WHY Maydos? ![]()

Capable — Top 5 manufacturer in China! Biggest factory in Asia!

Professional — 10 years' experience for export!

Eternal — Stable quality and price!

Supportable — Overseas technical support and return visit after sale!

Description:

Maydos SBS Adhesive KK06-L is formulated with high quality imported materials. It has good features such as easy application, rapid drying speed, powerful viscidity and ultraviolet radiation resistant after solidification, damp and aging resistant.

Advantages:

1. Environmental-friendly: Extraordinary low benzene and VOC, no hazardous materials and additives.

2. High solid content: 34% solid content, much higher than conventional adhesives, which can save adhesive

consumption by 30%-40%.

3. Freezing temperature resistant: no influence even at -15℃ to -20℃ and easy for transportation and bonding in

winter.

4. Super initial bonding power, good penetration property and fast drying speed.

5. Stable performance: moisture and water-immersion resistant after hardening, good impact resistant, which

assures long service life.

Where to Use:

Suitable for bonding materials such as plywood, board, wood floor, wallpaper, rubber, fireproof board, aluminum-plastic board and cloth, etc.

Technical Data:

Appearance: Light yellow viscous liquid

Viscosity: 55-60 ku / 30℃

300-550 MPa. S/25℃

Solids Content: 34%-36%

Shear Strength:

30 minutes: ≥0.7mpa

48 hours: ≥1.1mpa

Specific Gravity: 0.86-0.87kg/L

VOC: ≤700 g/L

Dosage: 195-250g/m2

Shlef Life:

12 months in sealed tins.

Packing Size:

0.5kg, 0.8kg, 2.2kg, 3kg, 15kg, 160kg.

Application Tools:

Brush, scraper etc.

Application Method:

1. Surface preparation: Bonding surface should be dry, clean and free of dust and rust. Smooth surface such as

plywood, rubber, must be sanded first to make it coarse. After that, clean the surface and apply the adhesive.

2. Gluing: Mix up the adhesive before use. Pour adhesive on the two bonding surfaces separately and spread it

with brush or scraper. To achieve the best bonding performance, the application should be done toward the

same direction and evenly.

3. Airing: After application of the adhesive, enough time should be given to let the solvent evaporate completely to

avoid bubble or stickiness.

4. Bonding: The application should be done once and for all. Aim the two surfaces, bond together and press. Don’t move the two surfaces back and forth, or the bonding effect will be weakened.

Storage:

Keep it out of touch of children and store in cool, dry and ventilated place. The storing temperature shall range from 5 - 35 Celsius, and the relative humidity shall be<80%.

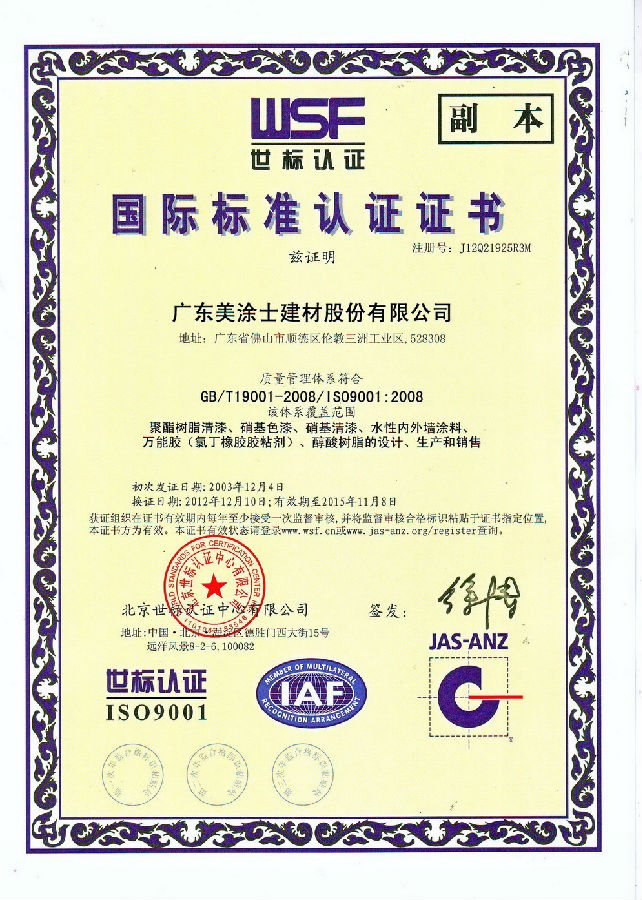

Certificates:

Contact

Supplier