Near Field Direct Wiring Electrospinning Equipment M08

ORIENTED ELECTROSPINNING NANOFIBER FABRICATION: CELL CULTURE SCAFFOLD PRINTER

/ Technical Data

Near Field Direct Writing ELECTROSPINNING Equipment M08-001 Standard Configuration | ||

No. | Item | Parameters |

1 | High Voltage Power Supply | Output voltage: 0-30KV adjustable |

2 | Nozzle System | Molten nozzle |

3 | Motion System | X, Y-axis |

4 | Collection System | Conducting glass, track collection |

5 | Temperature System | Precision control temperature |

6 | Viewing System | Camera |

7 | Pressure System | Precision pneumatic |

8 | Control System | PC man-machine control |

9 | Safety System | Multiple protection |

Optional Configuration | ||

No. | Item | |

1 | Customized X-Y platform precision | |

2 | Temperature controlled collection platform | |

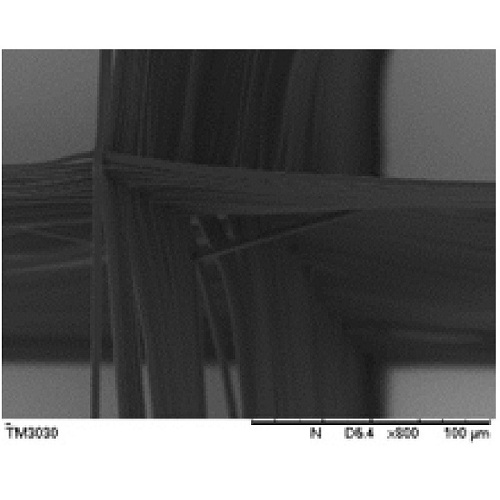

PRINCIPLE OF NEAR-FIELD ELECTROSPINNING

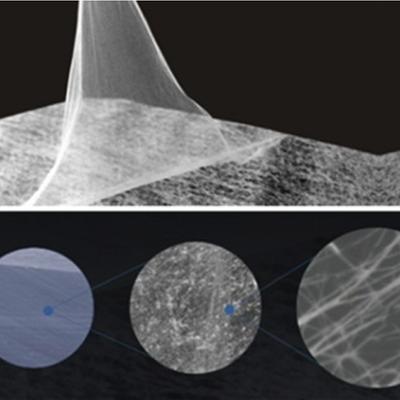

In 2006, QINGZI group firstly developed the techniquqe of near-field electrospinning. Precisely ordered and highly oriented nanofiber arrays were prepared when the collector was placed 0.5-5 mm to the nozzle and the motion of these two parts was precisely controlled.

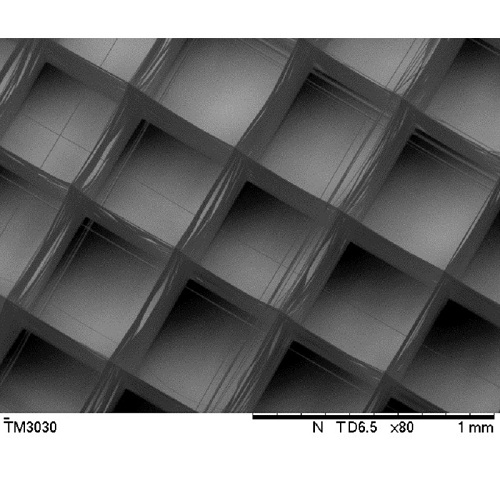

NEAR-FIELD ELECTROSPINNING TECHNOLOGY SAMPLES

3D scaffold, complicated patterns

NEAR-FIELD ELECTROSPINNING TECHNOLOGY

Solution near-field electrospinning

Printing materials were firstly dissolved in solution. During the near-field electrospinning process, the solution jet was stretched by the electrostatic repulsion, and fibrous products with diameter range from 50 nm-20 μm could be collected. Fibrous products prepared through this technique are highly applicable.

Melt near-field electrospinning

Printing materials were firstly melted by heat treatment. During the melt near-field electrospinning process, the molten fluid was stretched by the electrostatic repulsion, and fibrous products with diameter range from 500 nm-50 μm could be collected. Fibrous products prepared through this technique are suitable for the fabrication of 3D bio-scaffold.

NEAR-FIELD ELECTROSPINNING MACHINE PARAMETERS

High voltage power supply: 0-30 kV adjustable;

Solution spinning needle: solution supply volume minimum 10μL/h;

Melt spinning needle:(1) temperature range:0-300℃ adjustable; (2) precision pneumatic extrusion;

Environment temperature range:room temp up to 50℃ adjustable;

Collection platform:(1) printing area: 150*150mm; (2) motion platform speed: 0-200 mm/s adjustable;

Z axis: 0-80 mm adjustable;

Printable materials: PEO, PVA, PLA, PCL, PLGA, chitosan, sodium, alginate, collagen, hydroxyapatite, PVDF and other hundreds of organic or inorganic materials;

User-defined patterns printable;

3D structure printable;

Optional: collector temperature controllable; multi-needle device.

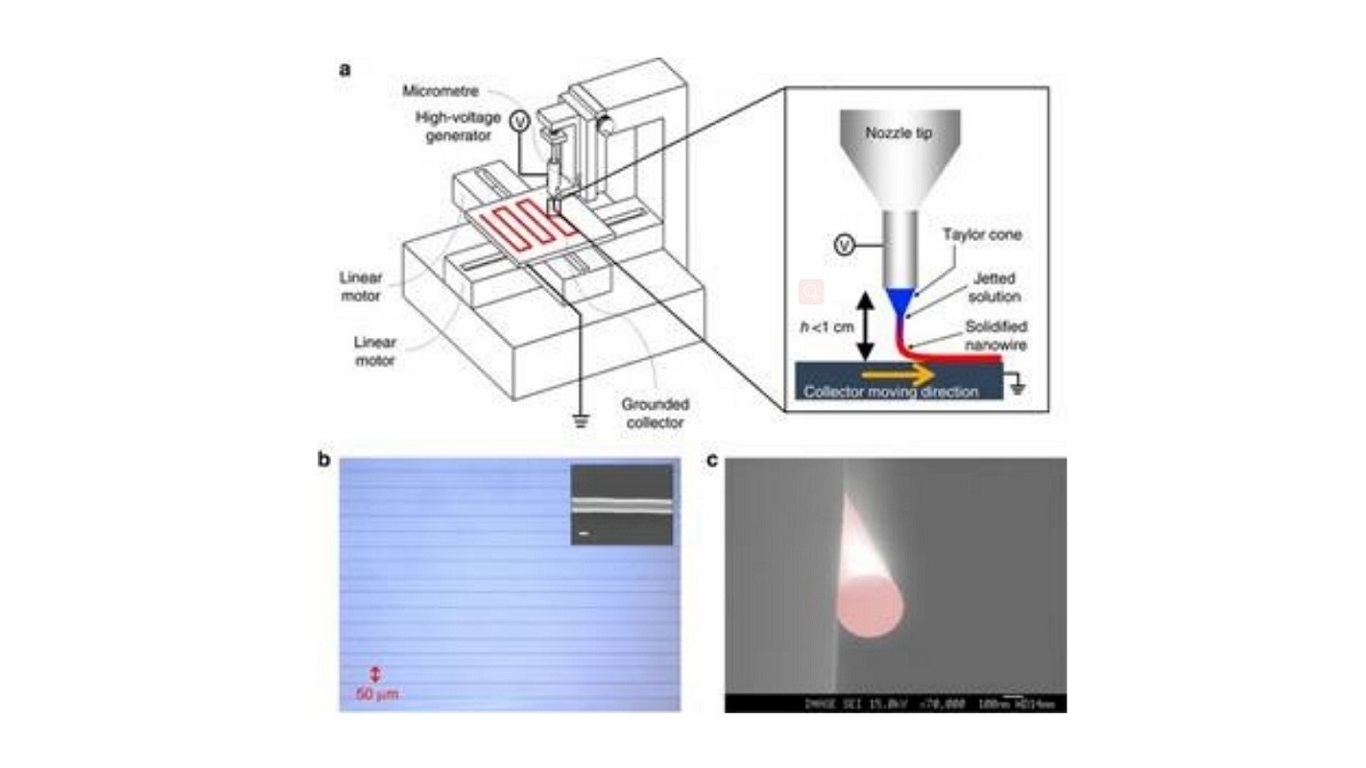

NEAR- FIELD ELECTROSPINNING APPLICATION

/ Product Application

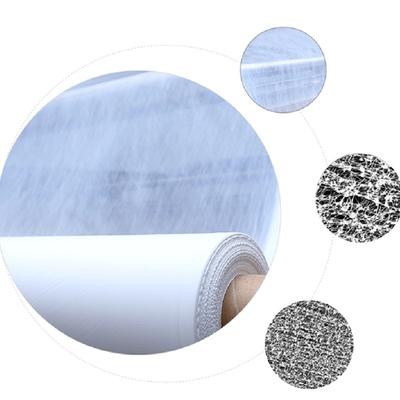

◆ Polluted waste treatment: Heavy metal ion adsorption, Acid-base treatment, organic waste gas treatment, organic wastewater treatment, small molecule pollutant adsorption, etc.;

◆ Filtering Separation: Suspension particles, PM2.5 mask, Air filtration, water filter, sifting, oil-water separation, extraction, seawater desalination, etc.;

◆ Biological medicine: drug delivery, dressing, drug extract, tissue engineering scaffold, Biological testing, Cosmetics, antimicrobial, artificial organ, enzyme immobilization, etc.;

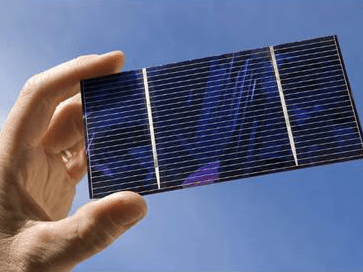

◆ New energy: organic solar cells, li-ion electrode material, sodium-ion battery material, fuel cell, li-ion battery separator, photocatalytic hydrolysis, etc.;

◆ Electronic information: gas sensors, humidity sensors bioinstrumentation, flexible circuit, microfluidic chip, micro/nanodevice etc.;

◆ Catalysis: Organic wastewater and gas catalytic treatment, photocatalysis, chemocatalysis, etc.;

◆ Defense Industry: missile insulation, stealth wave-absorbing, light isolated material, electromagnetic shielding, etc.;

◆ Other: food processing, composite enhancing, antiseptic antistaling, waterproof and moisture permeable, aerogel, high temperature insulating, keeping warm, etc.;

/ Our Services

◆ The best quality and lowest price can meet your requirement.

◆ Impeccable after-sales service will solve all problems after your purchase.

◆ Guide you installing.

◆ Immediate reply within 24 hours on line.

◆ If you come to our company, please let us know in advance, we will offer you a correct traffic route.

Winnie Chan

International Trade Manager

Mob./Whatsapp: +86 18520902852

QQ: 1130008454

WeChat: QingziNano

E-mail: winnie@qingzitech.com

Tel.:+86 757-89956076

Web. : https://www.qingzitech.net/

Facebook: https://www.facebook.com/LeptonChina/

Twitter: https://twitter.com/?lang=zh-cn

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts