WHY Maydos? ![]()

Capable — Top 5 manufacturer in China! Biggest factory in Asia!

Professional — 10 years' experience for export!

Eternal — Stable quality and price!

Supportable — Overseas technical support and return visit after sale!

Description:

Maydos PU Shoe Adhesive PA01 is colorless and semi-transparent. It has such features as non-yellowing, easy application, rapid drying speed, powerful viscidity, ultraviolet radiation, aging and damping resistant after solidification.

Advantages:

1 .Excellent oil resistant and anti-skidding performance.

2. Strong initial bonding force.

3. Yellowing and freezing resistant.

4. Low odor and good liquidity.

Where to Use:

Mainly used for PVC, PU, TPR, genuine leather, artificial leather, flannel, rubber, furniture, sports material etc. Better oil resistant performance, lower odor and shorter operation time than other brands of PU adhesive in the market and it is suitable for both assembly line and handwork.

Technical Data:

Appearance: Colorless liquid

Solvent type: Compound of Toluene, MEK, etc.

Viscosity: 1600-2000 Mpa.S/25℃

Solids Content: 13%-15%

Shear Strength: ≥1.8mpa

Removing Strength: ≥600N/cm2

Specific Gravity: 0.85kg/L

Initial bonding power: ≥0.6mpa

VOC: ≤750 g/L

Shlef Life:

12 months in sealed tins.

Packing Size:

0.5kg, 0.8kg, 2.2kg, 3kg, 15kg, 180kg.

Application Tools:

Brush etc.

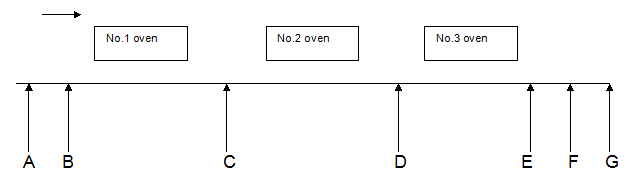

Production line arts & crafts procedure diagram:

A. Genuine leather and rubber sole sanding.

B. Applying treating agents on the sole and upper vamp.

C. Applying adhesive on the sole and upper vamp for the first time.

D. Applying adhesive on the sole and upper vamp for the second time.

E. Bonding.

F. Press with pressing machine.

G. Check the shoes quality after 24 hours.

Application Instruments:

1. Control the temperature of the No.1 oven between 70-75℃.

2. Control the temperature of the No.2 oven between 60-65℃.

3. Adjust the transferring speed of production line to prolong the time of processing shoe in No.2 oven,

approximately 6-8 minutes.

4. The distance between the pressing machine and the No.2 oven is about 2/3 length of No.2 oven.

5. The added hardener is about 3-5% of the adhesive.

6. The rubber sole should be sanded evenly and completely to avoid adhesive coming off.

7. The cattle hide and PU film leather should also be sanded deeply and completely to avoid adhesive coming off.

Storage:

Keep it out of touch of children and store in cool, dry and ventilated place. The storing temperature shall range from 5 - 35 Celsius, and the relative humidity shall be<80%.

Certificates:

Contact

Supplier