Zircon refractory ramming material for the glass melting pool below the bottom hot mullite lining

Zircon refractory ramming material for the glass melting pool below the bottom hot mullite lining

Product Description

Refractory material is a high proportion of granular materials and a very low proportion of the binder and other groups of distribution system, and even all of the grain, powder composition, to be beaten by the way of the construction of a strong.

In the form of a dry or semi dry loose shape, a compact structure is obtained by the strength of the refractory material, which is only heated to the sintering temperature, and the strength of the combined body can be obtained. After the stamping process, different heating methods can be adopted to promote the hardening or sintering of the mixture.

technical date

Ramming material | High alumina | Magnesia | Magnesia chrome | Alumina zirconia | |

Chemical Composition % | Al2O3 | 83 | 2.3 | 6 | 68 |

ZrO2 | 1.1 | 93(MgO) | 59(MgO) | 11 | |

Cr2O3 | - | - | 16 | - | |

Compressive strength MPa | 110°C | 38.5 | 62 | 43.5 | 26.5 |

1000°C | 47.6 | 54 | 25.8 | 42.6 | |

1600°C | 67.2 | - | 38.5 | 38.4 (1400°C) | |

Refractoriness under load °C |

4% | - | - | 1500 | 1340 |

Reheating linear change % |

1600°C | +0.60 | -0.15 (1600°C) | -0.60 | +0.93 (1400°C) |

Apparent porosity % | - | 14 | 13 | 23 | |

Bulk density g/cm3 | 2.70 | 2.95 | 2.70 | 2.70 | |

Features

1.Refractory material has high volume stability and compactness.

2.Refractory and refractory material with corrosion resistance.

3.Refractory and refractory material with insulation.

4.Refractory material has good plasticity.

5.Refractory pounding material thermal stability strong resistance to high temperature.

Applications

Refractory ramming material for ladle integral reach lining, liner of induction furnace, furnace tapping tank lining, and contact with hot metal liquid and slag high-temperature vessels is also used to middle and small blast furnace .

Product manufacture

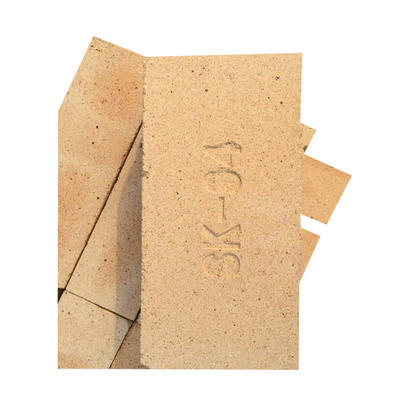

Each piece of high quality refractory bricks are from raw material to start .Clay refractory brick is a clay as the main raw material, through mud processing, molding, drying and roasting and. And then through the detection of detection equipment, to ensure that the quality of each brick, which is a batch of refractory brick process.

Production flow + quality inspection

Packaging & Shipping

packaging

1. woven bag packaging.

2. bag + pallets .

3. woven bag capacity have 25kg and 50kg.

4.pallets: 1*1m,0.93*0.93m .

5.can be packaged according to customer requirements.

Our Services

1.Give an answer within 8 hours.

2.Provide sapmples freely and price lists.

3.We provide the best after sales service.All our products have 1 year warranty period.

4.If need,we are able to travel with customer to visit our factories.

5.We believe "customer is God ,quality is our unchangeable commitment".

Company Information

Henan Lite RefroactoryMaterial Co., Ltd is specialized in refractory manufacture,Engineering construction,also new technology research & popularization and application for high temperature industrial furnace.The company possess the independent import & export certification ,service the customers domestic & worldwide.The company have a strong technical force,Cultivated first -class team whom possess rich experience of technological innovation&engineering design and construction for refractory enigineering major project. In the technological team there are more than 10 senior research design personnel own the Advanced Level Accountant,more than 10 personnel are engineer ,and more 20technicians.

Company main business products: corundum mullite brick, BF with high alumina brick, clay brick for blast furnace, hot blast stove with thermal shock low creep high alumina series, hot blast stove with thermal shock clay brick and mechanism of low creep refractory ball, light thermal insulation series, special refractory brick acid, low porosity, high and soft feature a firebrick, refractory wear can be plastic, wear fire-resistant castable etc.

Our value include innovation, creativity, craftsmanship, and technical skill. We are dedicated to providing the best quality service to our customers. We will continue our efforts to be responsive to the needs of our clients.

Welcome to visit our factory.

corporation charter

Henan Lite Refroactory Co., Lt is specialized in the production, construction, new technology research and development and popularization and application of refractory materials for industrial high temperature furnace. Our company has a professional enterprise qualification and win more business honor.

Customer visit

Our company attaches great importance to the construction of service platform, business network has covered various provinces and cities nationwide, and to promote to Iran, Turkey, Vietnam, Malaysia, India, Kazakhstan and other countries.

Advantage

1. We have been in this industry for over 30 years, with the most professional production technology.

2. Our company to provide the best quality service, at any time for the customer to solve the problem.

3. We have an experienced team of work and production base.

4.We offer the highest quality products and competitive prices.

5. We have a professional enterprise qualification certification and product inspection certificate.

6. We have effective logistics centers, factories and warehouses to ensure fast delivery of the domestic market and foreign markets.

FAQ

1.Why choose us?

- We had been in this line for more than 30 years.

- Our products have been exported to Asia Southeast America North customer recognition.

- We offer competitive prices.

- We can provide customers with a reliable and efficient service.

2.Do we supply samples?

- Yes,we would like to offer any free sample you required.

3.What is MOQ?

- MOQ may vary by customer's special requirement,we try our best to meet your businessre quirement.

4.Can the clients visit your factory?

- Of course,we accpet size and color customized.

5.Can the clients visit your factory?

- Of course ,welcome to visit our factory any time.

6.Which payment terms do you accept?

- L/C

- T/T

- Westen Union

7.After an order is placed,when to deliver?

10~30days.

8.How to ensure the quality of shipping products?

- All produsts have to be through strict inspection before delivery.

- We not only have to ensure the quality in business but also the credibility in our market.

9.Which certifications do your company have ?

- ISO9001 and Test Report,we could provide other necessary certifications if required.

Contact us

Contact

Supplier