UAV products for Intelligent Industrial

OUR COMPANY

It is our mission to offer you bread with love. Bread, in its pure original formula, making it available for everyone's enjoyment. From antiquity,bread has been known as the epitome of life and human society. It's history can be traced back for thousands of years to the ancient Egyptians, Romans and Greeks.

Talk about the products

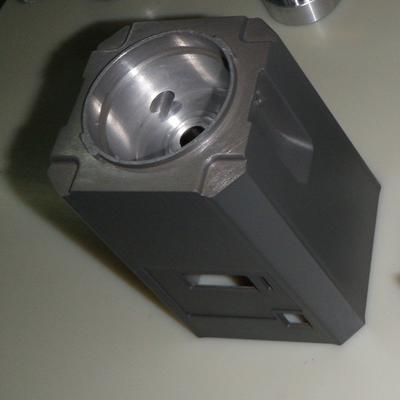

Gaojie modeling and prototyping are widely used in industrial fields of our production model, new product

development model and small batch production. This is before the customer open mold, small batch production

of UAV parts.

Talk about the Client

Intelligent Industrial Development Co., Ltd.,They are the production and development of UAV, small batch production and provide products to the customers. They're making, we understand that the UAV quality requirements is relatively high, the precision is relatively more stringent control, and delivery time is urgent, we must guarantee the quantity and quality of finish, can according to customer satisfaction.

What's the Challenges

It is not difficult to imagine the UAV control and requirement of the weight, but the size is not small, so the product draw wall thickness is very small, even less than the minimum 1mm, silicone mold making, is because it is not easy to feed and scrap, so we have to pay special attention to and control, and later the appropriate repair.

3D Printing The Model

We made the master models using stereolithography (SLA), a 3D printing technology.The main mode need to be carefully done, because the silicon die to do a good job, even tiny details surface transfer to any subsequent copies.

Making the mold

We made a silicon mold according to the template to form a master pattern using the customer's 3D product design.

Once the master mold was created we could start the vacuum casting replica.The typical mold is a good high fidelity replica of around twenty, ideal for rapid prototyping with minimal cost.

Contact

Supplier