Fireproof

Acid and alkali resistance

Toughness

Weather resistance

Low noise

Portability

Environmental protection

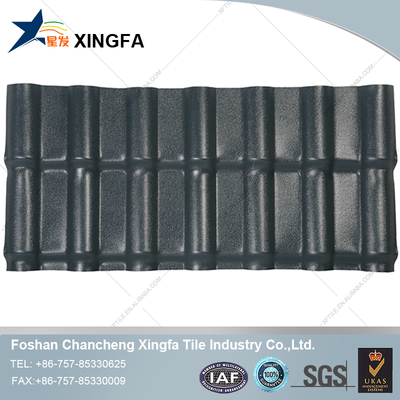

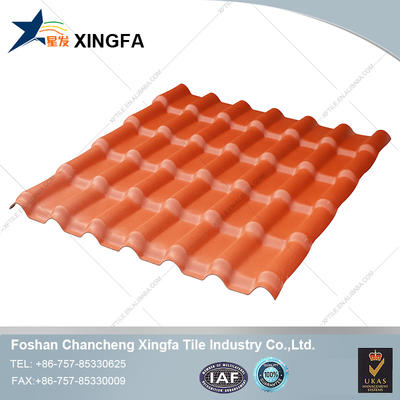

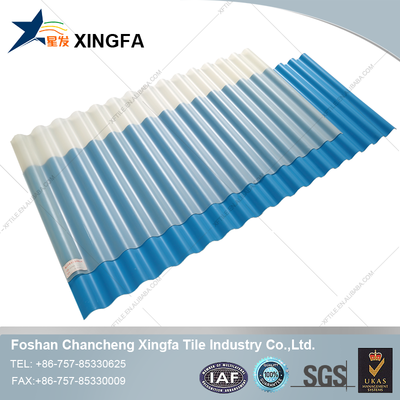

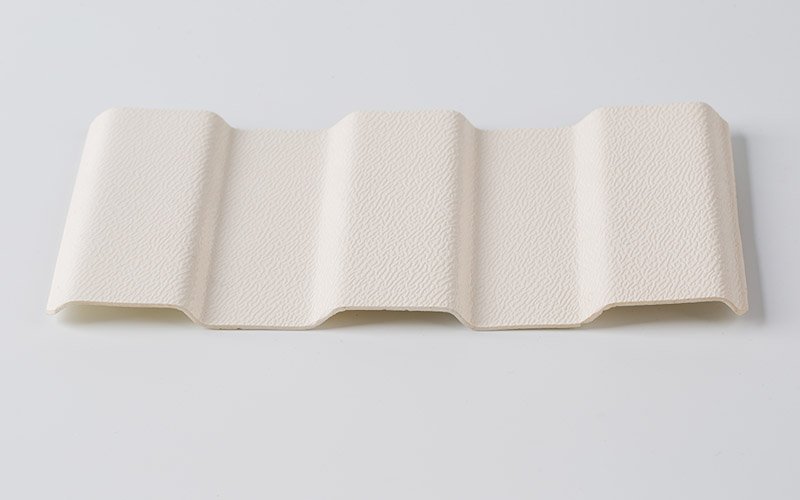

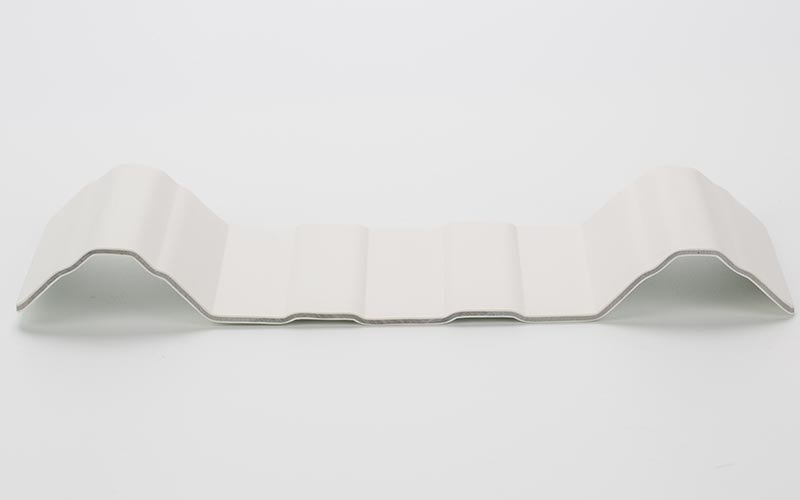

UPVC low wave roof sheet T900

UPVC low wave roof sheet

It is made of main raw material of PVC resin supplemented with anti-UV additive ,and made by scientific formula and unique process technology. It is occupied with good fire resistance,weather resistance and electrical insulation,which is an excellent anti-corrosion material. Provide the quality guarantee for 10 years.

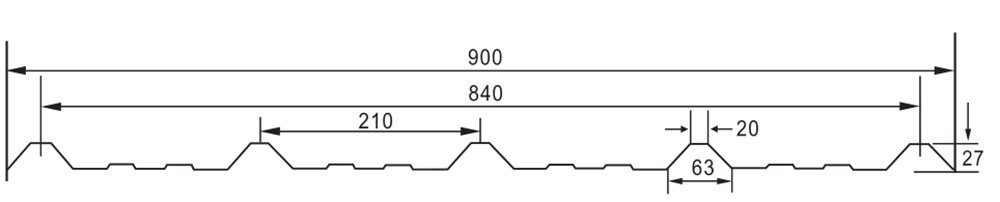

T900 Specification

Model | T900 |

Width | 900mm |

Efficient width | 840mm |

Thickness | 1.5mm,2.0mm,2.5mm,3.0mm |

Length | Customized (20'container 5.8 meter, 40'container 11.8 meter) |

Applications | factory roof, warehouse roof, wall panel etc... |

Surface finishing | ASA coated,Embossed type,standard type. |

Layer | Single layer, Three layers, Four layers |

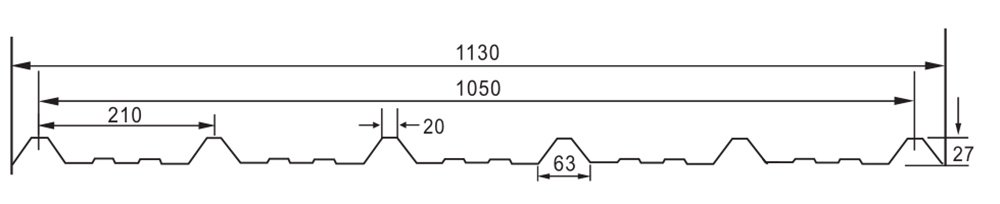

T1130 Specification

Model | T1130 |

Width | 1130mm |

Efficient width | 1050mm |

Thickness | 1.5mm,2.0mm,2.5mm,3.0mm |

Length | Customized (20'container 5.8 meter, 40'container 11.8 meter) |

Applications | factory roof, warehouse roof, wall panel etc... |

Surface finishing | ASA coated,Embossed type,standard type. |

Layer | Single layer, Three layers, Four layers |

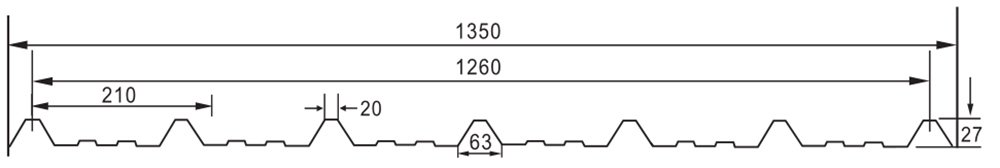

T1350 Specification

Model | T1350 |

Width | 1350mm |

Efficient width | 1260mm |

Thickness | 1.5mm,2.0mm,2.5mm,3.0mm |

Length | Customized (20'container 5.8 meter, 40'container 11.8 meter) |

Applications | factory roof, warehouse roof, wall panel etc... |

Surface finishing | ASA coated,Embossed type,standard type. |

Layer | Single layer, Three layers, Four layers |

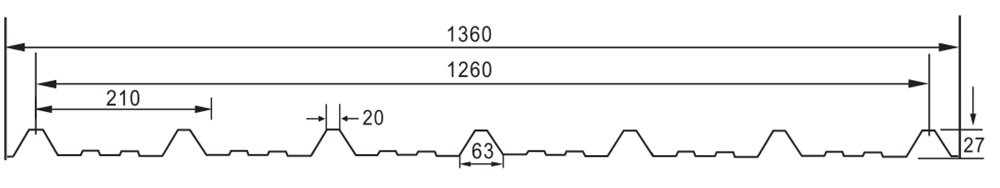

T1360 Specification

Model | T1360 |

Width | 1360mm |

Efficient width | 1260mm |

Thickness | 1.5mm,2.0mm,2.5mm,3.0mm |

Length | Customized (20'container 5.8 meter, 40'container 11.8 meter) |

Applications | factory roof, warehouse roof, wall panel etc... |

Surface finishing | ASA coated,Embossed type,standard type. |

Layer | Single layer, Three layers, Four layers |

900 size

1130 size

1350 size

1360 size

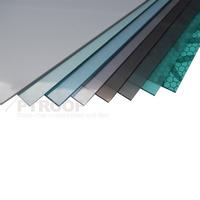

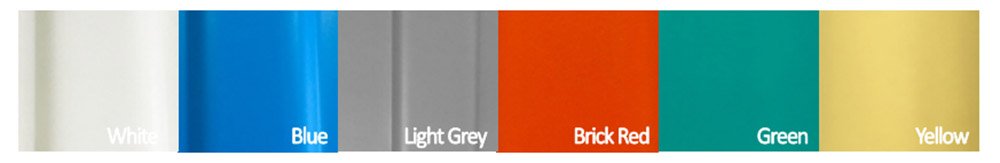

UPVC roof color

UPVC TEST REPORT

Num. | Test item | Test method | The test condition | Test result |

1 | Tensile strength | ISO 527-1:2012 & ISO 527 -2:2012 | Testing speed: 50mm/min | 23.1 Mpa |

2 | Flexural strength | ISO 178:2010/Amd.1:2013 Method A | Test speed: 1mm/min | 50.9 Mpa |

3 | Impact Resistance | With reference to GB/T 8814-2004 Section 5.7, Section 6.7 and client’s requirement | -10°C, 1h | Number of specimen failures: 0 |

4 | Vicat Softening Temperature | ISO 306:2013 Method B 50 | Rate of temperature: 50K/h | 77.0°C |

5 | Effects of liquid chemicals | ISO 175:2010 | Temperature: 23°C | No visual change |

ISO 175:2010 | Temperature: 23°C | Visual discoloring, but no other visual change | ||

ISO 175:2010 | Temperature: 23°C | No visual change | ||

6 | Light Ageing Test – Xenon-arc Exposure | ISO 4892-2:2013 cycle 4 & ISO 105-A02:1993/Cor.2:2005 & ASTM D2244– 15a | Exposure period: 1000h | Grey scale: 3 |

7 | Dimensional Stability | With reference to ASTM D1204-14 and client’s requirement | 100℃,60min→23±2℃, 50±5% RH, 60min | Direction of arrow: -0.6% |

NO. | Test item | Test method | Test condition | Result | |

1 | Tensile strength | ASTM D638-03 | Specimen: Type I | Before aging | 29.2 MPa |

After aging | 36.9MPa | ||||

2 | Flexural strength | ASTM D790-07 Procedure A and client’s requirement | 127x13.07x1.98mm | Before aging | 59.3MPa |

After aging | 62.8MPa | ||||

3 | Thermal Conductivity [W/(m·K)] | ASTM C518-04 | ---- | 0.08846 | |

4 | Coeffcient of Linear Thermal Expansion(μm/m·℃) | Rf.ASTM D696-03 | --- | 49.68 | |

5 | Vertical Burning | UL 94-1996REV.9:2006 section 8 | Specimen: 129x12.9x1.99mm | V-0 | |

6 | Oxygen Index | ASTM D2863-06a | Specimen:Type III | 36.3% | |

7 | Water absorption | ASTM D570-98(2005) | Drying :50℃,24h | 0.04% | |

8 | Vicat softening temperature | ASTM D1525-06 | Thickness: 3.92mm | 90.0℃ | |

9 | Heat deflection temperature | ASTM D648-07 Method B | Width: 12.83mm | 55.6℃ | |

10 | High temperature | Supplied by client | 60℃,6h | No visible change | |

11 | Impact resistance (Gardner impact) | ASTM D5420-04 | Statement of geometry: GE(striker:φ16.26mm) | Mean-failure energy 6J | |

12 | Low temperature resistance | Supplied by client | -35℃,6h | No visible change | |

13 | Chemical resistance | Supplied by client | 70% Ethanol Solution, (m/m),23℃,2h | No visible change | |

10% NaOH Solution, (m/m),23℃,2h | No visible change | ||||

Saturation NaCI Solution 23℃,2h | No visible change | ||||

14 | UV Exposure | ASTM G154-06 Cycle 1,ISO 105-A02:1993 | 8h UV at(60±3)℃ BPT, 0.89W/(m2·nm)@340nm 4h condensation at (50±3)℃ BPT Exposure period:1000h | Grey scale: 3 | |

About our Company

Contact

Supplier

Aluminum Composite Panels

Balustrades & Handrails

Bathroom

Boards

Building Glass

Ceilings

Countertops,Vanity Tops & Table Tops

Curtain Walls & Accessories

Decorative Films

Door & Window Accessories

Doors & Windows

Faucets, Mixers & Taps

Flooring & Accessories

Formwork

HVAC Systems & Parts

Kitchen

Ladders & Scaffoldings

Metal Building Materials

Mosaics

Plastic Building Materials

Quarry Stone & Slabs

Real Estate

Stairs & Stair Parts

Tiles & Accessories

Door, Window & Accessories

Stone