Semi automatic 1 gallon water bottling machine blow mold machine

High output:90-120bph

CE standard

Energy saving

The lowest price

Brief introduction:

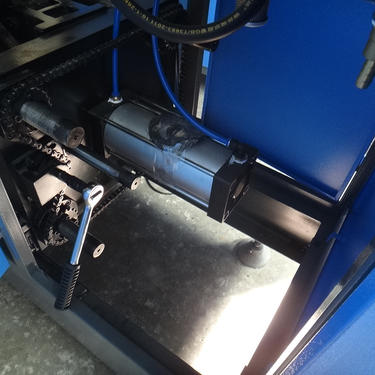

JND-90 semi-auto stretch blow molding machine is specially designed to produce 3-6 gallon bottle and 25L wide mouth jar. Its max output is up to 90 BPH for 5-gallon bottle and even could reach 120 bottles per hour in certain case.

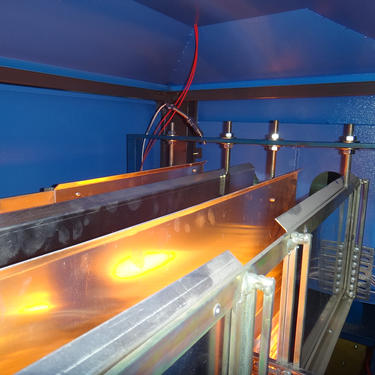

JND-90 consists of main unit and rotary infrared heater. The ordinary quartz lamp cannot heat preform ideally because the preform wall is excessively thick. The infrared heater with high penetrative force can heat the inside and outside of preform simultaneously and keep preform in even heating, therefore high shaping quality.

What an operator should do during production is just to put heated preform into the blow mold and press the switch, and then computer will take care of the whole procedure.

Main technical standards:

General Information | JND-880 | JND-90 |

Clamping Force | 120KN | 30T |

Clamping Stroke | 330mm | 330mm |

Max. Stretching Stroke | 550mm | 450mm |

Bottom Moving Stroke | 70mm | -- |

Number of Cavities | 1 Cavity | 1 Cavity |

Theoretical Output | 400BPH | 90BPH |

Max. Mould Thickness | 250mm | 380mm |

Space Between Tie Bars | 340*540mm | 480*550mm |

Electrical System |

| |

Voltage Standard | AC 380V/50HZ | |

Number of Heating Zone | 2 Sections | 2 Sections |

Total Power(Full Loaded) | 15kw | 15kw |

Container | ||

Max. Container Volume | 0.1-5L | 25L |

Neck Diameter Range | 65mm | 65mm |

Max. Container Diameter | 400mm | 330mm |

Max. Container Height | 550mm | 550mm |

Auxiliary System | ||

Low Air compressor | 8-10Bar | |

High Air compressor | 30Bar | |

Air Dryer | 2.0/30 | |

Dimension & Weight (L×W×H) | ||

Blow molding machine | 2600*1900*1950mm | 1550*820*2000mm |

Preform Autoloader | -- | 2520*680*1550mm |

Net Weight | 0.94Ton | 1.4Ton |

ShenZhen J&D Drinking Water Equipment Co., Ltd. is China's leading manufacturer of bottling equipment and supply the global market with a complete range of bottling equipment and accessories.

J&D Water can supply the following equipment:

* water dispensers, water filtration systems and all associated equipment required for a bottling factory including bottle blowing, labeling and packaging equipment.

*3000-36000BPH mineral water & pure water processing and filling lines

Which equipment do you need?

Bottled beverage filling machine, 5 gallon bottle water filling machine, 3L-10L bottle filling machine or cup filling machine

Requirements of filling container and capacity.

Bottle, barrel, cup.

Which label do you want to use?

The labeling machines include: hot melt glue labeling machine, cold glue labeling machine, self-adhesive sticker bottle labeling machine and automatic shrink sleeve labeling machine.

What packing method do you want to choose?

The packing machines include: film packing machine and carton packing machine.

1, the guarantee of our machines is at least two years, also we will send 3% of sales value as spare parts along with the machines free of charge, the parts will be enough for at least 3 years for the normal operation of machines.

2, we can train your engineers in our factory free of charge. It means you can send your engineers to our factory to study and training, we have rich experiences for the training, it is the good way to make sure that you can operate and maintain our machines successfully and for long term normal use.

3, we will offer you detail manual books for our machines, also we will make one Video CD to show you how to install and maintain the machines, the CD is the movie for the machines, it will be the great references for you to maintain the machines for the long time.

4,another way is that we can send our engineers to your factory to install the machines and train your engineers, we think it is the best way to help you operate and maintain the machines. We have been doing the install jobs for our overseas customers for many years. In this way you need to pay for the travel costs for our engineers, because our initial quotes don’t include the travel costs.

5, All of the electrical parts in our machines are CE or TUV approved. We can offer you UL or CUL/CSA approved parts if you need for the North American markets. The good electrical parts are the guarantee for the good quality for our machines.

Any more information , pls feel free to contact us, we will contact you soon, and also welcome to visit us.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts