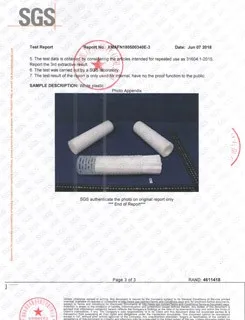

Polypropylene melt blown filter cartridge or PP spun water filter, PP filter, PP filter cartridge is the most widely used filtration consumable products in domestic and industrial water treatment systems.

Melt Blown sediment filter cartridge has strong pollutants holding capacity.