Low friction coefficient; no stick-slip effect.

Possible increase in extrusion gaps.

Excellent extrusion resistance even during pressure peaks.

Excellent abrasion resistanceAssembled by deformation.

SPGW-Excavator Parts Hydraulic Piston Compact Seal

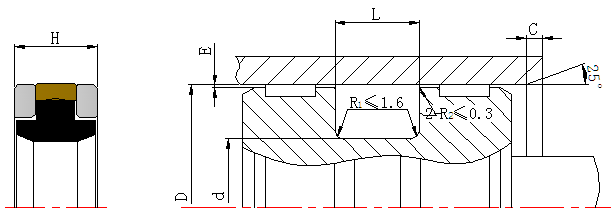

The common compact seal SPGW is made of a sealing ring, an O-ring and back up ring. Sealing ring material is generally filled with PTFE; the O-ring is made of nitrile rubber (NBR). ) or fluororubber (FKM); the back up ring is made of polyoxymethylene (POM) material. The combined seal SPGW has good dynamic and static sealing performance, low friction coefficient, no creeping at startup, and more importantly, stable operation.

SPGW is a high performance double acting compact piston seal consisting of a dynamic bronze filled PTFE friction ring, a profiled preloaded NBR ring and two POM back up rings. It has excellent resistance to leakage, extrusion and friction. SPGW compact seal is especially suitable for long-distance travel. When used in a variety of fluids and high temperatures, it is suitable for wider piston spacing. By stacking, the SPGW compact seals form a compact structure and excellent performance, mounted in a single piston groove. Its geometry gives it overall stability, wear resistance, tightness, low friction and long life without maintenance. Due to the initial shrinkage range set, the seal has good sealing properties at low pressure. When the pressure is raised, the sealing performance remains good because the elastomer exerts a stress on the combined seal ring, thereby converting the axial force from system pressure to radial compression. Suitable for overloaded nylon shielding rings. Designed to protect seals from crushing damage, it meets the requirements of a wide range of hydraulic cylinders.

Advantages

◆◆ PTFE, nbr/fkm rubber,POM

| Material description | PTFE filled Bronze, PTFE filled carbon fiber and MoS2, PTFE filled Graphite, PTFE filled PI, PTFE filled Ekonol, PU and so on. |

| Available Color | Black, green, coffee, white, red, blue, gold and so on |

| Material Strength | SPGW seals can be used under high pressure conditions. It has excellent leak resistance, extrusion resistance and wear resistance. |

| temperature | -40~+160℃ |

| speed | ≤1.50m/s |

| pressure | ≤50MPa |

| Applied device | Hydraulic equipment / standard cylinder / machine tool / injection machine / hydraulic machine, etc. |

◆◆ PTFE, nbr/fkm rubber,POM

| |||||||||||||

| Technical Data | |||||||||||||

| Pressure | Temperature | Sliding speed | Medium | ||||||||||

| Standard | ≤50 MPa | -40…+160 ℃ | ≤1.5 m/s | Minderal oil based hydraulic fluids, barely flammable hydraulic fluids,water,air and others. | |||||||||

| Material | |||||||||||||

| elastomer | slide ring | Backup ring | |||||||||||

| Standard | NBR/PU80 | Bronze | P0M | ||||||||||

| Standard (on request) | FKM | PTFE-carbon | PTFE | ||||||||||

| pressure | 160bar | 250bar | 400bar | 500bar | |||||||||

| Max Gap E | E≤1.0mm | E≤0.8mm | E≤0.6mm | E≤0.4mm | |||||||||

Order Example for standard version: | |||||||||||||

Diameter D=100mm | |||||||||||||

Order Code: SPGW 100*85*12.5 | |||||||||||||

Installation Dimension table based on Metric Size(mm) | |||||||||||||

| D H9 | d h9 | L+0.2 | H | C≥ | |||||||||

| 50~60 | D-14 | 9 | 8.5 | 4 | |||||||||

| 65~95 | D-15 | 11 | 10.5 | 4 | |||||||||

| 100~120 | D-15 | 12.5 | 12 | 4 | |||||||||

| 125~240 | D-23 | 16 | 15.5 | 6 | |||||||||

| 250~320 | D-28 | 17.5 | 17 | 7.5 | |||||||||

| Order List | |||||||||

| Order Number | D | d | H | h | Order Number | D | d | H | |

| SPGW 0500 | 50 | 36 | 9 | 8.5 | SPGW 1500 | 150 | 127 | 16 | |

| SPGW 0600 | 60 | 46 | 9 | 8.5 | SPGW 1600 | 160 | 137 | 16 | |

| SPGW 0650 | 65 | 50 | 11 | 10.5 | SPGW 1700 | 170 | 147 | 16 | |

| SPGW 0700 | 70 | 55 | 11 | 10.5 | SPGW 1800 | 180 | 157 | 16 | |

| SPGW 0750 | 75 | 60 | 11 | 10.5 | SPGW 1850 | 185 | 162 | 16 | |

| SPGW 0800 | 80 | 65 | 11 | 10.5 | SPGW 1900 | 190 | 167 | 16 | |

| SPGW 0850 | 85 | 70 | 11 | 10.5 | SPGW 2000 | 200 | 177 | 16 | |

| SPGW 0900 | 90 | 75 | 11 | 10.5 | SPGW 2100 | 210 | 187 | 16 | |

| SPGW 0950 | 95 | 80 | 11 | 10.5 | SPGW 2200 | 220 | 197 | 16 | |

| SPGW 1000 | 100 | 85 | 12.5 | 12 | SPGW 2250 | 225 | 202 | 16 | |

| SPGW 1050 | 105 | 90 | 12.5 | 12 | SPGW 2300 | 230 | 207 | 16 | |

| SPGW 1100 | 110 | 95 | 12.5 | 12 | SPGW 2400 | 240 | 217 | 16 | |

| SPGW 1150 | 115 | 100 | 12.5 | 12 | SPGW 2500 | 250 | 222 | 17.5 | |

| SPGW 1200 | 120 | 105 | 16 | 15.5 | SPGW 2600 | 260 | 232 | 17.5 | |

| SPGW 1250 | 125 | 102 | 16 | 15.5 | SPGW 2700 | 270 | 242 | 17.5 | |

| SPGW 1300 | 130 | 107 | 16 | 15.5 | SPGW 2800 | 280 | 252 | 17.5 | |

| SPGW 1350 | 135 | 112 | 16 | 15.5 | SPGW 3000 | 300 | 272 | 17.5 | |

| SPGW 1400 | 140 | 117 | 16 | 15.5 | SPGW 3200 | 320 | 292 | 17.5 | |

| SPGW 1450 | 145 | 122 | 16 | 15.5 | |||||

Contact

Supplier