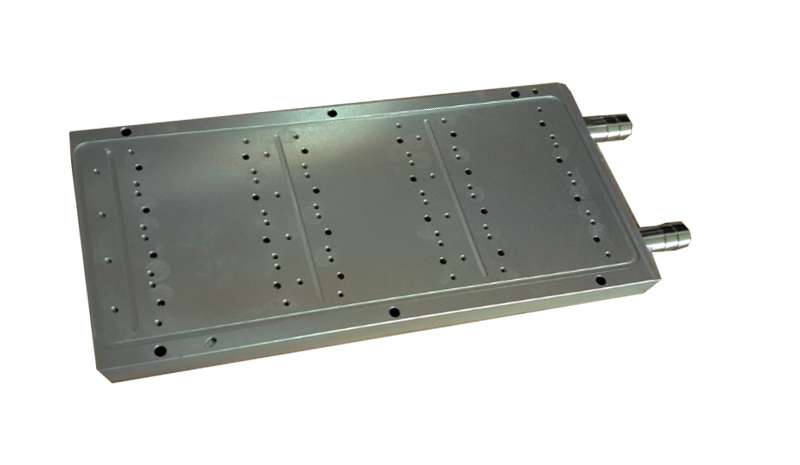

Liquid Cold Plate with Friction Stir Welding Process

| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | Friction welding | Temper: | T3-T8 |

| Material: | AL6061 | Shape: | Square |

| Packing: | Standing Export Packing | Brand Name: | LORI |

| Application: | Laser Project | Certificate: | ISO 9001:2015,ISO 14001:2015 |

| Model Number: | LR0142 | Tolerance: | 0.01 mm |

| Finish: | Hard anodizing | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | Custom size |

Liquid Cold Plate with Friction Stir Welding

This liquid cold plate with friction stir welding base material is AL6061, A longitudinal channel is formed on the base through friction stir welding, and then it is milling through at both ends of the transverse interval, and the channel is closely connected by friction stir welding. In the direction of more compressive strength and thinner thickness, this technology has been successfully applied to the liquid cold plate of high power laser equipment.

The surface treatment technology of hard anode is made possible by the material with similar composition and the friction stir welding process without adding solder.

This liquid cooled plate finished with hard anodized, so the laser equipment can withstand the test of harsh service environment and long-term fluid erosion.

Friction stir welded liquid cold plate applied to Electric Automobile, Semiconductor, Optical communication, Military transmitter, IGBT, Laser,and other high power devices.Etc.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.

Contact

Supplier