1. Transformer for MF inverter DC Spot Welding Machine, with a duty cycle of 50%, increase from 380V/three-phase 50/60Hz to 1000Hz , using a special core to reduce the weight of the core material, transformer can be used for a very long time.

2. The control system of MF inverter DC Spot Welding Machine is operated with a touch screen, which is easy to operate, quickly enters the specification, and improves production efficiency.

3. Current of MF inverter DC Spot Welding Machine with full digital closed-loop circuit is stable(current detection in real time) ; we can set the current value;when 100A as a start and (core) current climb speed of 2 milliseconds , it can reach the set value;the current is more stable.

4. The function of time control for MF inverter DC Spot Welding Machine can set the length of completion time; RS8421 code calls the welding specification; 99 sets of standard parameter storage have three sections of current independent detection and set the upper and lower limits.

5. Real-time communication between the two communication ports (RS232 and RS485) of the MF controller, modBUS standard protocol. It operates faster when used in production of automation and robot.

6. Real-time detection and display of the current waveform, more stable current monitoring, can be used for automated detection. High-power German IGBT makes pre-testing, testing whether it’s in correct status before welding .

7.Welding process of aluminum plate and galvanized plate for MF inverter DC Spot Welding Machine,The AC spot welding machine takes two currents to start welding and produce big splashes. However, by using MF inverter DC Spot Welding Machine to weld aluminum or galvanized sheet, the weld joint looks beautiful and smooth and during welding process there are only small splashes, minor damage to zinc coating and oxide layer, and less wear to welding electrode.

Resistance Welding Machine Mash Welder Spot Welding Machine Non-Standard Customization

MF inverter DC Spot and Projection Welding Machine is one of the most advanced resistance welding machines in the resistance welding field since 19th century. MF inverter DC Spot and Projection Welding Machine is known as MF inverter DC resistance welding machine. Its two key components are MF transformers and MF inverter controllers. Its working principle is that firstly three-phase 380V alternating current across through MF transformer, this process increases frequency from 50/60HZ to 1000HZ-5000HZ after rectified and filtered ; then across through the inverter and high power diode rectifier, this rectified process buck into a stable DC power, supplying to the welding electrode.

Advantages of MF inverter DC Spot Welding Machine:

1. Welding time is as short as 0.2ms-1ms, welding accuracy is as high as 0.2ms-1ms, affected area by welding heat is small, deformation after welding is small, welding spatter can be effectively controlled, and welding nugget with stable and high standards can be obtained.

2. Balanced three-phase input , small impact on the grid network pressure, high power factor can obtain more than 90% of the power value, less loss. Because the energy of MF inverter DC Spot and Projection Welding Machine is concentrated, welding spatter is rarely generated under the influence of the clustering effect, and the service life of the electrode is improved by more than 5 times.

Goodweld Product Show

Three heads MF Inverter Spot Welding Machine HSMD-250

Three heads MF Inverter Spot Welding Machine HSMD-250 MF Inverter Spot Welding Machine HSMD-160

MF Inverter Spot Welding Machine HSMD-160 MF Inverter Spot Welding Machine HSMD-400

MF Inverter Spot Welding Machine HSMD-400 MF Inverter Spot and Projection Welding Machine HSMD-500

MF Inverter Spot and Projection Welding Machine HSMD-500 MF Inverter Fast Spot Welding Machine HSMD-120

MF Inverter Fast Spot Welding Machine HSMD-120 MF Inverter Precision Spot Welding Machine HSMD-100ST

MF Inverter Precision Spot Welding Machine HSMD-100ST MF Inverter Spot with no Mark Welding Machine HSMD-200

MF Inverter Spot with no Mark Welding Machine HSMD-200 MF Inverter DC Spot Welding Machine Double Stroke HSMD-80

MF Inverter DC Spot Welding Machine Double Stroke HSMD-80 MF Inverter DC Spot Welding Machine HSMD-100

MF Inverter DC Spot Welding Machine HSMD-100

MF Inverter Precision Spot Welding Machine HSMD-200ST

MF Inverter Inverter Projection Welding Machine HSMD-300

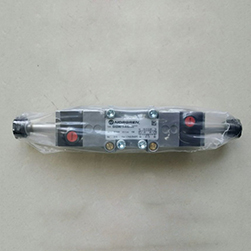

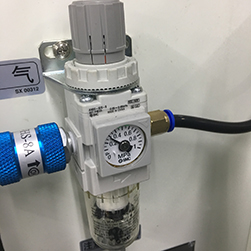

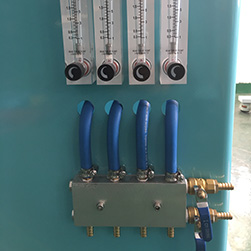

Goodweld Configuration Show

Goodweld Product Introduce

Product Parameter

| Rated | Maximum welding current | Input | Duty | Electrode | Electrode | Arm extend | Cooling |

| KW | KA | V | % | KN | mm | mm | L/min | |

HSMD-100ST | 50 | 10 | 380 3PH | 50% | 0.5/0.8 | 25 | 100 | 6 |

HSMD-250ST | 80 | 25 | 380 3PH | 50% | 0.5/0.8 | 25 | 150 | 6 |

HSMD-80 | 80 | 20 | 380 3PH | 50% | 3.0 | 50 | 350 | 12 |

HSMD-100 | 100 | 28 | 380 3PH | 50% | 3.0 | 50 | 380 | 15 |

HSMD-120 | 120 | 30 | 380 3PH | 50% | 3.0 | 50 | 380 | 15 |

HSMD-160 | 160 | 30 | 380 3PH | 50% | 3.0 | 50 | 380 | 15 |

HSMD-200 | 200 | 55 | 380 3PH | 380 | ||||

HSMD-250 | 250 | 60 | 380 3PH | 50% | 4.5/7.5 | 60 | 350 | 30 |

HSMD-300 | 300 | 65 | 380 3PH | 50% | 12 | 60 | 350 | 30 |

HSMD-400 | 400 | 70 | 380 3PH | 50% | 18 | 60 | 350 | 45 |

HSMD-500 | 500 | 80 | 380 3PH | 50% | 28 | 60 | 350 | 50 |

Advantages of MF inverter DC Spot and Projection Welding Machine:

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts