1.The raw material granule is mixed by PVC resin- oatmeal and P83 nitrile rubber and plastic ,so its shock resistance and elongation at break than PVC,the cost performance is very good.

2.Physical performance:55-85A,temperature range is from -30°C to 90°C.

Reformative PVC-Frame Sash strip B310B

Name:

reformative pvc-frame sash strip

Item code:

b310b

Material:

reformative pvc-frame

Application:

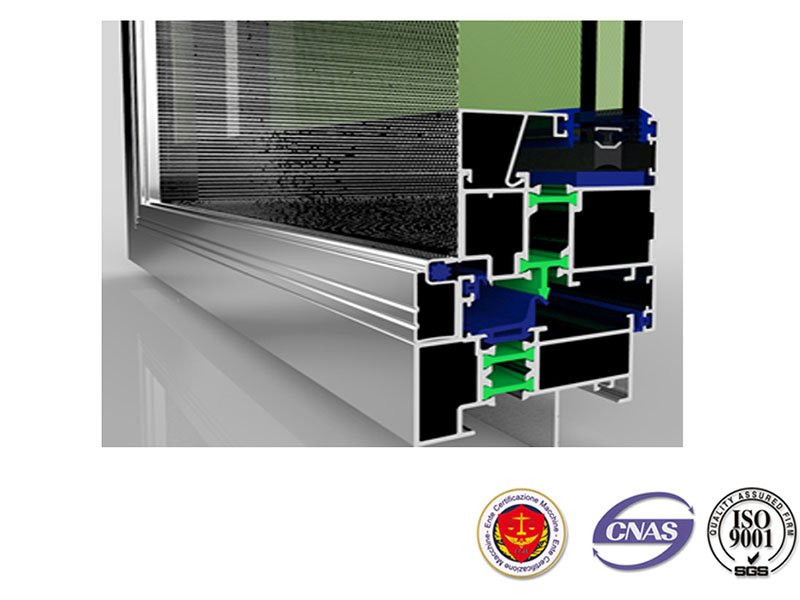

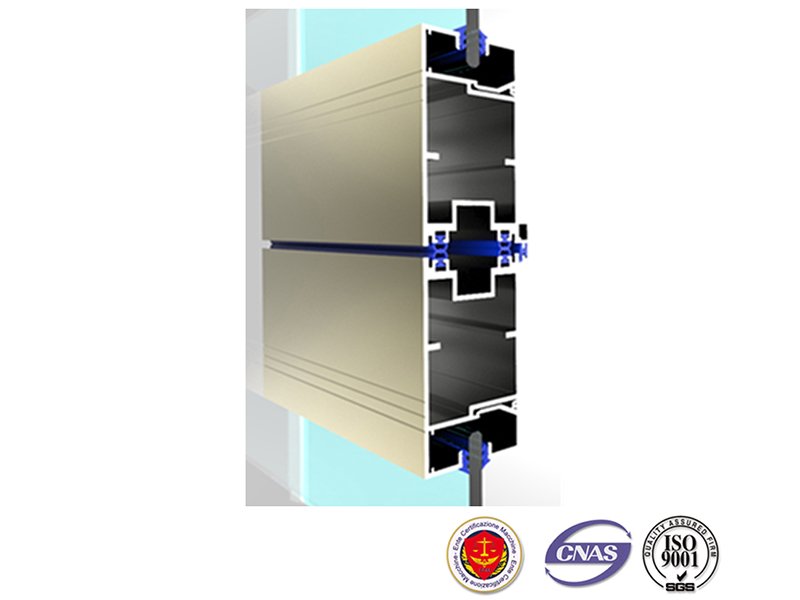

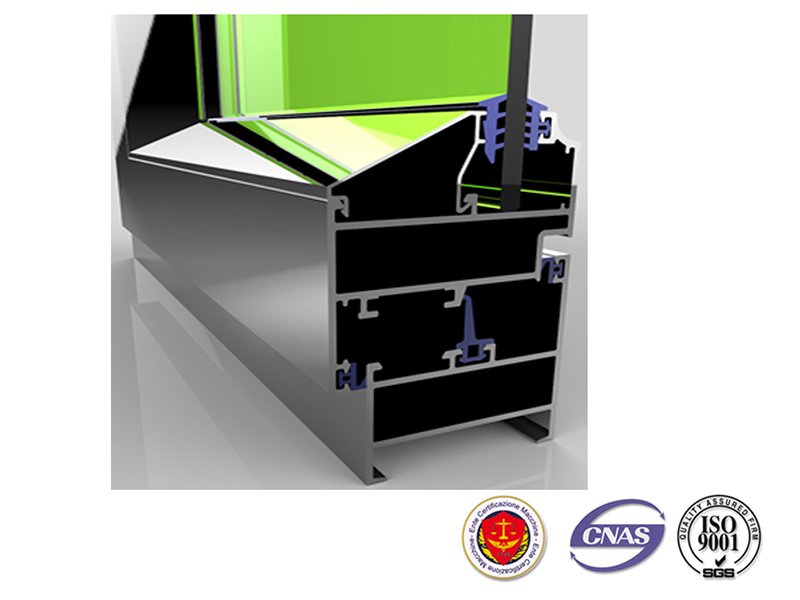

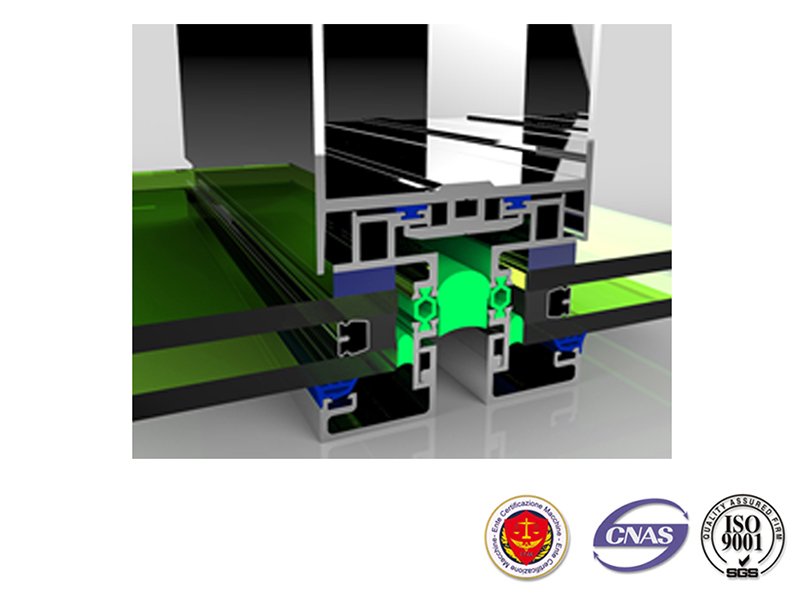

for window and door seal

Place of Origin:

foshan, china

Brand Name:

meirun, 3h, hehe,hehexin

Product type:

extrusion

Package:

100m/paper roll

Carton:

2 rolls/ctn

Serive temperature:

-30°c to 90°c

Certificate:

iso9001:2008 / astm

Size:

as per drawing

Hardness:

70±5

Name:

reformative pvc-frame sash strip

Item code:

b310b

Material:

reformative pvc-frame

Supplier Info.

Registration Date:

2006

Country / Region:

guangdong / China

City:

foshan

Main Products:

epdm rubber seal,epdm rubber,epdm sealing strip

Product Detail

/ Product description

Door frame rubber strip are used to seal gaps at door perimeters. By sealing the gaps along the door frame you can significantly cut down on the infiltration of sound, light, moisture, fire and smoke.

The Characteristic of PVC

/ Car tape real picture

/ Product application

/ Product Material

Sealing Rubber Strip Specification

| Characteristics | PVC | |

| Basic Characteristics | Shore A Hardness | 65±5,70±5,75±5,80±5 |

| Tensile-strength (Mpa) | ≥5.0 | |

| Tensile elongation (%) | ≥250 | |

| Compression Set (100℃*22h)(%) | — — | |

| Heat Aging(100℃*72h) (Tensile-strength and Tensile Elongation Variation (%)) | <15,<30 | |

| Heat Aging(100℃*168h) (Tensile-strength and Tensile Elongation Variation(%) ) | — — | |

| Weight Loss on Heating(%) | ≤3.0 | |

| Low Temperature Brittleness(-20℃) | Pass | |

| Low Temperature Brittleness(-40℃) | — — | |

| Product Performance | Usage Temperature(℃) | -20℃~100℃ |

| Flame Retardant | N/A | |

| Ozone Proof | Normal | |

| Storage Life(Year) | 5-7 | |

| Product Technics | Forming Method | Extrusion Molding |

| Corner Joint Menthods | Heat Weld | |

| Color | Multi-color | |

/ production process

1. Mixing

Weighting-Mixing-Oping mill-Cooling

-Mixing+Opening mill

-Cooling

2.Extrusion

High-temperature setting-Micro vulcanization-Hot vulcanization-Cooling

High-temperature setting

Micro vulcanization

-Hot vulcanization(HAV1)

-Hot vulcanization(HAV2)

-Hot vulcanization(HAV3)

cooling

3.Testing

-testing

4.Packaging

-packaging

/ Product design

Contact

Supplier

Contact us

Tell us your Buying Requirements

You Might Also Like