Vacuum Vulcanizing Shoes Shaping & Wrinkle Removing Machine YT-135A

Product model | YT-135A |

Product name | Vacuum Vulcanizing Shaping Machine |

Voltage | 380V |

Power | 4KW |

Function | Shoes shaping&wrinkle removing |

Machine Dimensions | 1040X850X1700(mm) |

Package Dimensions | 1240X980X1900(mm) |

Type | Semi-automatic |

N.W/G.W | 600/650KG |

Warranty | 1 Year |

Min Function

The machine is used to smooth shoes wrinkle and set the upper after lasting. It adopts German technology and features high efficiency, energy conservation and eco-friendliness.

1.Adopting CNC operating system, which is convenient, durable and easy to operate, and has maintenance prompt function.

2.The machine adopts auto-lifting cart design which is easy to operate and saves time and labor and improves working efficiency.

3. It adopts advanced German energy-saving system and closed vulcanizing system which are more energy efficient than traditional vulcanizing machine and can save more than 70% of the energy.

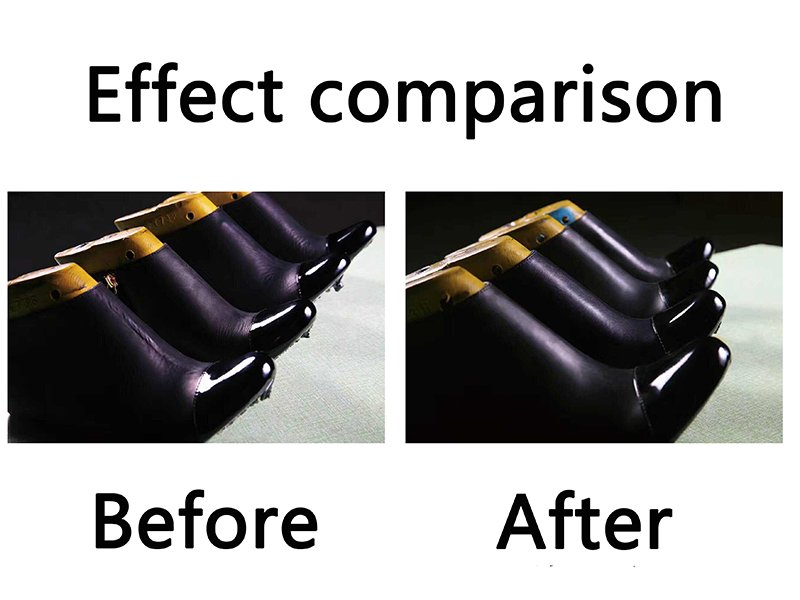

4. German two-cycle wrinkle-removing system is used. The wrinkle remove effect is excellent through vacuum shaping, and shoes will be more beautiful with these perfect detail processing.

5. Adopts all-round steam spraying device. The shoes are shaped after a series of procedures, including heating, softening, steaming, drying and vacuum shaping ,and the vamp fits better with last.

6. Fast setting speed and one case of shoes can be shaped within 12 minutes.

Contact

Supplier

Agriculture Machinery & Equipment

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts