Ultra-thin Silicon Steel Core

Conventional silicon steels are widely used for electrical power apparatus, electrical components of industrial products, and home electronics. However, most silicon steel strips are thicker than 0.20mm and only applied to apparatus operated at industrial frequencies.

The thin silicon steel strips are suitable for being used at higher frequencies. The thickness of the silicon steel strips haVE been reduced to the world's thinnest level, reducing the core loss caused by eddy currents. Combined with the insulation coating technology, the lamination factor is improved.

The thin silicon steel strips improve energy consumption and reduce size in high-frequency reactors, transformers, and motors.

The thin silicon steel strips reduce cost and improve the equipment performance at high frequencies.

Characteristics

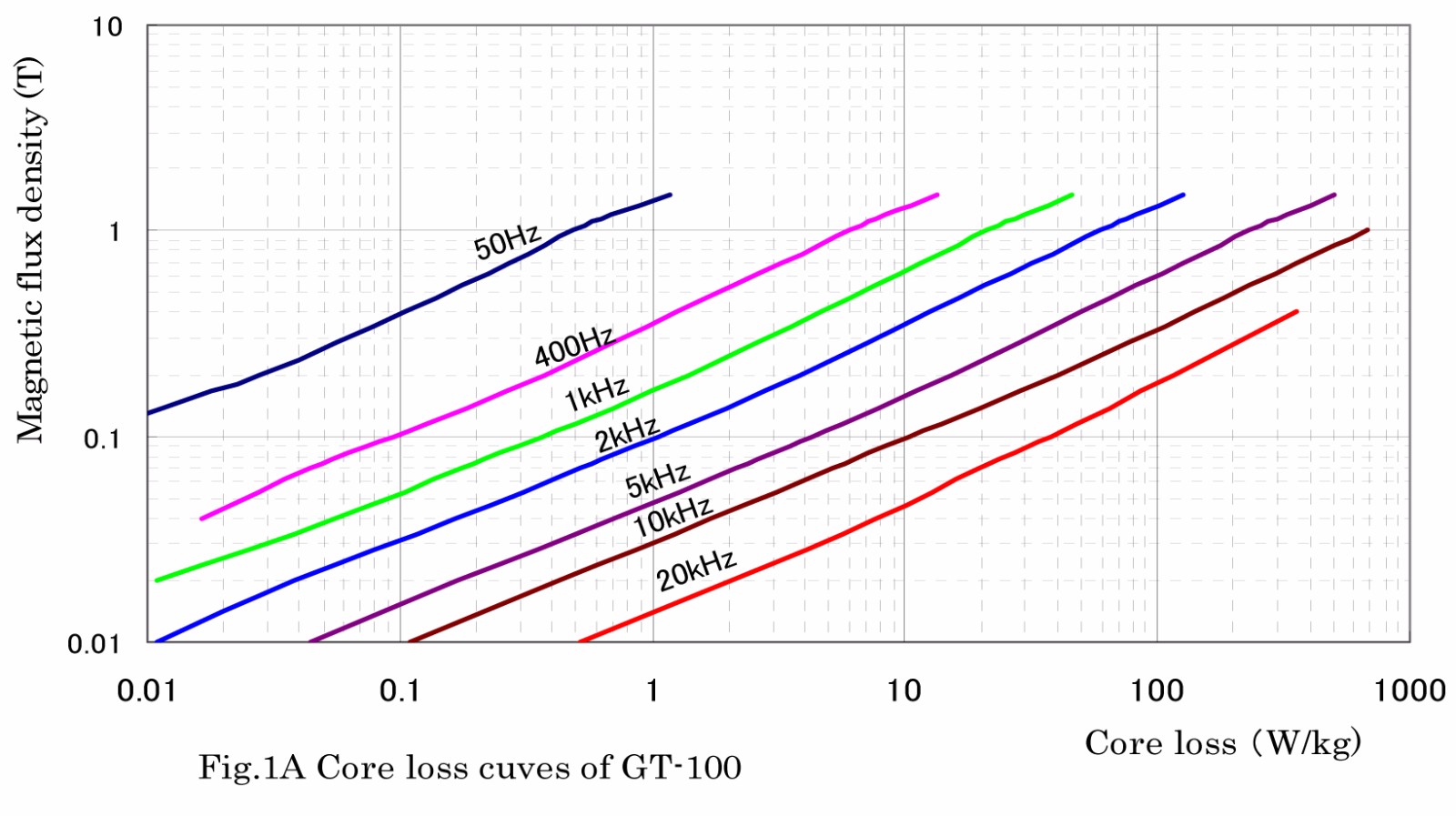

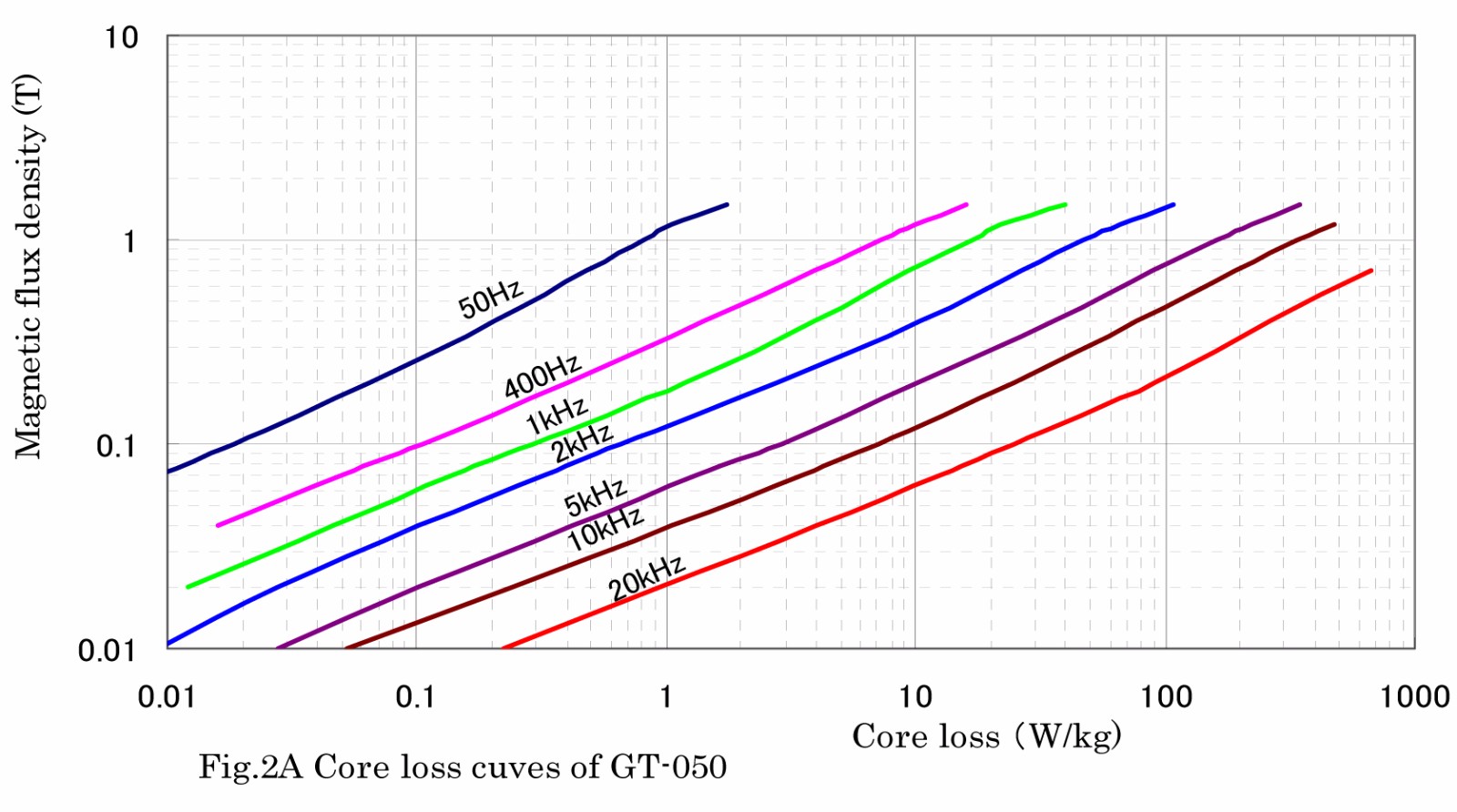

■ Low Core Loss

Low core loss at high frequencies improves equipment efficiency and reduce energy consumption of reactors and transformers.

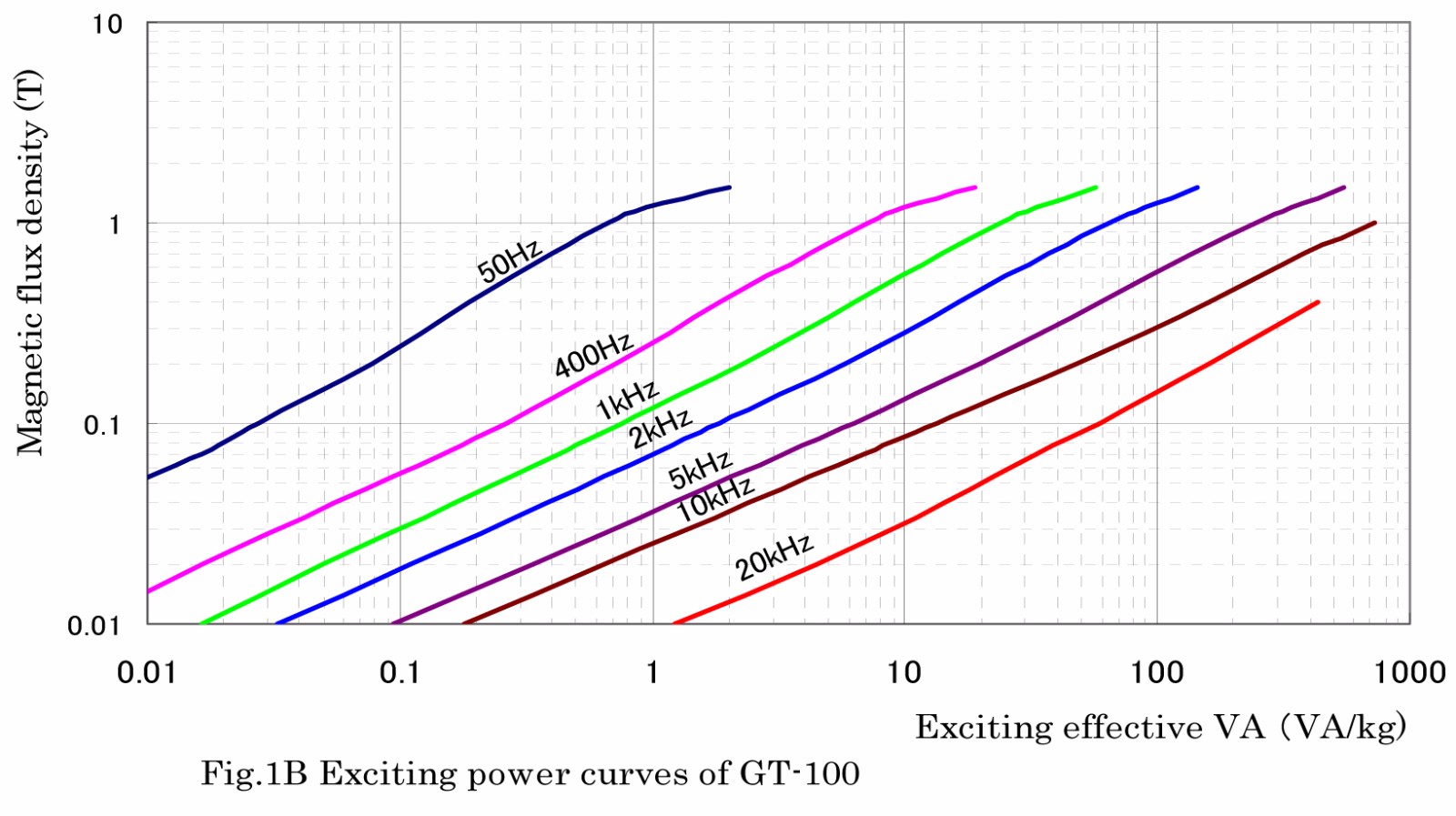

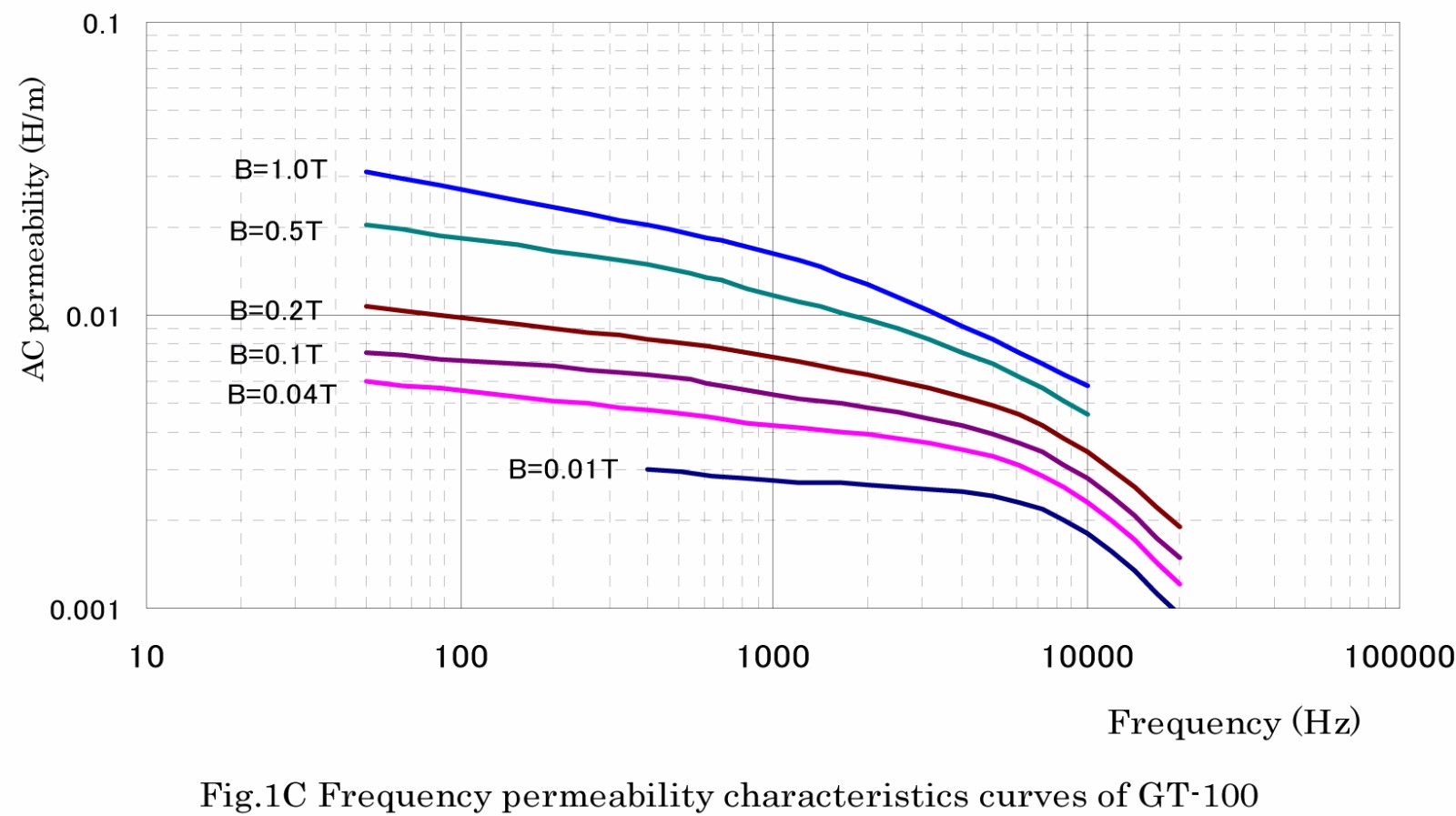

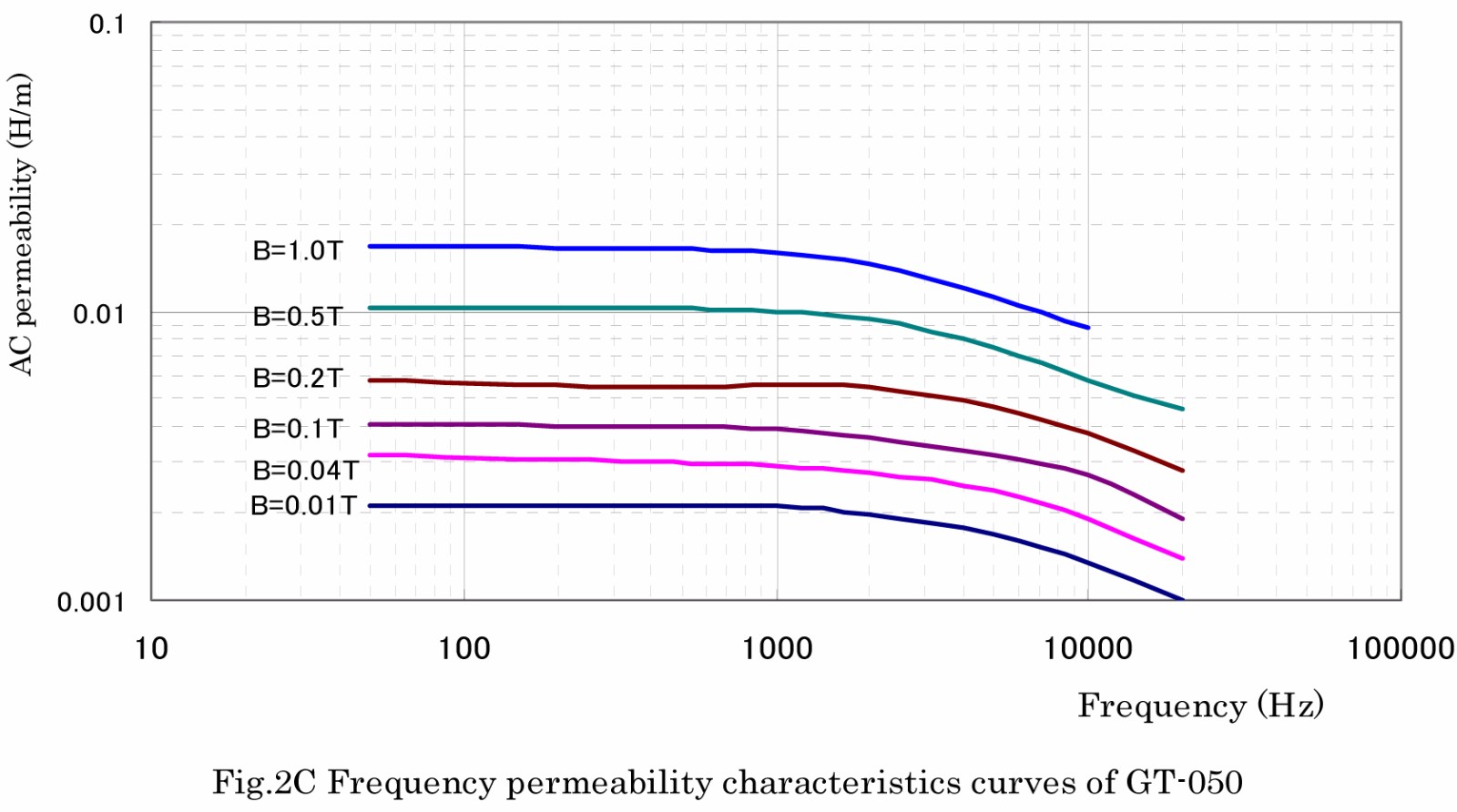

■ High Permeability

For shields applications.

■ High Saturation Flux Density

For downsized high frequency reactors and transformers.

■ Excellent insulation coating

Excellent insulation property enables ideal stress relief annealing (results).

Magnetic Parameters

| Table 1 Core loss properties | ||||||||

| Grade | Core loss (W/K | |||||||

| W15/50 | W15/100 | W10/400 | W10/1000 | W5/2000 | W2/5000 | W1/10000 | W0.5/20000 | |

| GT-100 | 1.2 | 3.0 | 6.1 | 21.3 | 18.0 | 15.2 | 10.4 | 13.0 |

| GT-050 | 1.7 | 5.0 | 7.3 | 17. | 13.0 | 10.2 | 7.1 | 5.3 |

| Table 2 Permeability and magnetic flux density properties | ||||||||

| Grade | Alternating permeability x 10-3 (H/m) | Magnetic flux density (T) | ||||||

| μ10/400 | μ10/1000 | μ5/2000 | μ1/10000 | μ0.5/20000 | B8 | B25 | B50 | |

| GT-100 | 20.4 | 16.2 | 9.6 | 2.8 | 1.2 | 1.82 | --- | --- |

| GT-050 | 16.6 | 16.0 | 9.9 | 2.7 | 1.5 | 1.75 | --- | --- |

Note: The specimens are taken from the strips parallel to the rolling direction. The measurements are in accordance with JIS C 2550 after stress relief annealing.

| Table 3 Mechanical and electric properties | ||||||

| Grade | Density (g/cm3) | Space factor (%) | Tensile strength (N/mm2) | Elongation (%) | Hardness (Hv) | Specific resistance (μΩcm) |

| GT-100 | 7.65 | 93 | 420 | 9 | 202*2 | 48 |

| GT-050 | 7.65 | 90 | 387 | 11 | 179*2 | 48 |

Note: 1. Tensile strength and elongation are measured parallel to the rolling direction.

2. Hardness are measured by *1: H;0.5Kg, *2: H;0.3Kg, *3: H;0.1Kg.

| Table 4 Comparison of properties between various magnetic materials | ||||

| Material | Magnetic flux density B8 (T) | DC max relative permeability μm | Core loss W1/20000 (W/Kg) | Specific resistance (μΩm) |

| GT-100 | 1.82 | 24,000 | 35 | 0.48 |

| GT-050 | 1.75 | 14,000 | 51 | 0.48 |

| High silicon steel (0.1t) | 1.29 | 23,000 | 31 | 0.82 |

| Amorphous | 1.56 | 300,000 | 6 | 1.30 |

| Nanocrystalline | 1.23 | 70,000 | 4 | 0.01 |

| Dust core (Sendust) | 0.65 | 150 | 62 | >10,000 |

| Ferrite (Mn-Zn) | 0.45 | 3,500 | 3 | >100,000 |

Magnetization Curves

■ GT-100

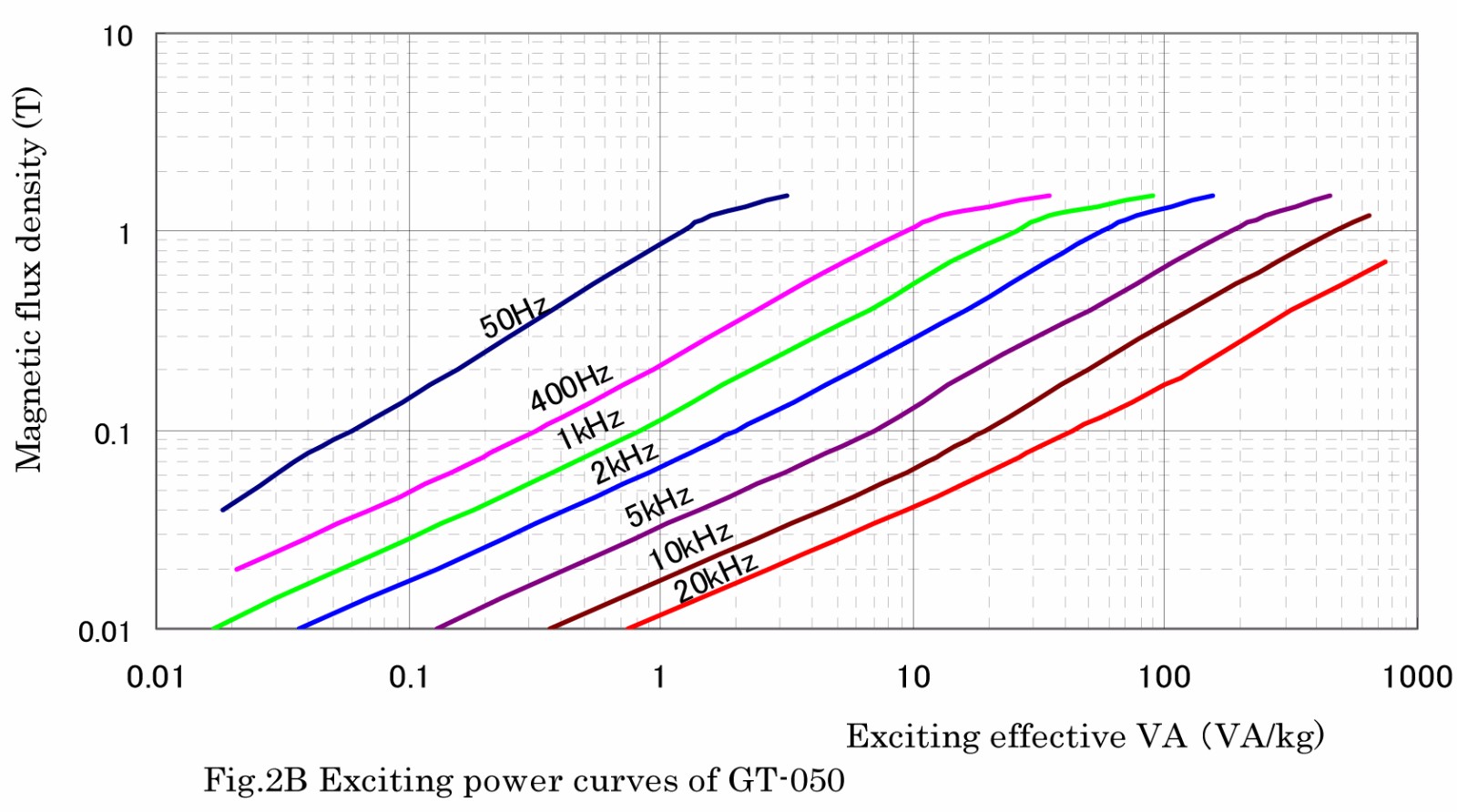

■ GT-050

Applications

Material: Imported Japanese 0.05mm, 0.10mm oriented thin-gauge silicon steels.

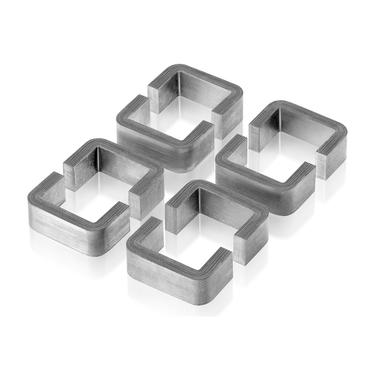

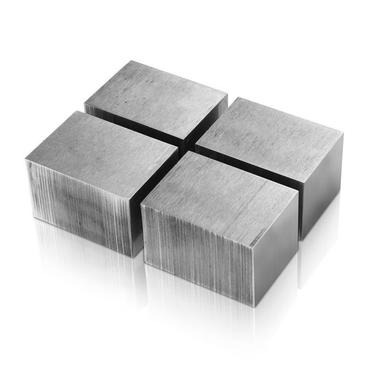

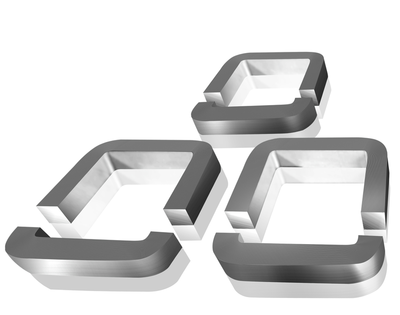

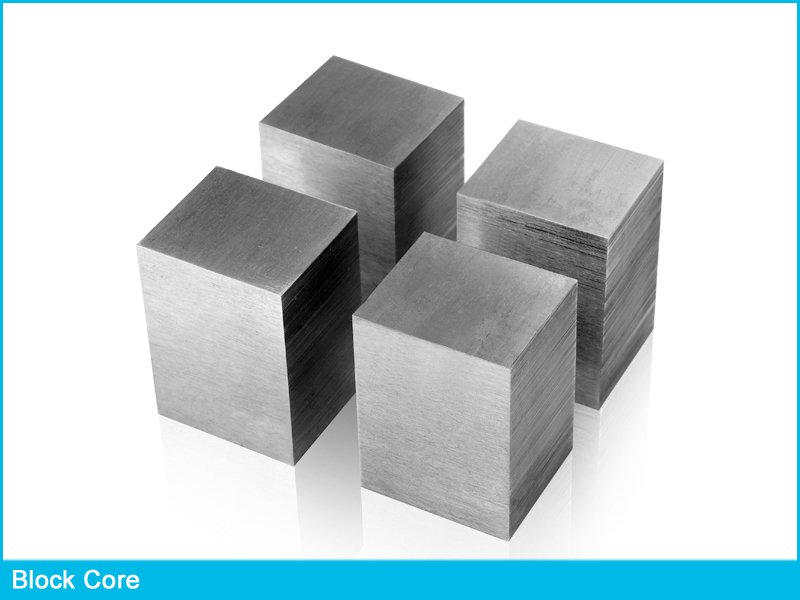

Features: NICORE produces tape wound cores, block cores, U-cores and other special cores with high quality steels according to customers requirements.

Contact

Supplier