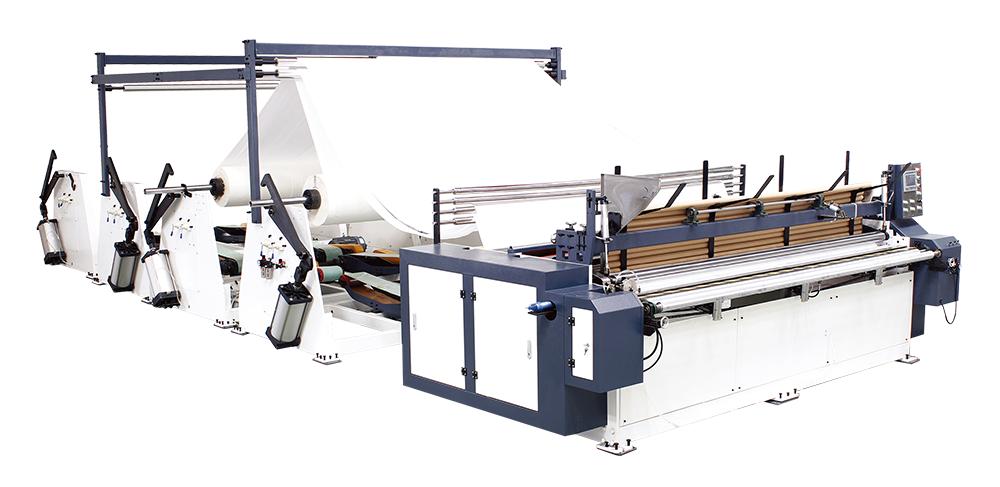

OPFJ-250B Full Automatic Toilet Roll Rewinding Machinery

Mechanical structure | (1)Rectangular steel pipe welded with steel plate. | |||

Paper Unwind Stand | (1) Two independent drive unwind stand, with pneumatic parent roll lifting system | |||

Automatic tail trimming and sealing system | ||||

Automatic core feeding (alarming when core finish) | ||||

| Coreless device | ||||

Equipped with PLC, HMI (Siemens brand) | ||||

Equipped with inverter speed control (INVT brand) | ||||

Main motor use Siemens brand | ||||

OG and Emergency stop control | ||||

Installed Power: Main Motor: 7 KW, Stand motor:2.2KW, Glue Motor: 550W | ||||

Air supply | 5KG/cm²Pa (6L/min) 0.6MPA, Air compressor user provide. | |||

Required voltage | 3 phase 380V/50H | |||

Machine siz | 15000*3250*2000mm (2 Stands + Lamination unit + Rewinder) | |||

Machine weight | about 14.0 tons | |||

OPTION | ||||

| Double Embossing Units – deco printing lamination system or point to point system | (1) Rectangular steel pipe welded with steel plate (2) Thickness of machine wall board is 50mm, process by numerical CNC. (3) Steel to rubber embossing,2 Steel cylinders ф320 mm,2 Rubber cylinder ф240 mm (4) Lamination unit: rolling gluing system –2 rubber cylinder, (5) With independent motor and inverter control (6) With JOG and Emergency stop (7) Power requires: 15KW | |||

Single embossing equipment | (1) Rectangular steel pipe welded with steel plate (2) Thickness of machine wall board is 51mm, process by numerical CNC. (3) Steel to rubber embossing, with air control (4) Steel cylinder diameter 240mm (5) Independent motor drive, inverter speed control, easy to suit to different paper tension (6) Embossing design user provide (7) Power requires: 7.5KW | |||

Edge embossing equipment | (1) 22sets of embossing bearing wheel. Laser engraves depth 0.5mm. (2) With air control (Bearing steel bottom cylinder, diameterφ205mm, hard up to HRC60 | |||

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts