1.Concentrated heat, short heating time only 0.02 seconds, small welding distortion.

2. The control system has high consistency and can quickly adjust to the specification. The operation is simple and convenient and the production efficiency is high.

3. Rapid formation of nugget, non-protected gas, and non-welded filler brazing.

4. The production environment is free from pollution, the production cost is low, and an automated operation mode can be realized.

5. The control function can be set to complete the length of time, 10 sets of standard parameters storage is equipped with three sections of current independent detection and can set the upper and lower limits.

6. Suitable for welding low carbon steel, stainless steel, copper and other metals.

7. Applicable industries: automotive, aerospace, electronics, military, electronics, household appliances, kitchenware, hardware, etc.

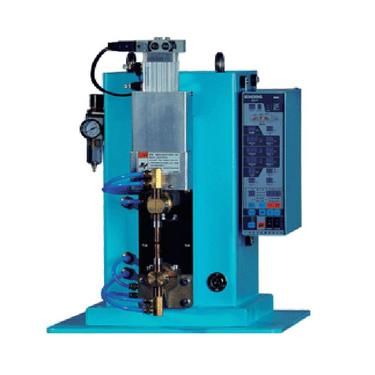

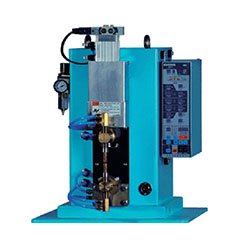

Aerodynamic Constanat Current Protruding Welding Machine Resistance Welding Machine

Desk-type AC spot and projection welding machine HSSP-16ST

Desk-type AC spot and projection welding machine HSSP-16ST Desk-type AC spot and projection welding machine HSSP-25ST

Desk-type AC spot and projection welding machine HSSP-25ST Vertical AC spot and projection welding machine HSSP-40

Vertical AC spot and projection welding machine HSSP-40 Vertical AC spot and projection welding machine HSSP-100

Vertical AC spot and projection welding machine HSSP-1001.AC spot and projection welding machine, also known as resistance welding machine, is one of the most energy-saving, fastest and environmental friendly advanced welding equipment since the 19th century.

2.The operation principle of AC spot and projection welding machine: by electrifying the welded metal, part of the machine is melted because of the resistance generated by electric current flowing through the metal, and then a nugget is formed through welding under the pressure.

3.AC spot and projection welding machine is divided into: AC spot welding machine and AC projection welding machine.

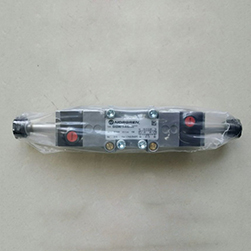

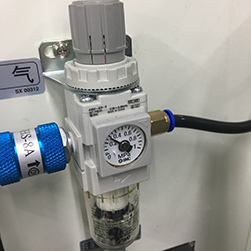

4.AC spot and projection welding machine is consisted of welding transformer, thyristor, controller, solenoid valve, cylinder, copper processing parts, iron castings, chassis and other elements.

Goodweld Product Show

Goodweld Configure Show

Goodweld Product Introduce

Product Parameter

| Rated | Electric | Input | Duty | Electrode | Electrode | Arm extend | Cooling |

| KW | Uf | V | % | KN | mm | mm | L/min | |

HSSP-16ST | 16 | 11 | 380 2PH | 50% | 0.5/0.8 | 25 | 100 | 6 |

HSSP-25T | 25 | 12 | 380 2PH | 50% | 0.5/0.8 | 25 | 150 | 6 |

HSSP-16 | 16 | 11 | 380 2PH | 50% | 3.0 | 50 | 350 | 12 |

HSSP-25 | 25 | 12 | 380 2PH | 50% | 3.0 | 50 | 380 | 15 |

HSSP-40 | 40 | 16 | 380 2PH | 50% | 3.0 | 50 | 380 | 15 |

HSSP-63 | 63 | 18 | 380 2PH | 50% | 3.0 | 50 | 380 | 15 |

HSSP-80 | 80 | 22 | 380 2PH | 50% | 3.0 | 50 | 380 | 15 |

HSSP-100 | 100 | 27 | 380 2PH | 50% | 3.0 | 60 | 350 | 30 |

HSMD-150 | 150 | 34 | 380 2PH | 50% | 3.0 | 60 | 350 | 30 |

HSSP-200 | 200 | 38 | 380 2PH | 50% | 3.0 | 60 | 350 | 45 |

HSSP-250 | 250 | 44 | 380 2PH | 50% | 3.0 | 60 | 350 | 50 |

The advantages of AC spot and projection welding machine

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts