Polypropylene Spunbond Nonwoven Fabric

PP SPUNBOND NONWOVEN FABRIC

The PP Nonwoven Fabric Manufacturer Sunshine has 13 production lines that both in domestic machines and reifenhauser machines, can cater to the needs of different types of customers.

Our fabric has different weight,width,color etc.suitable for many different fields and play an important role in these areas.

Character:

● 100%Polypropylene

● Excellent Air Permeability

● Wide Range applications

● Anti-Pull

● Tear-Resistant

● Direct contact with food

● Good Uniformity

● Waterproof

● Cheapest alternative in same usage

PRODUCT PARAMETERS

Fabric,SS/SMS/SMMS/SSMMS Nonwoven Fabric and its processed products for you

PROPERTIES | TEST METHOD | UNIT | ||||||||

WEIGHT | ERT40.3-90 | g/sq.m | 12 | 17 | 30 | 50 | 70 | 90 | 100 | |

THICKNESS | ERT30.4-89 | mm | 0.12 | 0.17 | 0.28 | 0.38 | 0.46 | 0.53 | 0.58 | |

TENSILE STRENGTH | ERT20.2-89 | n/5cm | MD | 24 | 33 | 61 | 104 | 145 | 178 | 195 |

CD | 19 | 25 | 54 | 89 | 127 | 160 | 174 | |||

ELONGATION | ERT20.2-89 | % | MD | 54 | 50 | 77 | 76 | 66 | 75 | 71 |

CD | 59 | 84 | 81 | 83 | 72 | 86 | 76 | |||

TEAR STRENGTH | ERT70.4-99 | N | MD | 18 | 18 | 38 | 60 | 74 | 77 | 78 |

CD | 20 | 31 | 43 | 68 | 85 | 90 | 90 | |||

AIR PERMEABILITY | ERT140.2-99 | cm3/cm2.sn | 185 | 170 | 145 | 130 | 115 | 80 | 70 |

The PP Nonwoven Fabric Manufacturer Sunshine has 13 production lines that both in domestic machines and reifenhauser machines, can cater to the needs of different types of customers.

Our fabric is breathable,biogradeable with 100% first class PP,suitable for many different fields and play an important role in these areas.

so we can provide ODM/OEM SERVICE to satisfy customers’ needs.

the actual color is subiect to the actual product

Getting Color Method:

◪ Choose the color from our sample book.

◪ Give us the Pantone color.

◪ Send us your color,we do as your request.

Contact us for free sample and 2-3% discount!

Fabric,SS/SMS/SMMS/SSMMS Nonwoven Fabric and its processed products for you

◪10gsm-40gsm:

◪ Character:1.Thin Thickness 2.Soft Cloth Surface. 3.Excellent Air Permeability

◪ Usually used in baby diaper,interlining fabric,plant cover,filter fabric,face mask etc.

◪ 40gsm-80gsm:

◪ Character:1.Wide Range applications2.Anti-Pull3.Tear-Resistant 4. Direct contact with food

◪ Usually used as Table Cloth,Disposable Bedsheet, Weed Cobtrol,Flower and Gift Wrapping,Making Shopping Bags,

◪ Also can be used in Furniture,Medical and Home Textile Industry.

◪80gsm-150gsm

◪ Character:1.Good Uniformity 2.Waterproof 3. Hidrophobic

◪ Used in Luggage

please cintact us for online monitoring checking .

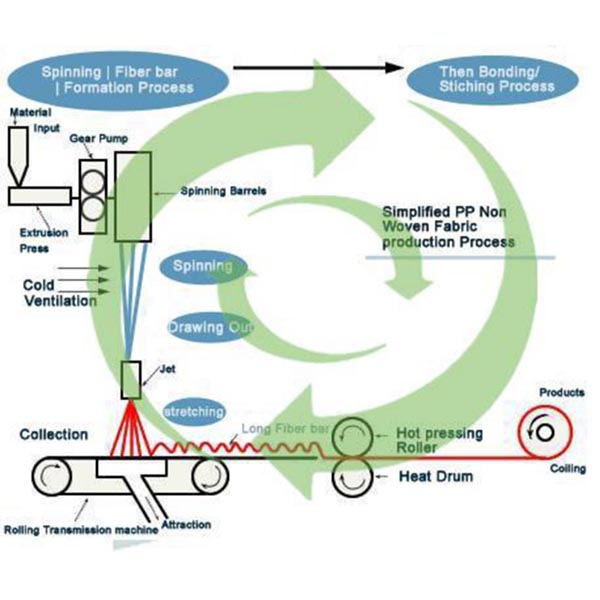

Sunshine make PP Nonwoven Fabric with SPUNBOND technology, the full name is Spunlaid Termobonded. By spunbond,the resin polymer of polypropylene is melted in the extruder and the resulting fibers are cooled by a cold air stream. These fibers form a web and the web thermally joined to a heated roller press which provides heat sealing of the fibers, giving the fabric its peculiar texture.

We supply different package for you.

Contact

Supplier