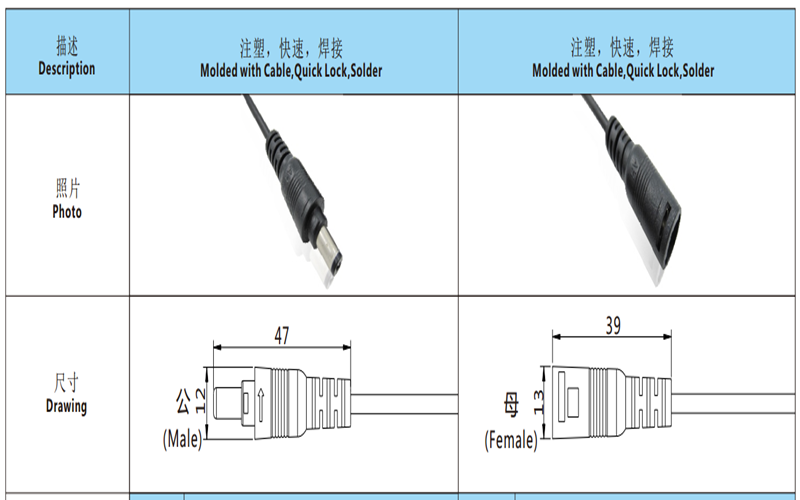

White Quick Lock 5.5*2.1 panel lighting dc power connector

Product application range (use):

Widely applicable to all kinds of high-power outdoor engineering connections, such as:

LED light strips, spotlighting, wall washing landscape lighting, billboard lighting, tunnel lighting, LED flood lighting, street lighting, open-air stage, display screen, etc., and the products can also be used along the coast, river, lake or underwater engineering, mining engineering.

Underground engineering and heating projects:

such as floor heating tiles, etc., solar water heater integration/ multi-body lithium battery solar light, solar wind power farm.

Working machinery:

such as intelligent spray machine, intelligent greenhouse blower, insecticidal lamp and various mechanical equipment. Also can be used in communications field such as subway, high-speed rail, car and international aerospace.

Product advantage:

The product is made from the same set of cord with the same appearance , but is different from the inside structure, for example:

Normally, the steps is cutting the cord- crimp terminal- molding- testing and then shipped. If various processes are not strengthened, it will be easy to cause problems such as high possibility of defective product and short product life during use time of customer. However, the problem is not existing in our products because our products are not only have beautiful appearance, but also have durable life.

Contact

Supplier