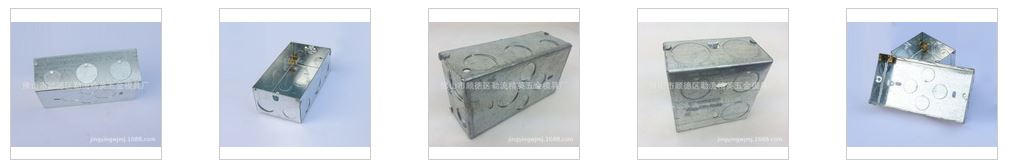

Progressive Tool For Electrical Junction Box

size: 72*72*35mm

72*72*47mm

132*72*35mm

72*72*47mm

Material: galvanized sheet

Mold Material: P20, SKH-9, Cr12Mov, SKD11 etc.

1.Upper& Lower die holder material is good quality 45# steel.

2.Mold punch forming part material is imported SKD-11.

3.Mold plate material is Cr12 national standard.

4.The forming parts material of the mold is YG8 alloy.

5.The inspection material is offered by your part.

6. It is FOB price.

7.Delivery time : 60 workdays

Electronic Box Full Automatic mold . The Front Inductor is imported from Japan.

Mold Life: 1 million

Sized is customized, Stamping Support your cavity is available.

Service after sell abroad is provided.

Mold Trial Press Machines is 40ton-220ton.

Product Features:

Ideal for fire rated walls and ceilings

Raised ground screw eliminates interference in surface mounting applications

Eccentric knockouts for versatile installation applications

Contact

Supplier