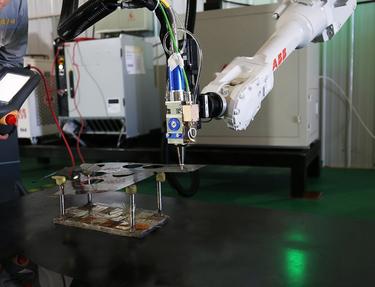

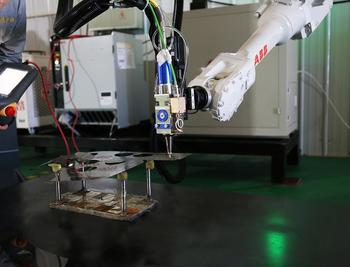

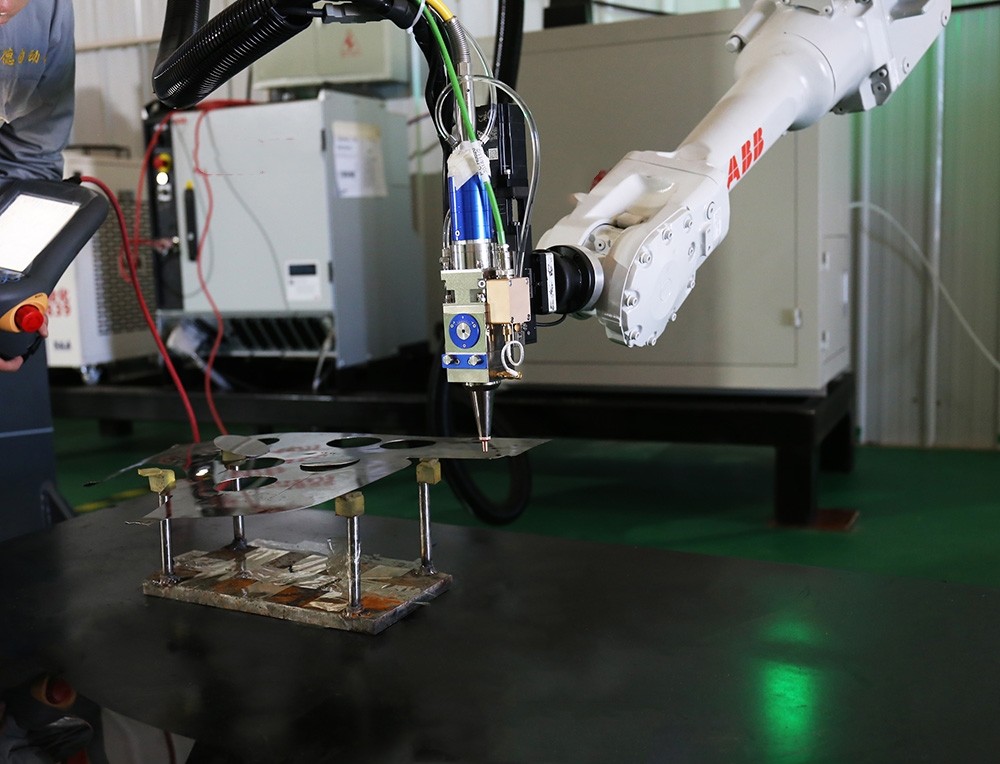

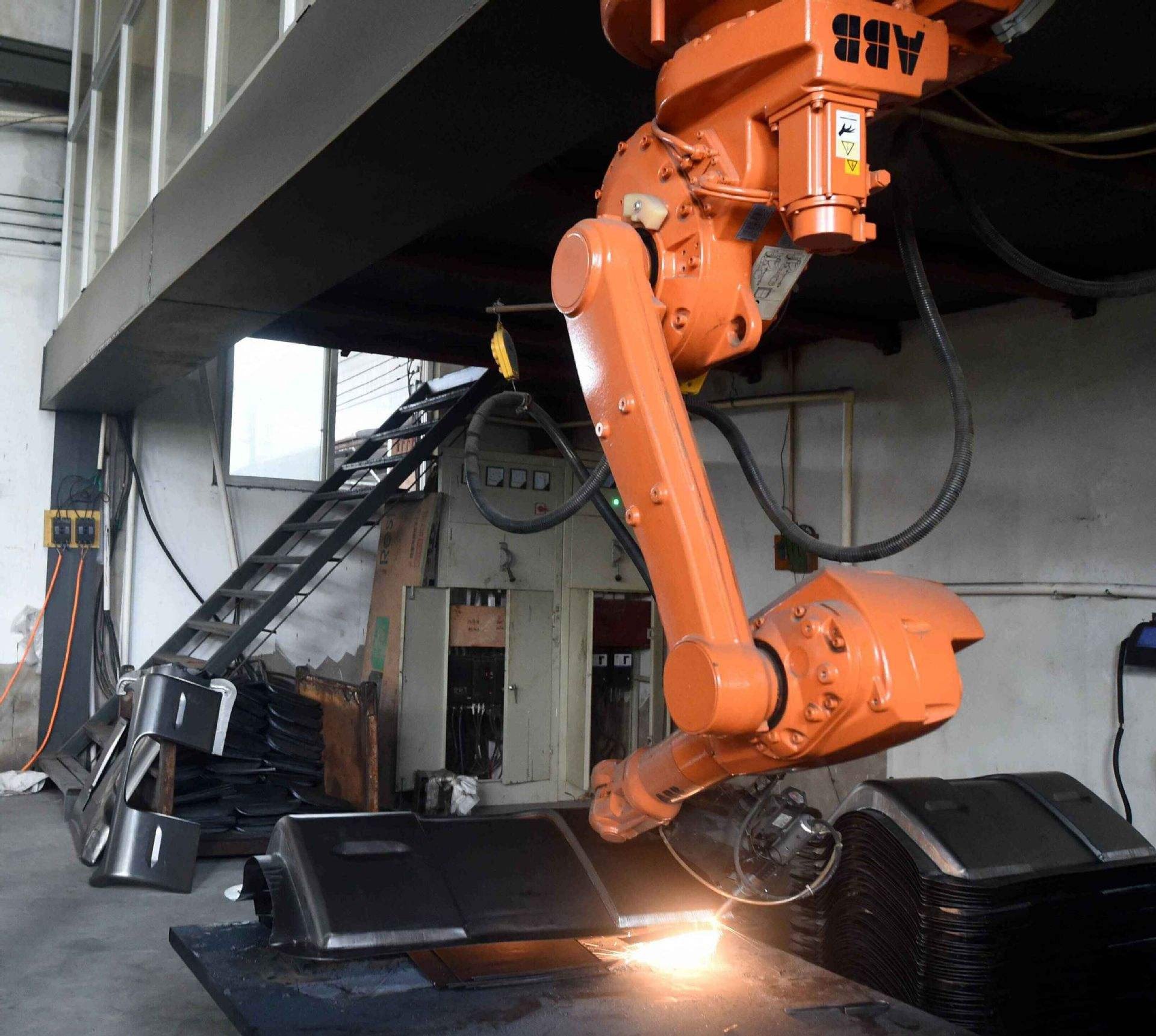

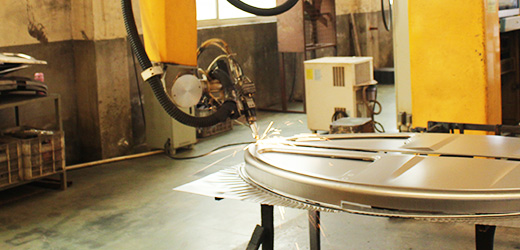

Through independent innovation and technological research and development,LASERAE Automation introduced a three-dimensional fiber laser cutting machine that uses a gantry fixed upside-down robot or a vertical fixed robot base, a fiber laser to flexibly transmit high-quality lasers to the cutting head, and independently developed PLC integrated control robots, lasers And other parts for special-shaped processing of automotive three-dimensional parts.This equipment mainly produces parts with a thickness of 0.5-6mm. It has the characteristics of convenient processing of three-dimensional parts, low investment cost, low use cost and maintenance, and simple operation. The launch of LASERAE 3D laser cutting machine broke the monopoly of the foreign market in the automotive industry. It replaced traditional processing methods, reduced mold investment, greatly shortened the development cycle of automobile manufacturers and component suppliers, and improved processing efficiency And the precision of cutting the workpiece reduces the production cost.

3D Robot Fiber Metal Laser Cutting Machine

Fast Laser cutting speed,shorten product production cycle

Fiber laser generators are more efficient than Co2 lasers in energy conversion efficiency, so they are more energy efficient and cost effective. The compiled program no longer leaves the manual correction amount, but is a 3D processing program that is completely consistent with the theoretical trimming line. It is directly used for cutting products. It can ensure that the cutting process is always consistent with the actual trimming state

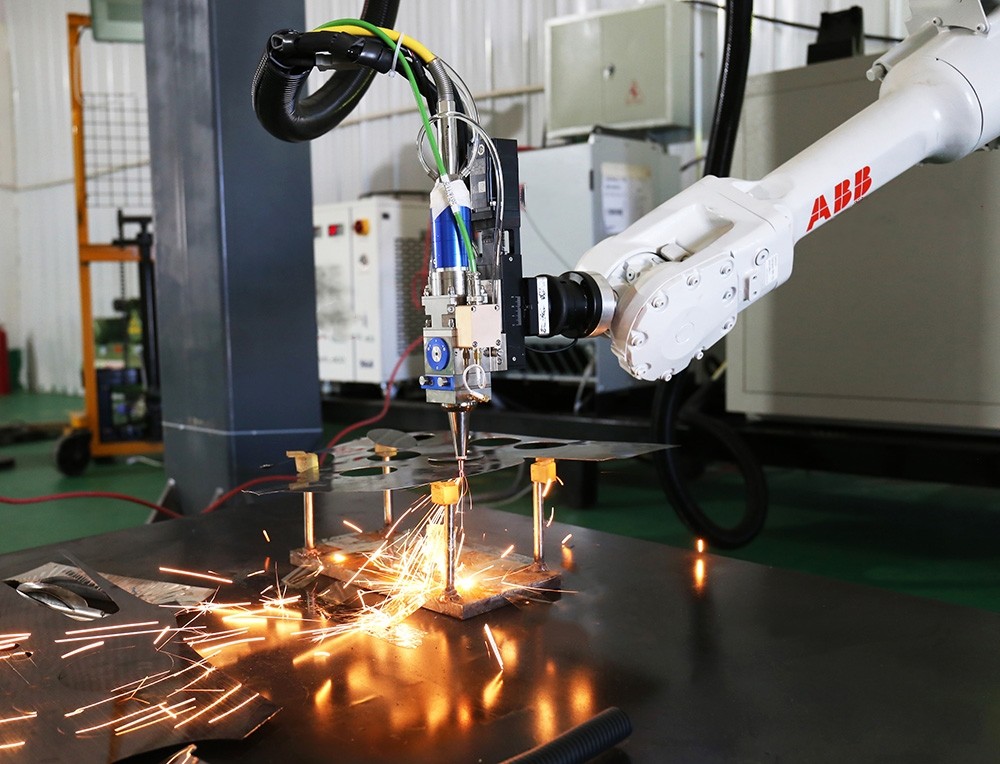

Narrow cutting slit,good cutting quality

Because the traditional mechanical knife is replaced by an invisible light beam, the mechanical part of the laser cutter head has no contact with the work and will not cause scratches on the work surface during the work; the heat affected zone of the cutting is small, the deformation of the plate is small, and the slit is narrow 0.1mm ~ 0.3mm);

High degree of automation and easy operation

Programming control system, human-machine interface operation is more clear and simple, high degree of automation and more humane. The program compiled by the engineer is very clear and intuitive. As long as the operation manual is optimistic, the operator can use it after short-term training.

No pollution during processing

During the fiber laser processing, there is no harmful gas, noise and danger. Concentrated laser beam without heat diffusion greatly improves the working environment for operators.

No tool wear during processing and long life time

Because it is non-contact processing, the energy and moving speed of the high energy laser beam can be adjusted. There is no need to change tools, and it is not necessary to calculate the amount of tool wear, which is simpler to use.

FHigh processing reliability,strong stability,and basically maintenance freeFiber laser has the characteristics of small size, low energy consumption, long life, high stability, maintenance-free, multi-band, green environmental protection, etc. It has superior beam quality, stable performance, and ultra-high photoelectric conversion efficiency.

Robot Brand |

Model |

Max, Reaching radius |

load |

Re-positioning accuracy |

Actual cutting accuracy | Feature |

ABB |

2600 |

1650mm |

20Kg |

±0.04mm |

±0.13mm | Recommended, suitable for precision cover cutting, large cutting area, good at ultra-deep workpieces, high cost performance |

kawasaki | RS020N | 1725mm | 20kg | ±0.04mm | ±0.2mm | |

Staubli | RX160L | 2010mm | 28kg | ±0.05mm | ±0.1mm | Suitable for high precision cutting occasions |

Widely used in various manufacturing industries such as aerospace, automobile manufacturing, lamp manufacturing, mold manufacturing, medical equipment, hardware, decoration, kitchenware, metal external processing services, etc.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts