The project is located in Huanggang Middle School in Conghua District of Guangzhou City. The main body of the stress is based on the steel structure, and the force carrier is the cable structure. The tensioned membrane unit is uniformly loaded on the cable structure to ensure the stability and applicability of the structure. Using professional membrane structure software, the construction and installation simulation analysis calculations were performed at both local and whole levels, including detailed simulation analysis of the distribution and installation of typical structural units; and the overall structure of the shelter was divided into steps according to the construction tension sequence. The simulation of force analysis. The results of force analysis fully show that the structural roof fully utilizes the overall bearing capacity of the structural foundation, maximizes the effectiveness of the material mechanics, and has the characteristics of novel design, unique structure, attractive appearance, and magnificent appearance.

This type of styling is suitable for awnings such as sports stands, sunshades, sports plazas, residential entrances, and commercial streets. The styling is simple and generous, and its styles are different.

PVC tensile fabric membrane canopy for sports ground

Material Parameter

◪ 1.The steel pipes used are all hot-pressed seamless steel pipes, all of which are made of Q235 and conform to GB700-88. |

◪2.The joint between the pipe and the pipe and the connection between the pipe and the connector are either butt welds or full circumferential fillet welds. |

◪ 3.All butt welds must be cut-through welds. These welds are graded three. |

◪ 4.Welds are fillet welds, with solder fillets of not less than 4mm and all exposed seams have sealing plates. |

◪ 5.Bolts are galvanized ordinary large hex head bolts, in line with GB5780-86; nuts in line with GB41-86. |

◪ 6.Manual welding using E43xx electrode. |

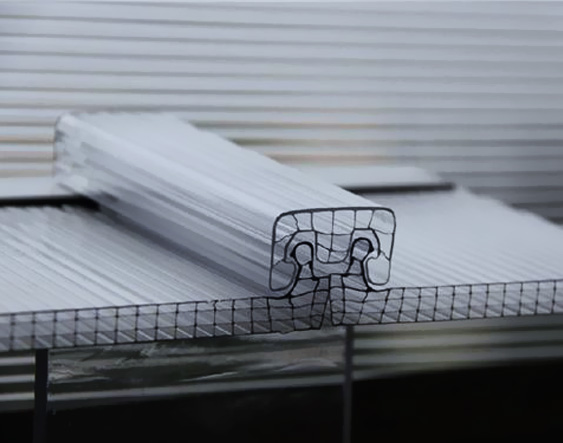

◪ 7.The film is made of white PVDF film. |

◪ 8.The material of the steel wire rope conforms to the universal wire rope standard "GB/T8918-1996". This project adopts a ramie wire rope with a nominal tensile strength of 1570 and the surface is galvanized. |

Contact

Supplier

Aluminum Composite Panels

Balustrades & Handrails

Bathroom

Boards

Building Glass

Ceilings

Countertops,Vanity Tops & Table Tops

Curtain Walls & Accessories

Decorative Films

Door & Window Accessories

Doors & Windows

Faucets, Mixers & Taps

Flooring & Accessories

Formwork

HVAC Systems & Parts

Kitchen

Ladders & Scaffoldings

Masonry Materials

Metal Building Materials

Mosaics

Quarry Stone & Slabs

Real Estate

Stairs & Stair Parts

Tiles & Accessories

Door, Window & Accessories

Stone