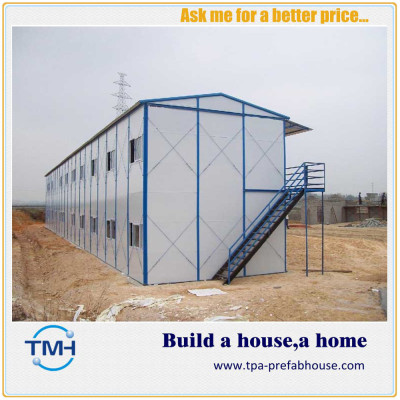

Prefabricatied Steel Structural Dairy Farm Shed with Customized Size--TPA-SSH01

Prefabricatied Steel Structural Dairy Farm Shed with Customized Size

Steel Structure building is a new type of light steel structure building system formed from a main steel framework comprised of H section, Z section and U section steel components, the roof and walls utilizing a variety of panels and other components, such as windows, doors and cranes.

The light steel structure building is widely used in the factories.

Main materials of the steel structure building

1. Q235, Q345 H section steel structure for columns and beam

2. Pre-embedding anchor bolts for connection columns to foundation

3. Intensive bolts for connection between columns and beams

4. Wall/roof panel: one layer corrugated steel plate or sandwich panels

5. Windows/doors, PVC, aluminum alloy, steel, etc.

6. Color steel plate or galvanized steel gutters and PVC tubes for rain water

Characteristics

1. Possesses a wide span, with either a single or multiple spans and can have a maximum span clearance distance in 36m without middle columns.

2. Low cost with unit price ranging from R 500 - R 1000 per square meter

3. Fast construction and easy installation

4. Has a service life of more than 50 years

5. Environmentally friendly, have a stable structure, are earthquake resistance, water proof, and energy saving.

Application

The steel structure building is widely used in the construction of buildings such as warehouses, workshops, and large factories.hangar/garage/chicken shed, exhibition hall, agricultural storage, logistic centers etc.

| Why Us |

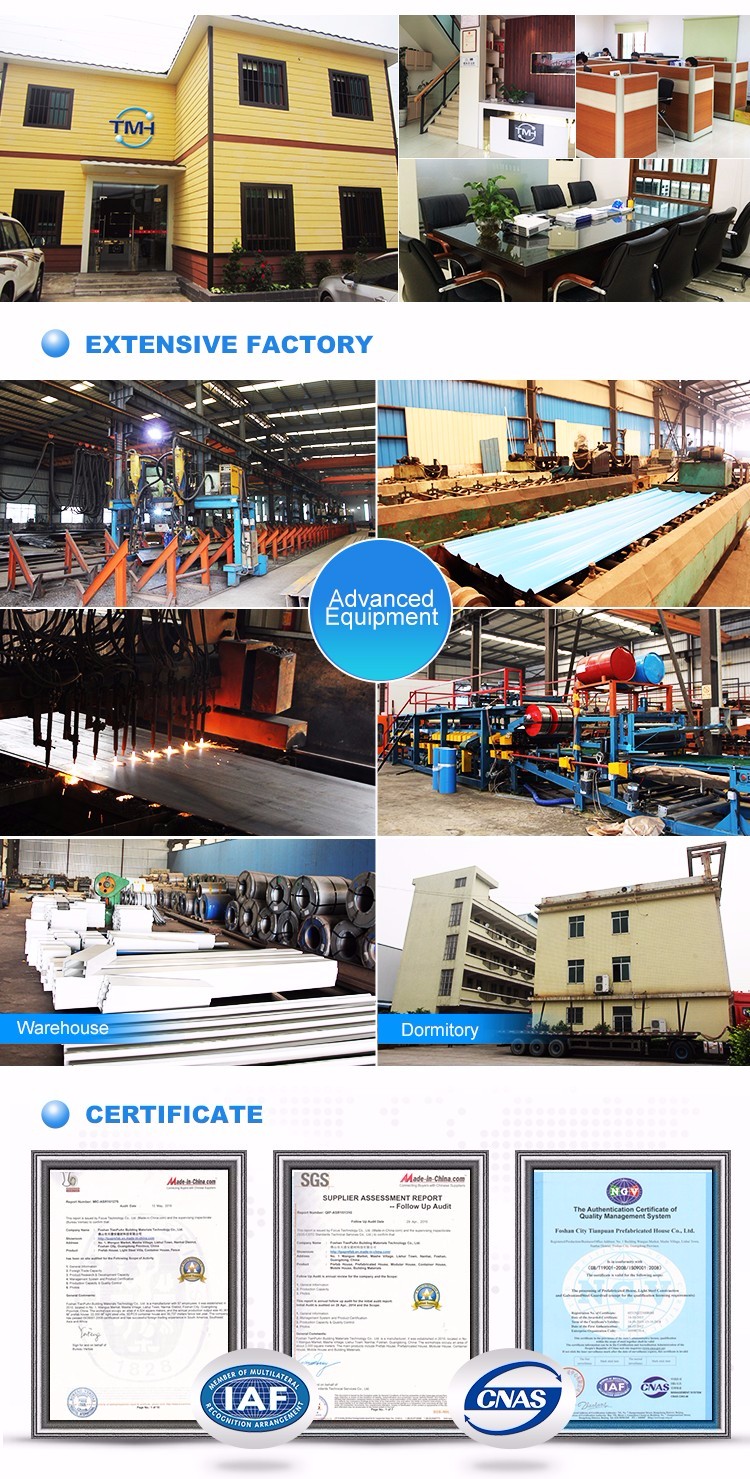

TianPuAn Building Materials Technology Co.,Ltd., also known as TianPuAn Prefab house Co. Ltd. It was founded in 2005. Since then, we have been a professional manufacturer of steel structure building,container house,prefabricated house,light steel villa, fence,sandwich panel and profiled steel with ISO9001 certification. |

| Company Overview |

We focus on producing custom-made economic and environmentally friendly prefab house.With the Specialized technology,professional design team and high-quality construction team we undertaken hundreds of prefab buildings production and installation,got the consistent high praise of the clients.Our capacity is about 30000 to 50000 square meters per month.. |

FAQ

1.What is prefab house?

A prefab house is shortened name for a prefabricated house, which is a home/house that has components manufactured in an off-site industrial facility. They are sometimes referred to as factory-made or modular houses, although there are some differences.

2.What Are The Advantages Of Your Prefab House?

Light weight,wind resistance,anti-seismic,fire proof,sound proof,environmentally friendly, Quicker to build, Cost effective etc.

3.What is your product range?

We specialized in design and manufacturing prefab house,container house,light steel structure villa house,steel structure,guard house and fence as well.

4.What are your house made of?

Our Prefab house is made of light steel structure and cement board or sandwich panels for the walls and roof.The wall/roof panel can be polystyrene, polyurethane, rock wool, fiber glass sandwich panels.The structure is connected by bolts and the walls are fixed with rivets.

5.Prefab house Installation time?

It depends on the house specification and the house building materials.Usually,sandwich panel house type 4 skilled workers can finish80-100/sqm in 8 hours.Villa house type 4 skilled workers can finish 80-100/sqm in 15-20 days.

6.What Should Be Prepare For The Site Before Start To Built?

At the very least, you will need concrete piers for the columns to sit upon. Most people pour a full foundation, but if you are using the building on a farm or ranch and plan to have dirt, gravel, or sawdust floors, a pier system may be preferable. In these situations, a popular option is to combine piers with a concrete footing around the perimeter of the building.

We'd love to give fully support for your further inquiry!

Contact

Supplier