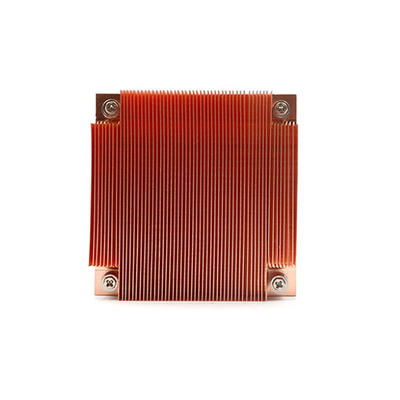

Skiving Heatsink With Heatpipe

| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | Skiving+ soldering+ CNC Machining | Temper: | T3-T8 |

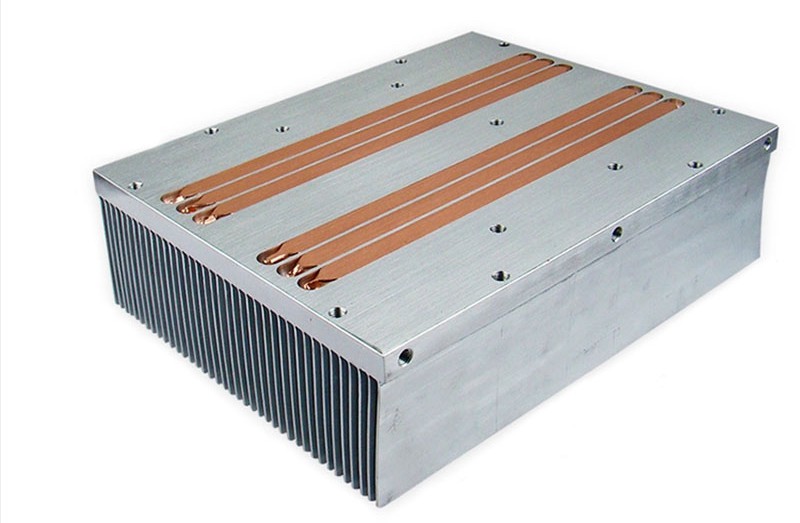

| Material: | Aluminum + Heat pipe | Shape: | Square |

| Packing: | Paper carton with wooden pallet | Brand Name: | LORI |

| Application: | Cooling high-power devices | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | LR0167 | Tolerance: | 0.05 mm |

| Finish: | Passivation | Fin thickness: | 0.25 --2 mm |

| Design | Custom made | Size: | 200x159x59mm |

| Applied Field: | Telecommunication, UPS, inverters, controllers, wind power converters, and SVG | ||

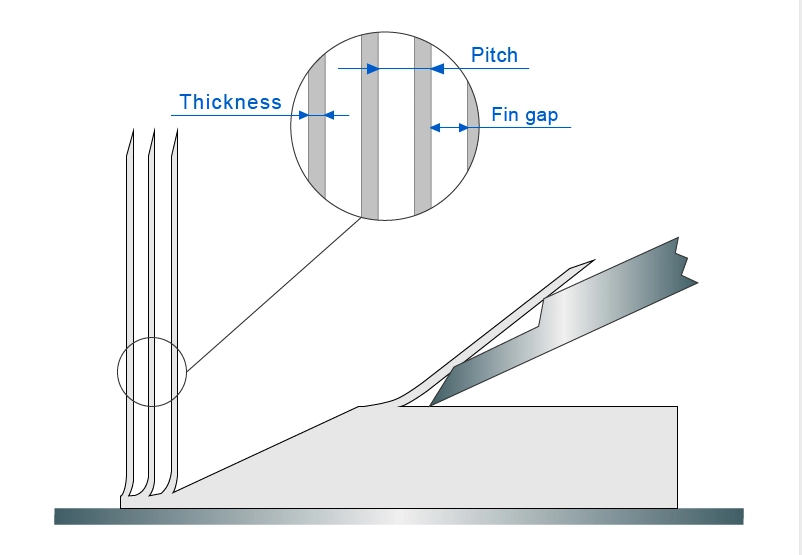

Skiving heatsink Process parameter: Materials: Copper (C11000) or Aluminum (6063) Base thickness: 1~30 mm Fin length: <550 mm Fin height: <120 mm Recommended fin height: <50 mm Recommended fin thickness: 0.3-0.6 mm | |||

Product Features

Skiving heatsink with heatpipe featues and benifits as below

Skiving heat sink use a special sheet, with the dedicated chipping equipment(skiving precision cutting technology) to required chainrings, Ultra-small spacing, Multiple ultra-high heat sink body structure, heat sink efficiency is two times than traditional style due to the chainrings combined with base, and high purity materials.

1. Skiving technology leading the heat innovation innovation high density ,high thermal performance, high aspect ratio, excellent performance.

2. Skiving heatsink soldering with heatpipe, it owned both the advantage of Al Material and heat pipe ---Good thermal conductivity

3. Customized design size is 200*159*59mm, other customized size is accepted.

4. Factory price and Industrial high quality heat sink.

Skiving heatsink with heatpipe has heat stable, secure, reliable, and can effectively protect the heating elements extend its life.

The main products of skiving heatsink with heatpipe are: high power heatsink, IGBT heatsink, electronic components / chips / CPU cooler, different power levels to meet the cooling needs, to achieve the best cost-effective price.

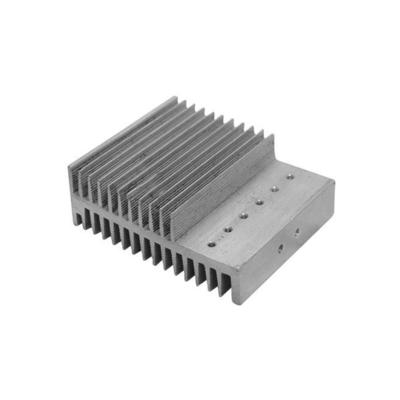

Skiving heatsink: When passing through the machine, slabs are skived in a specific angle so as to form and bend the fins. With the repetitive cutting, it forms consistent gaps and structures and can be used for cooling high-power devices under air-cooled conditions. This process can enhance 8~15% of the cooling capacity as compared to the stitched fin process. Leading the heat innovation innovation high density ,high performance, high aspect ratio, excellent performance.

Skiving heatsink's benifits:

1. Integrated manufacturing, no welding and mold opening; 2. The thickness and spacing of fin can be made thinner and denser; 3. The thermal conductivity is superior to the traditional extrusion and bonded fin process.

Skiving heat sink Application are:

Servers, workstation& Tower desktop solution, Power Supply, CPU, Telecommunication, Wireless Network, Security, Industrial, Power, New Energy, military, Laser, Aerospace, Automobile, Machinery, Medical, large inverter, Telecommunications transmitters devices.

Contact

Supplier