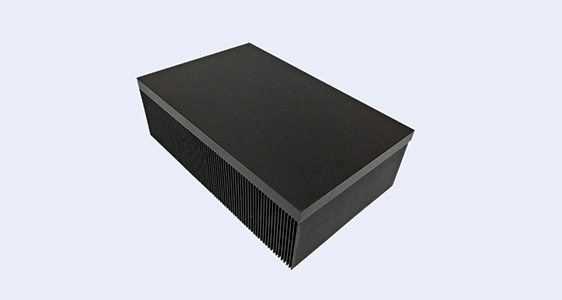

Skived Fin Heat Sink with black anodized From Lori

| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | Skived fin | Temper: | T3-T8 |

| Material: | AL6063 | Shape: | Square |

| Packing: | Paper carton with wooden pallet | Brand Name: | LORI |

| Application: | High power devices | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | LR0114 | Tolerance: | 0.05 mm |

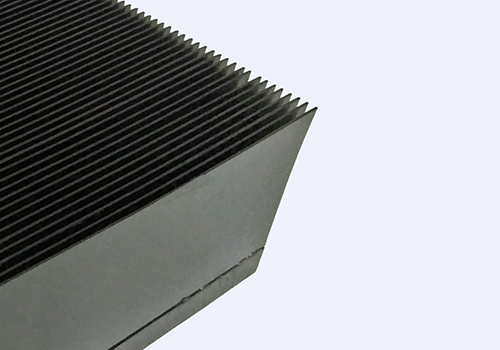

| Finish: | Andoized | Fin thickness: | 0.25 --2 mm |

| Extra process: | CNC Machining | Size: | 350*180*40 mm |

| Applied Field: | Telecommunication, UPS, inverters, controllers, wind power converters, and SVG | ||

AL1060 / AL 6063/ CU1100 Process parameter: | |||

Skived fin heatsink

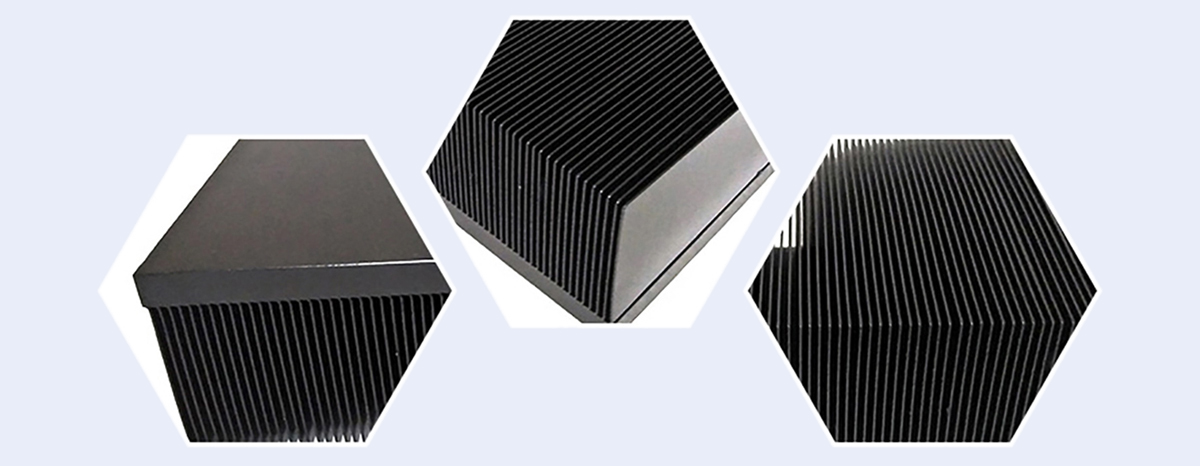

This Skived Fin heat sink made of aluminum 6063 and the size is 350*180*40 mm. The skived fin heat sink surface treatment is black anodized. it have some advantages as following.

Enables Solid Copper Solutions

Save cost on tooling , because skived fin heat sink do not need made tooling, each fin is cut using a special tool by skivied machine.

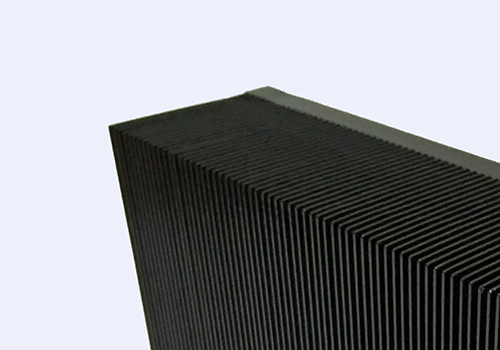

Alternative to extruded heat sink, when need the high desity heat sink which can not get by the extrusion techonoly.

Improved Thermal Performance, the skived fin heat sink made of pure aluminum and the fin and base are one piece.

Applied to Communication, UPS, inverter, controller, wind power converter, SVG telecommunication.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.

Contact

Supplier