brick for Furnace Insulation

What is the details of our brick insulation ?

1. brick insulation is made by high purity fire clay, by adding combustible, gas evolution method,

or foam method.

2. Al2O3 content of brick insulation : 30-46%.

3. Working temperature of brick insulation :

less than 1300°C,Max working temperature:1200°C - 1400°C.

4. Good thermal resistance and strong ability to resistant acid slag.

What is the Technique Data of our brick insulation ?

Item | brick insulation | |||

0. 6 | 0.8 | 1.0 | 1.3 | |

Al2O3 (%) | 40 | 40 | 40 | 40 |

Fe2O3 (%) | 1.5 | 1.5 | 1.2 | 2 |

SiO2 | 55 | 55 | 55 | 55 |

Bulk Density (g/cm3) | 0.6 | 0.8 | 1.0 | 1.3 |

Apparent Porosity % | 70 | 60 | 55 | 50 |

Cold Crushing Strength(Mpa) ≥ | 2.0 | 2.5 | .0 | 4.0 |

Reheating Linear Change (%)°C X 12H ≤ | 1300℃ -0.5 | 1350℃ -0.5 | 1350℃ -0.9 | 1350℃ -0.9 |

Thermal Conductivity(W/m.k)(1000°C) | 0.33 | 0.60 | 0.45 | 0.8 |

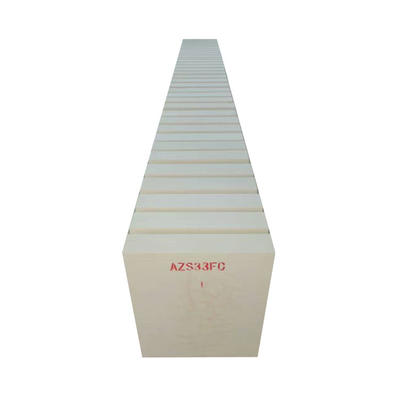

Our brick insulation display:

What is the Feature of our brick insulation ?

1.Low line expansion coefficients;

2.Long service life;

3.High porosity, low volume density, low thermal conductivity;

4.Good heat insulating effect and energy-efficient;

5.Good thermal shock stability;

6.Corrosion and erosion resistance;

What is the Applications of our brick insulation ?

1. As inner lining brick of industry kilns wall and industry furnace, such as: annealing furnace, carbide furnace, tempering furnace, refining furnace, furnace, roller kiln, tunnel kiln, etc.

2.The backing insulation materials for various kinds of industrial furnace.

Our brick insulation Production process:

Crushing → Mixing → Shaping → Drying → Firing → Inspection → Packaging and Shipment

Our brick insulation quality control:

Lite Refractory is committed to high quality standards for all its products and services. After the fireclay bricks are fired, our team will test the products with equipments as follows to meet all technical dates.

Testing equipment:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

Packaging:

1. On wooden pallets with plastic cover.

2. According to customer's demands.

3. We will do our best to avoid the goods damage and secure the brick insulation in transportation.

Shipping:

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods.

3. Delivery time: within 25 days

1.Strong professional:

Our company, Henan LiTe Refractory Material Co.,Ltd is located in Zhengzhou Henan province,

which is one of the main refractory production bases in China.

We are professional manufacturer in brick insulation with more than 10 years experiences.

2.Annual supply:

Our factory has passed ISO9001 quality management system certification. And the annual supply of shaped and unshaped refractory product is 28,800-35,000 tons.

Delivery time can be guaranteed with high quality.

3. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece,Spain, Congo, Angola, South Africa, and Maldives,Jordan and so on. The export figure is more than USD 4 million.

4. Certificates:

5.Customers visiting:

Now customers from Pakistan,Russia,Saudi Arabia,Kazakhstan etc have visit company and factory! Waiting here for you!

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the insulation firebrick will be tested, and the quality certificate will be

shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample of brick insulation for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

6. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

If you have any question, just contact us, our team will try our best to serve you !

Contact person: Ellen

Skype:Nancy Huang Whatsapp & WeChat:(86)18736996752

TEL:(86)18736996752

Henan Lite Refractory Material Co.Ltd

Tel: +86-0371-55178866

Fax: +86-0371-55178866

Add: Zhengzhou city, Henan province, China

Website: www.literefractory.com http://literefractory.en.alibaba.com

Thanks for reading our websites!

If you have any questions about our products, please contact us at any time, we will answer you asap!

Contact

Supplier